A system and method for drying and high-efficiency co-firing treatment of high-moisture solid waste

A high-moisture, drying technology, used in dewatering/drying/concentrating sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as furnace corrosion damage, affecting combustion stability, etc. Achieve the effects of non-polluting emissions, reducing carbon content in fly ash, and increasing heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

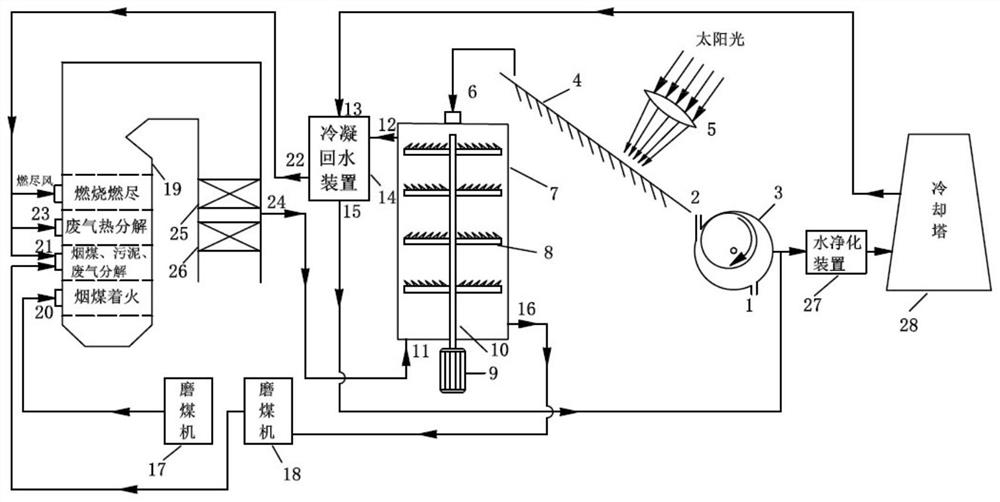

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

[0029] see figure 1, a system for high-moisture solid waste drying and high-efficiency co-firing treatment provided by the present invention includes an extrusion dehydration part composed of a sludge inlet 1, an eccentric extrusion dehydration device outlet 2, and an eccentric extrusion dehydration device 3; metal Chain conveyor belt 4, solar preheating drying part composed of Fresnel lens 5; gas dryer inlet 6, gas dryer 7, serrated scraper 8, motor 9, drive shaft 10, dryer gas inlet 11 , dry exhaust gas outlet 12, flue gas dryer sludge outlet 16, flue gas convection heat exchange drying part composed of boiler tail flue exhaust port 24, the exhaust part is selected between the high temperature economizer 25 and the low temperature economizer 26 area; circulating water inlet 13, condensing water return device 14, recycled water and circulating water outlet 15, water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com