Nitrogen-doped reduced graphene oxide nano composite material and preparation method and application thereof

A nano-composite material and graphene technology are applied in the field of nitrogen-doped reduced graphene oxide nano-composite materials and their preparation, and can solve the problems of high energy consumption and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

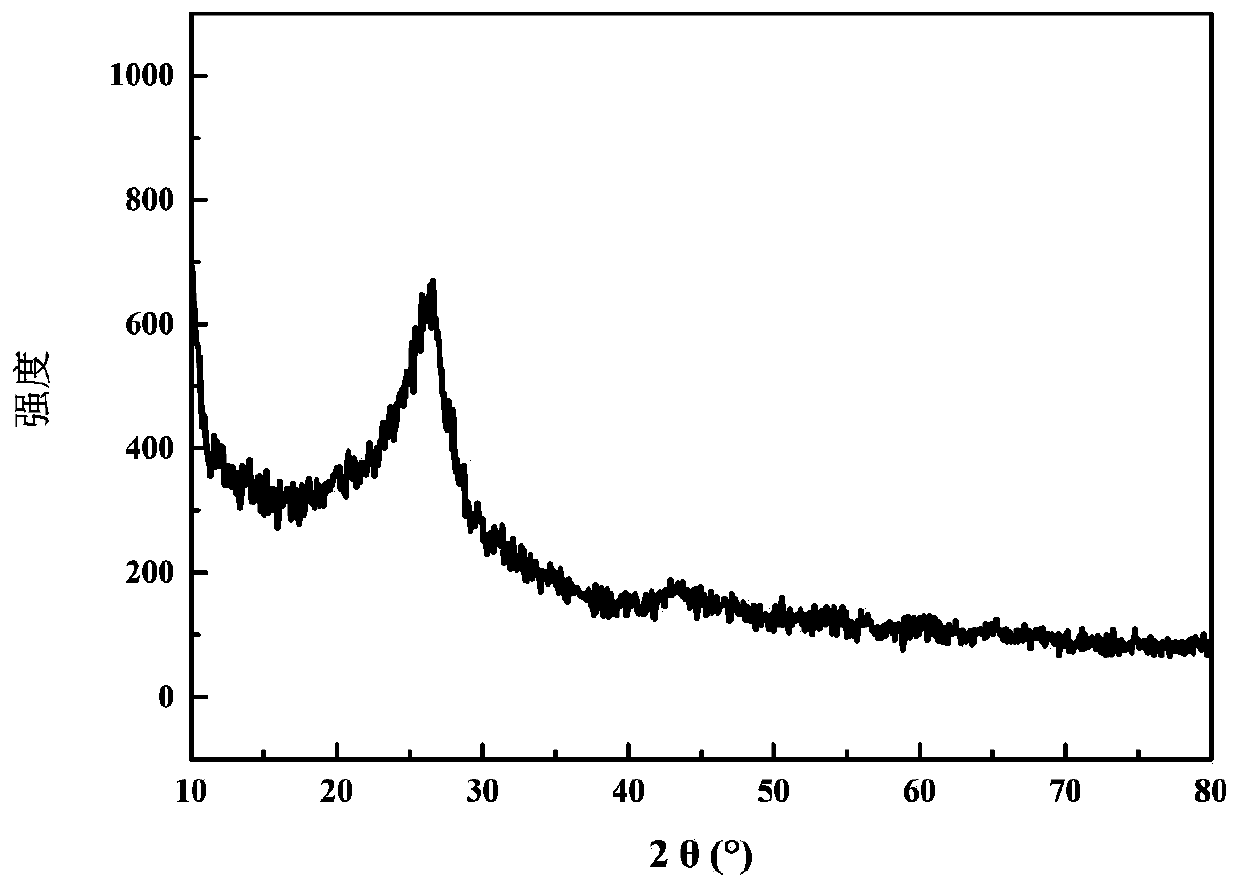

[0030] The invention provides a method for preparing a nitrogen-doped reduced graphene oxide nanocomposite material, comprising the following steps:

[0031] Chitosan, glacial acetic acid and water are mixed to obtain chitosan acetic acid aqueous solution;

[0032] Mixing graphene oxide and water to obtain a graphene oxide aqueous dispersion;

[0033] The chitosan acetic acid aqueous solution and graphene oxide aqueous dispersion are mixed, freeze-dried to obtain chitosan / graphene oxide powder;

[0034] The chitosan / graphene oxide powder is subjected to a thermal reduction reaction to obtain a nitrogen-doped reduced graphene oxide nanocomposite material.

[0035] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in the field or prepared by conventional preparation methods in the field.

[0036] The invention mixes chitosan, glacial acetic acid and water to obtain chitosan acetic acid aqueous solution...

Embodiment 1~3

[0057] Weigh 1g of chitosan, 1mL of glacial acetic acid and 200mL of deionized water to prepare chitosan acetic acid aqueous solution; weigh 1g of graphene oxide and 200mL of deionized water, and ultrasonically disperse graphene oxide in deionized water to prepare graphene oxide The aqueous dispersion is ready for use.

[0058] According to the dropping speed of 2mL / min, the chitosan acetic acid aqueous solution was slowly added dropwise into the graphene oxide aqueous dispersion, and stirred for 10 hours at 60°C to form a uniform mixed system, and then the mixed system was placed in- In a freeze dryer at 30°C, freeze-dry for 72 hours to obtain chitosan / graphene oxide powder.

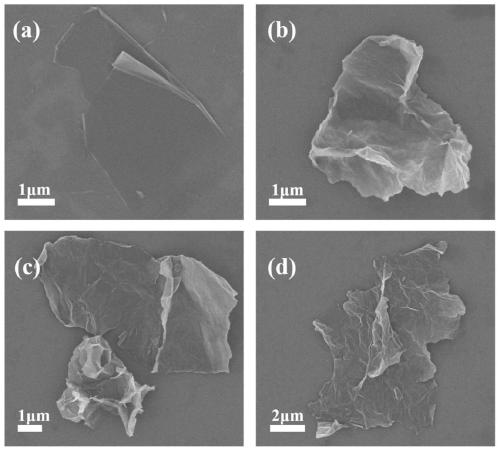

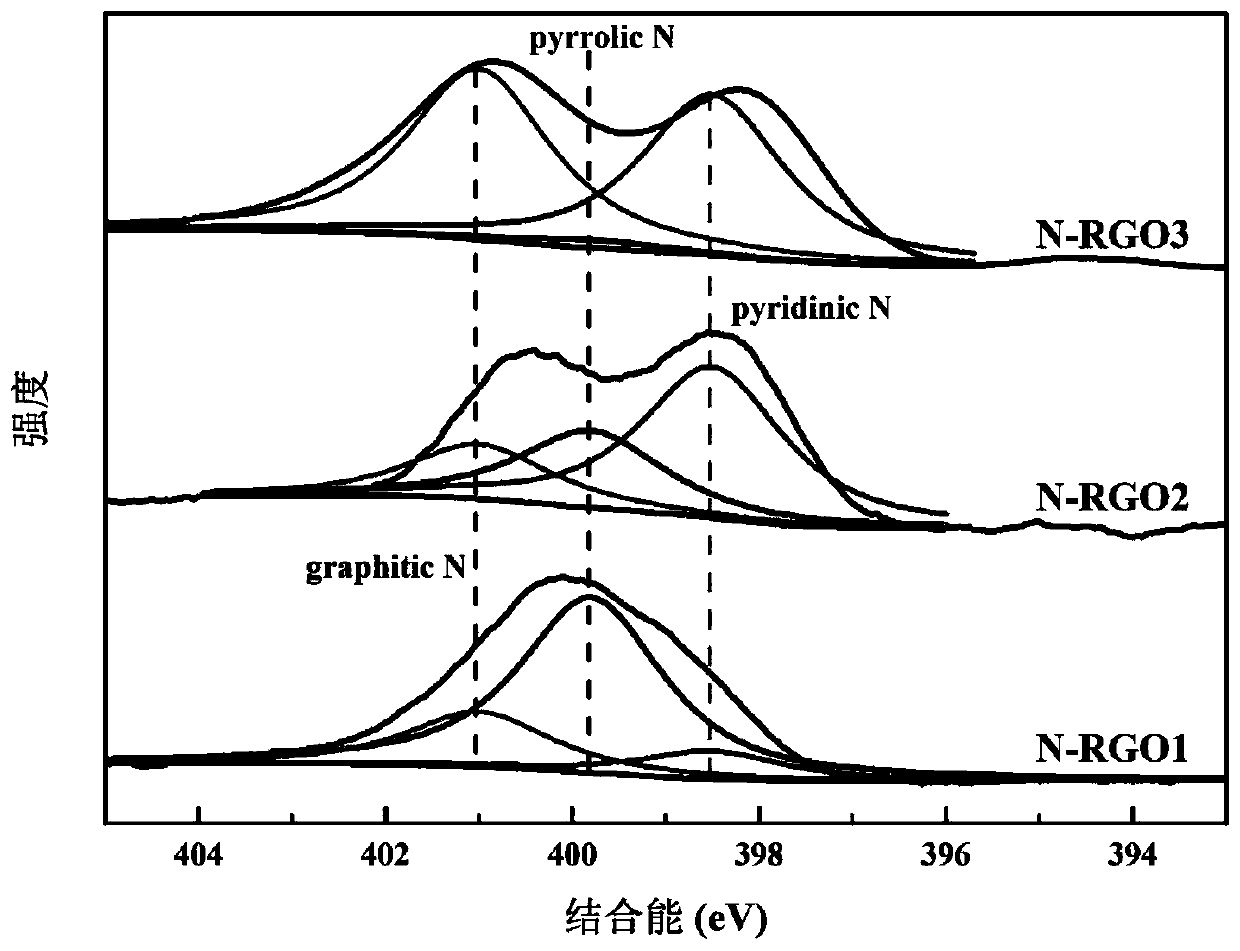

[0059] The obtained chitosan / graphene oxide powder was placed in a tube furnace for thermal reduction reaction under a nitrogen atmosphere. The thermal reduction reaction temperatures were controlled at 250°C, 500°C and 750°C, respectively, and the thermal reduction reaction time was controlled at 4h. ...

Embodiment 4~6

[0069] Be 1g:1mL:200mL ratio by weighing chitosan, glacial acetic acid and deionized water and be mixed with chitosan acetic acid aqueous solution; Be 1g:200mL ratio by weighing graphene oxide and deionized water Water, ultrasonically disperse graphene oxide in deionized water to prepare graphene oxide aqueous dispersion for later use.

[0070] According to the dropping speed of 2mL / min, the chitosan acetic acid aqueous solution was slowly added dropwise into the graphene oxide aqueous dispersion, and stirred for 10 hours at 60°C to form a uniform mixed system, and then the mixed system was placed in- In a freeze dryer at 30°C, freeze-dry for 72 hours to obtain chitosan / graphene oxide powder.

[0071] The obtained chitosan / graphene oxide powder was placed in a tube furnace for thermal reduction reaction under a nitrogen atmosphere, the thermal reduction reaction temperature was controlled at 750 °C, and the thermal reduction reaction time was controlled at 2h, 4h and 6h, respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com