Liquid metal sampler and liquid metal sampling method

A liquid metal and sampler technology, applied in sampling, sampling devices, instruments, etc., can solve the problems of sampling samples mixed with impurities, inappropriate operation of sampling instruments, improper operation, etc., and achieve convenient processing and production, convenient sampling, and compact and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

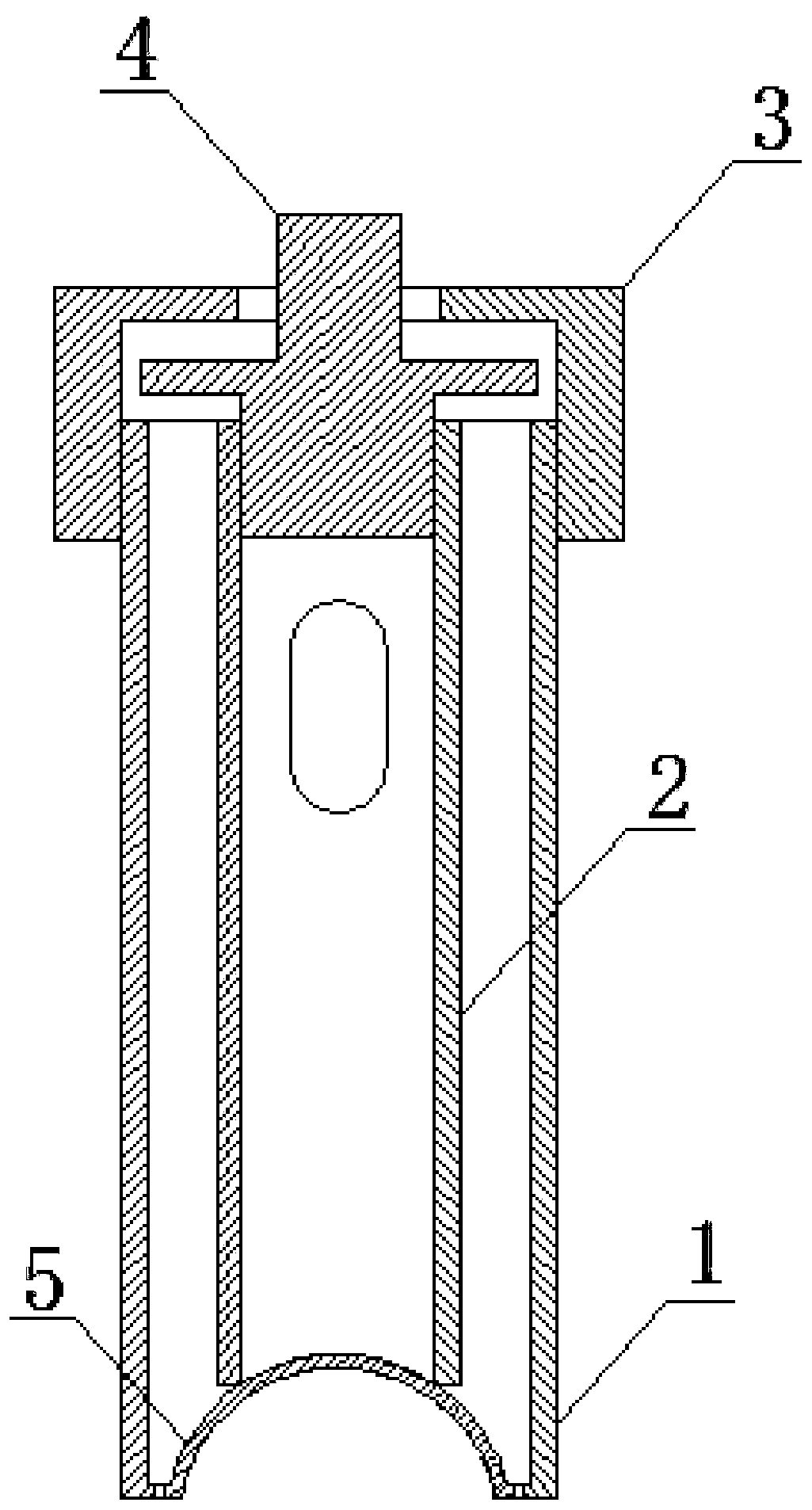

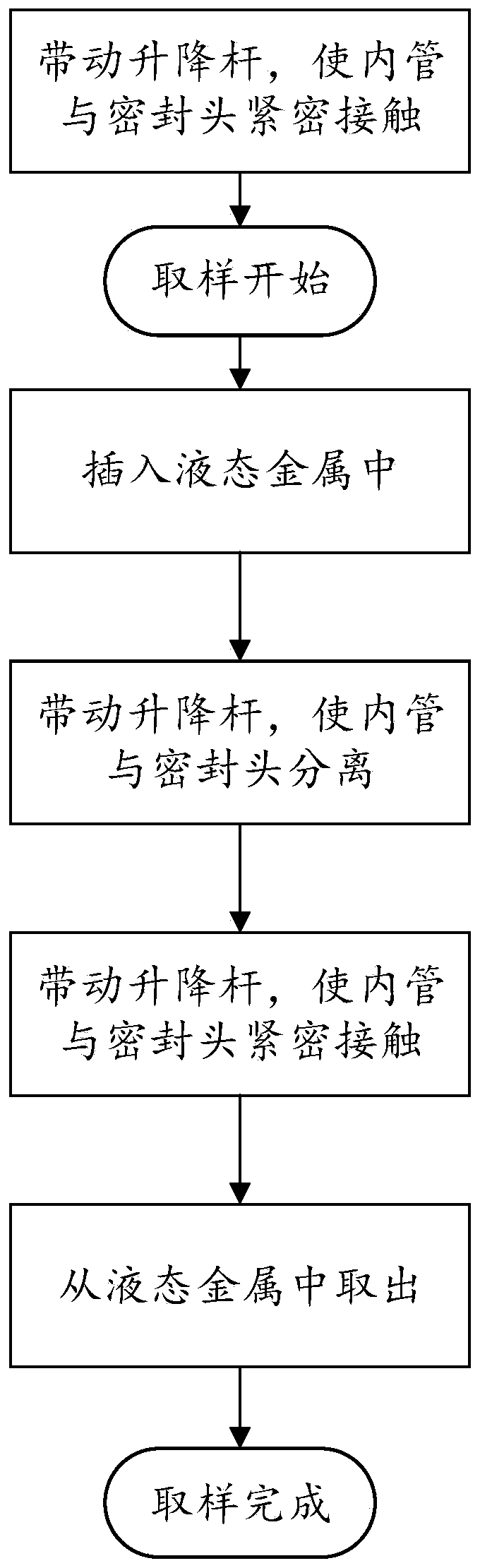

[0033] A liquid metal sampler, comprising an outer tube 1 and an inner tube 2 that are sheathed together, the outer tube 1 is sleeved outside the inner tube 2 and there is a gap between the inner tube 2 and the outer tube 1, and the bottom of the inner tube 2 is provided with The sealing head 5 is provided with a plurality of liquid inlet holes between the sealing head 5 and the outer tube 1 . When the liquid metal sampler of this embodiment takes a sample, the liquid metal enters the inside of the outer tube 1 from the liquid inlet hole. The top of the inner tube 2 is connected with a lifting rod 4, and the lifting rod 4 can drive the inner tube 2 to move up and down inside the outer tube 1. When the lifting rod 4 drives the inner tube 2 to move downward, the inner tube 2 can be in close contact with the sealing head. In addition, both the side wall of the outer tube 1 and the side wall of the inner tube 2 are provided with exhaust holes.

[0034] Before sampling, the inner...

Embodiment 2

[0036] This embodiment 2 is further improved on the basis of embodiment 1. A liquid metal sampler, comprising an outer tube 1 and an inner tube 2 that are sheathed together, the outer tube 1 is sleeved outside the inner tube 2 and there is a gap between the inner tube 2 and the outer tube 1, and the bottom of the inner tube 2 is provided with The sealing head 5 is provided with a plurality of liquid inlet holes between the sealing head 5 and the outer tube 1 . When the liquid metal sampler of this embodiment takes a sample, the liquid metal enters the inside of the outer tube 1 from the liquid inlet hole. The top of the inner tube 2 is connected with a lifting rod 4, and the lifting rod 4 can drive the inner tube 2 to move up and down inside the outer tube 1. When the lifting rod 4 drives the inner tube 2 to move downward, the inner tube 2 can be in close contact with the sealing head. In addition, both the side wall of the outer tube 1 and the side wall of the inner tube 2 ...

Embodiment 3

[0038] Embodiment 3 is further improved on the basis of Embodiment 2. Such as figure 1The liquid metal sampler shown is composed of an outer tube 1, an inner tube 2, a gland 3, a lifting rod 4 and a sealing head 5. The upper end of the outer tube 1 is provided with an external thread and a vent hole, and the upper end of the inner tube 2 is provided with an internal Thread and vent hole, the vent hole at the upper end of the outer tube 1 and the vent hole at the upper end of the inner tube 2 are located at the same horizontal position, which is conducive to the exhaust of the sampler and avoids the existence of air holes in the sample. The vent hole can be a waist-shaped hole to vent A pin is inserted in the hole so that the inner tube can only move up and down but not rotate. Gland 3 is provided with internal threads, the center of the top has a hole, and the diameter of the aperture is larger than the outer diameter of the upper end of lifting rod 4, so that lifting rod 4 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com