Tooth surface quenching device for rack

A technology of quenching device and rack, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of easy deformation of rack, difficult to observe, end upturning, etc., to ensure quality, improve effect, facilitate recycling and other problems. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

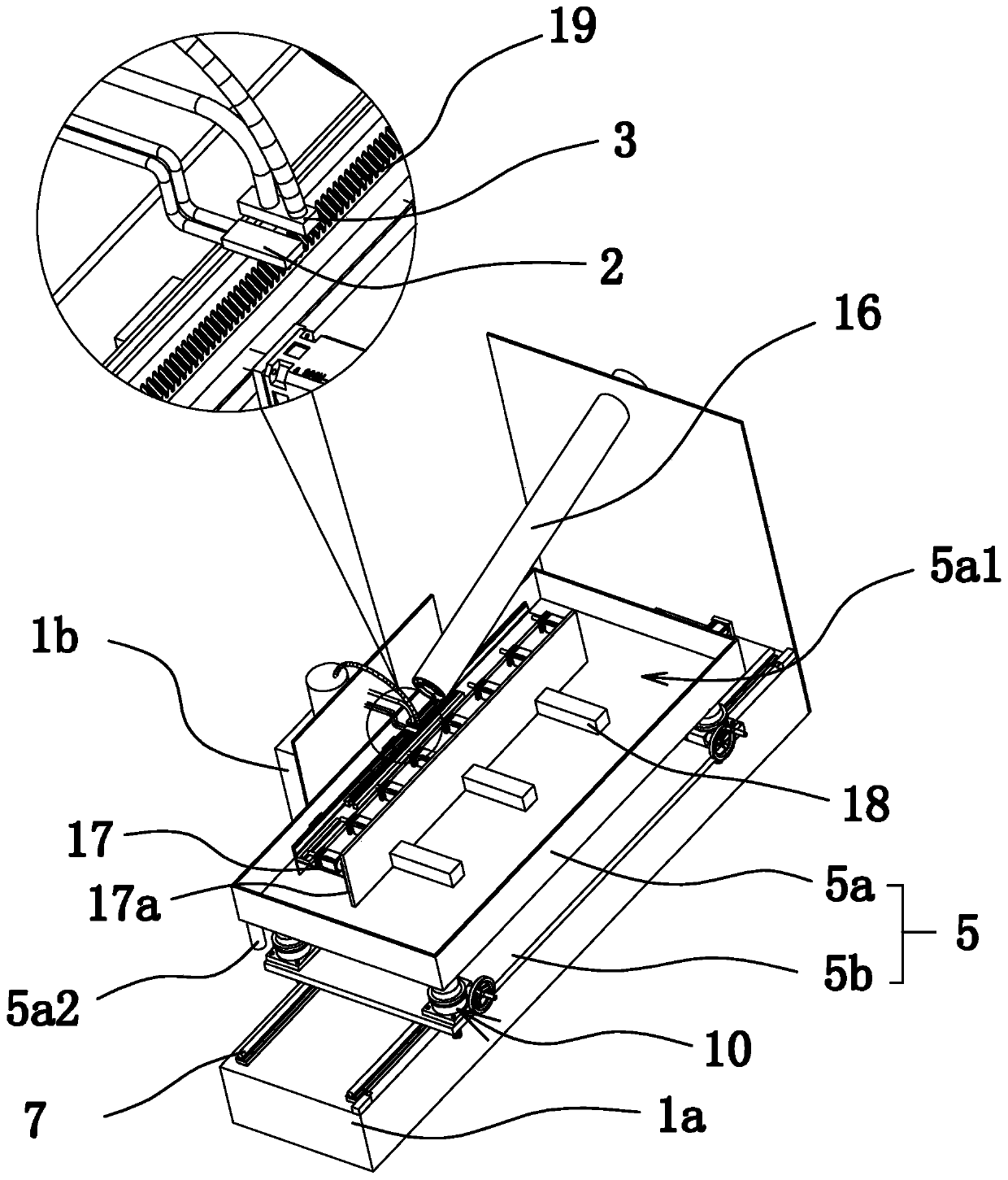

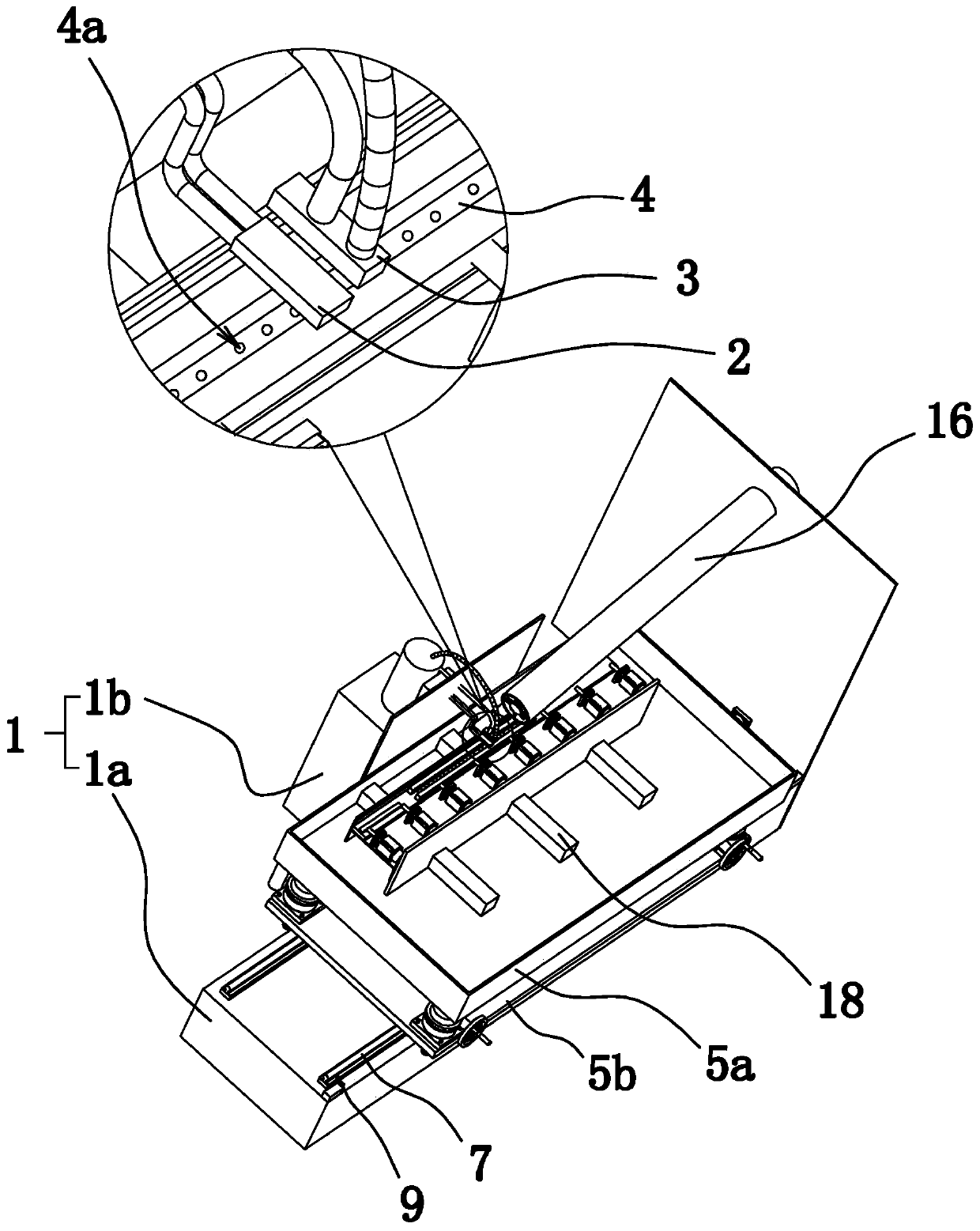

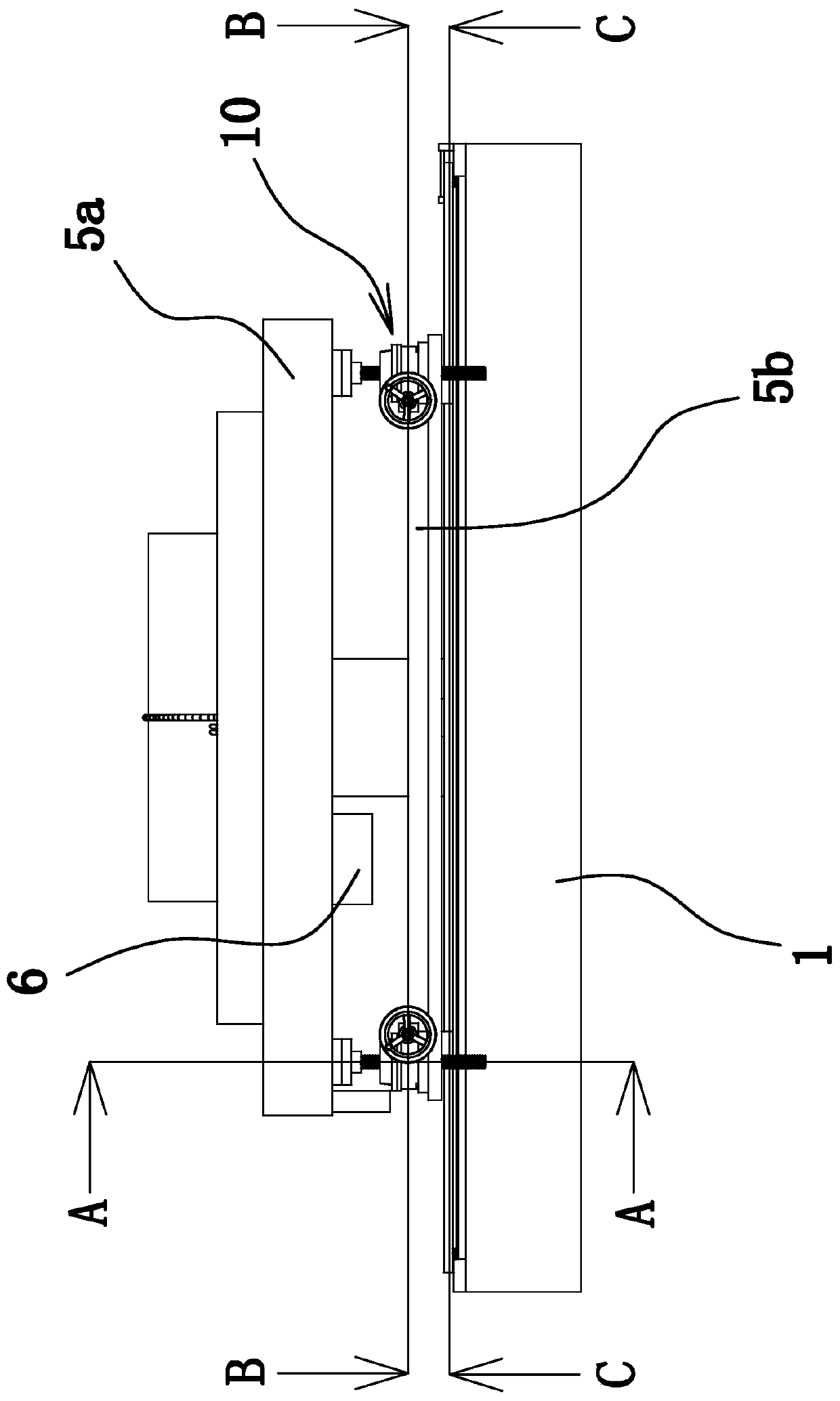

[0034] Such as Figure 1-6 As shown, the tooth surface quenching device of the rack includes a frame 1, a quenching head 2, a quenching liquid nozzle 3, a clamp 4 for clamping and positioning the rack 19, and a quenching plate 5 with a mounting cavity 5a1. Frame 1 includes frame body one 1a and frame body two 1b, frame body one 1a and frame body two 1b are arranged separately, frame body two 1b is provided with a liquid storage tank for storing quenching liquid, quenching head 2 and quenching liquid nozzle 3 are all fixed on the frame 1, and the quenching liquid nozzle 3 communicates with the liquid storage tank.

[0035] The quenching tray 5 includes a base plate 5b and a disc-shaped disc body 5a, and the disc body 5a is arranged on the base plate 5b. A slide rail 7 is fixed on the frame body 1a, and there are two slide rails 7. Sliders 8 are provided on the bottom of both sides of the base plate 5b, and the slide blocks 8 are slidably connected on the slide rails 7. The dr...

Embodiment 2

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that the adsorbent is an electromagnetic chuck, the electromagnetic chuck is elongated and arranged at the bottom of the fixture 4, and the magnetically conductive panel of the electromagnetic chuck is flush with the bottom surface of the fixture 4 flat. The rack 19 is clamped and positioned in the fixture 4, and is attached to the bottom surface of the fixture 4 and the magnetically conductive panel of the electromagnetic chuck. The electromagnetic chuck generates magnetic force through the internal coil energization, and the rack 19 is firmly sucked by the magnetically conductive panel. Make it always keep close to the bottom surface of the fixture 4, therefore, in the quenching process, even if the rack 19 is heated, it will not be deformed and upturned, which improves the quenching effect of the tooth surface and ensures the quality of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com