Device for detecting insulating property of vacuum coating nano-film layer of mobile phone rear cover

A technology of vacuum coating and mobile phone back cover, which is applied in the direction of measuring devices, conveyors, measuring electronics, etc., can solve the problems of increasing defective products, increasing labor costs, and wasting manpower, so as to reduce labor costs and increase defective products rate, the effect of improving the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

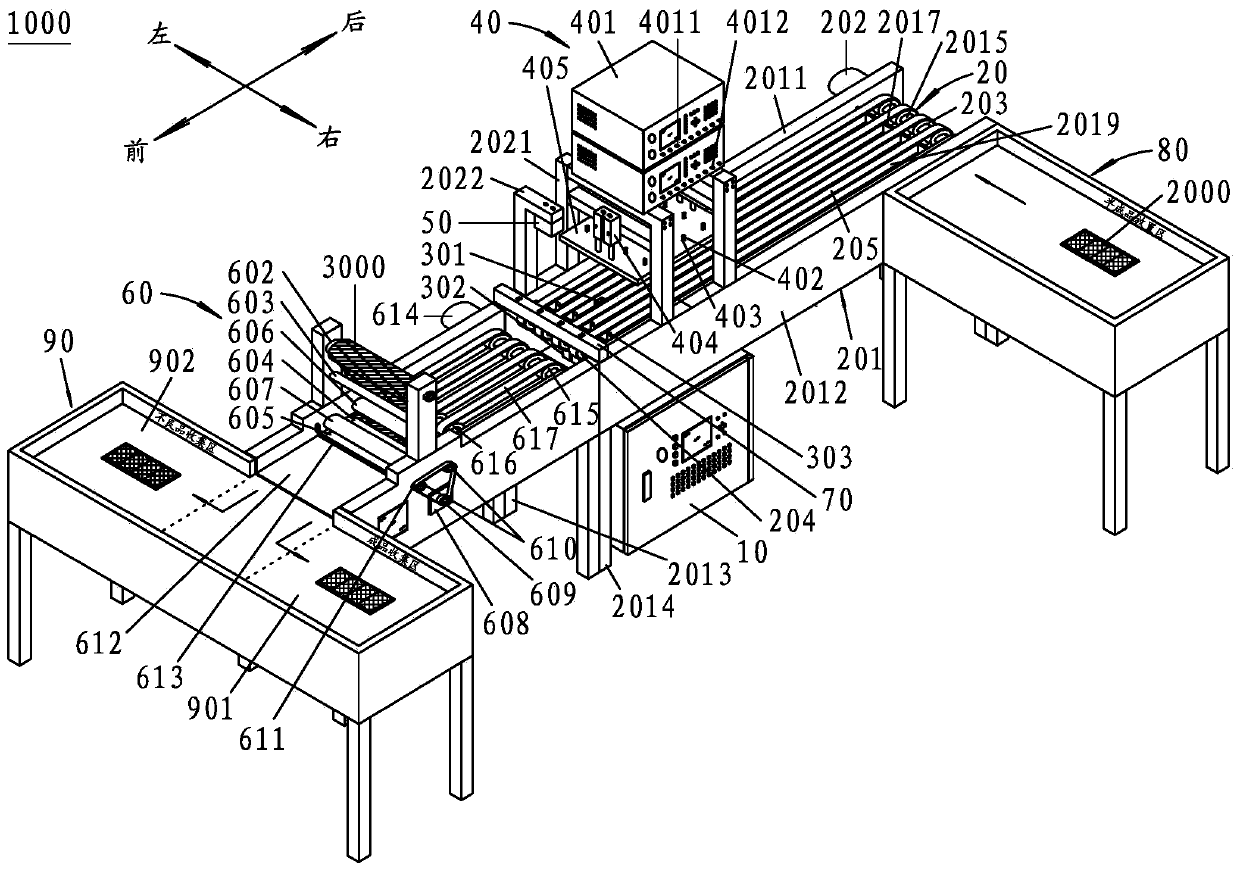

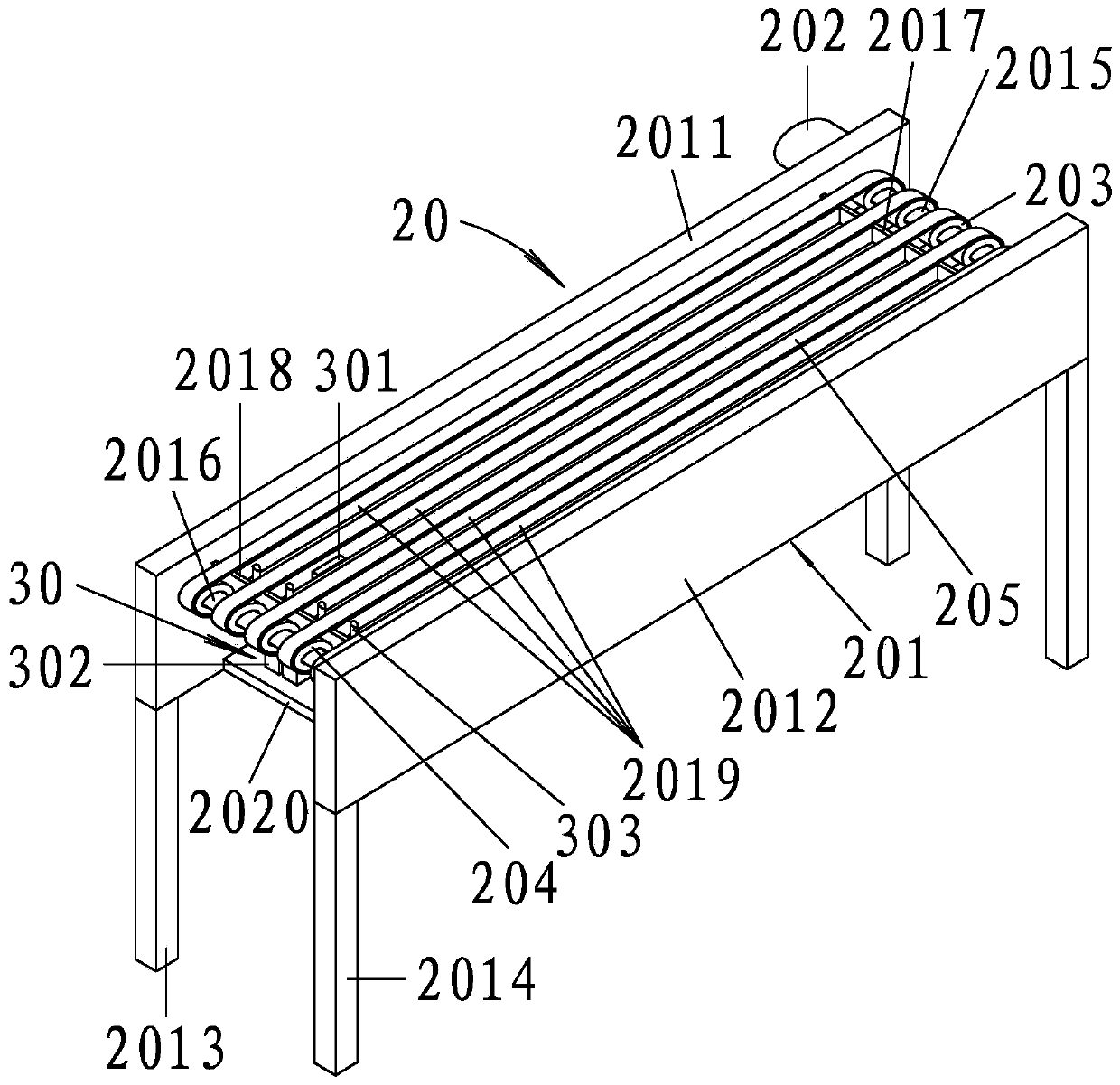

[0069] combine Figure 1-Figure 10 shown;

[0070] The device 1000 for detecting the insulation performance of a vacuum-coated nano-film layer on the back cover of a mobile phone provided by the present invention is mainly used to detect the insulation performance of the vacuum-coated nano-film layer on the back cover of a mobile phone during specific implementation. It includes a main controller 10 ,Also includes:

[0071] Incoming material conveying device 20; said incoming material conveying device 20 is arranged along the front and back directions, and is connected with said main controller 10, in order to convey forward the incoming material 2000 of vacuum coating mobile phone back cover;

[0072] Incoming material sensing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com