Light conversion biaxially oriented polyester film

A biaxially oriented polyester, light conversion technology, applied in the application, coating, household appliances and other directions, can solve the problems of poor light conversion ability and single function of the film, and achieve enhanced utilization, good transparency, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings. The following embodiments are only exemplary, and not all of the technical solutions of the present invention.

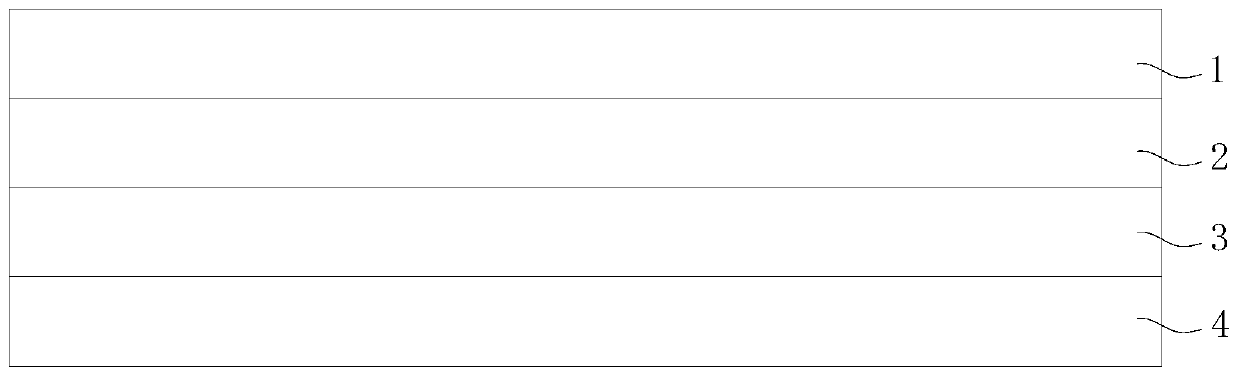

[0035] Such as figure 1 As shown, a light conversion biaxially stretched polyester film, the light conversion biaxially stretched polyester film is as follows from top to bottom: antistatic layer 1, first functional layer 2, light conversion layer 3, second functional layer 4;

[0036] Wherein, the components of the first functional layer 2 and the second functional layer 4 are: 60% to 70% of optical grade polyester particles, 0% to 10% of anti-shrinkage agent, 20% to 30% of polyester Ester chips;

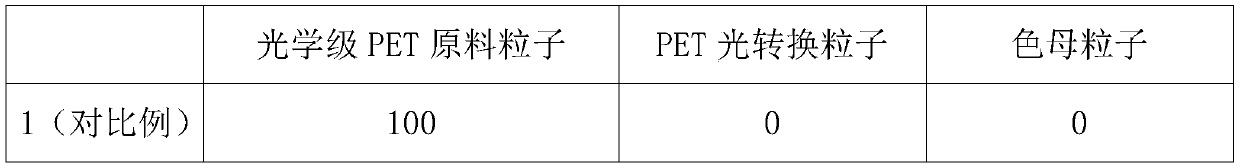

[0037] The components of the light conversion layer 3 are: 60% to 80% of optical-grade PET raw material particles, 20% to 35% of PET light conversion particles, and 0% to 3% of masterbatch particles.

[0038] The antistatic layer 1 includes RU-92-208 resin, AC-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com