Negative pressure dust fall fresh air system for hatchling room

A technology of fresh air system and negative pressure drop, applied in ventilation systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve the problems of insufficient negative pressure value, termination of incubation, extraction, etc., to achieve dust reduction and energy consumption. Low, the effect of optimizing the incubation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

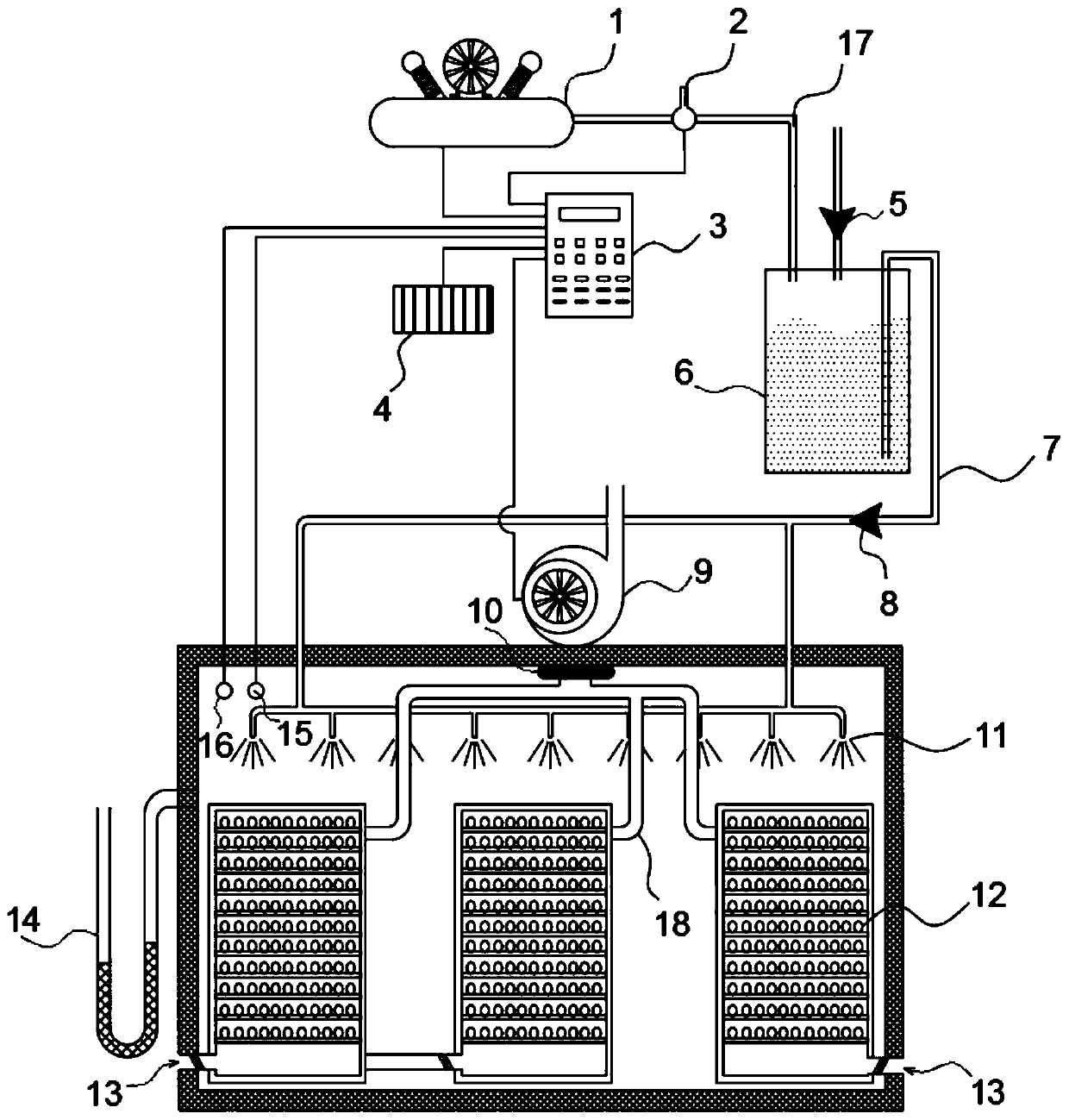

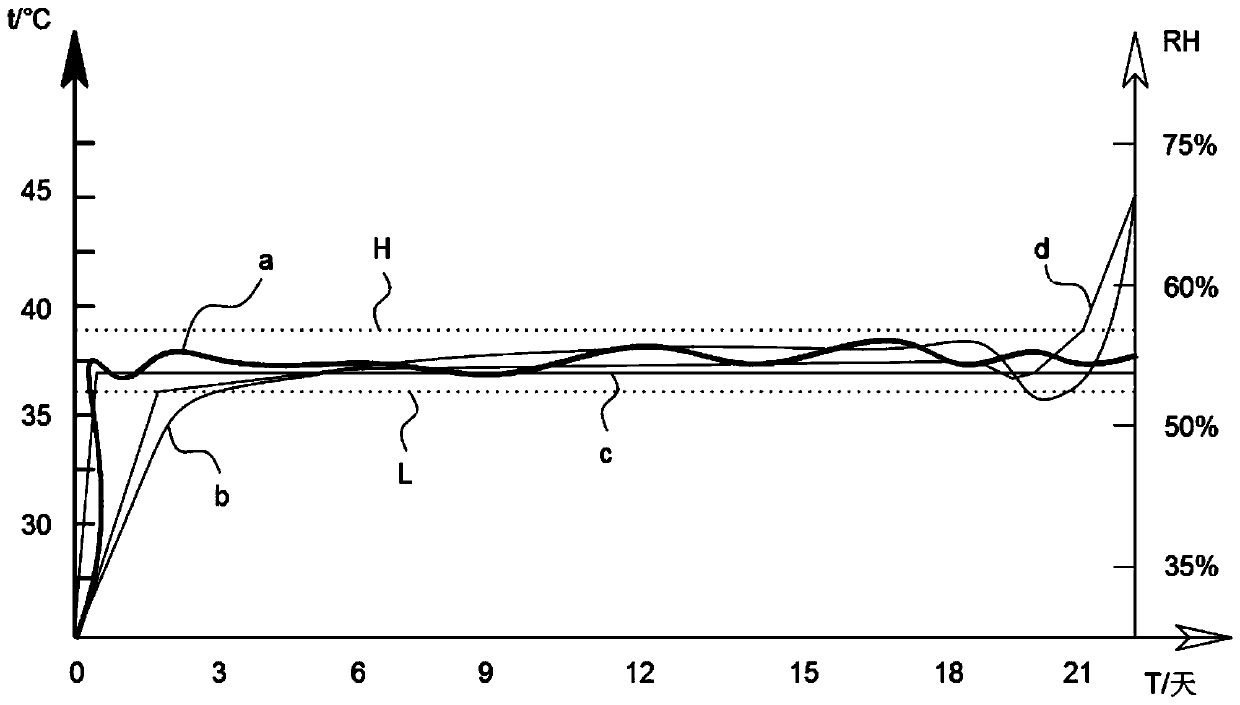

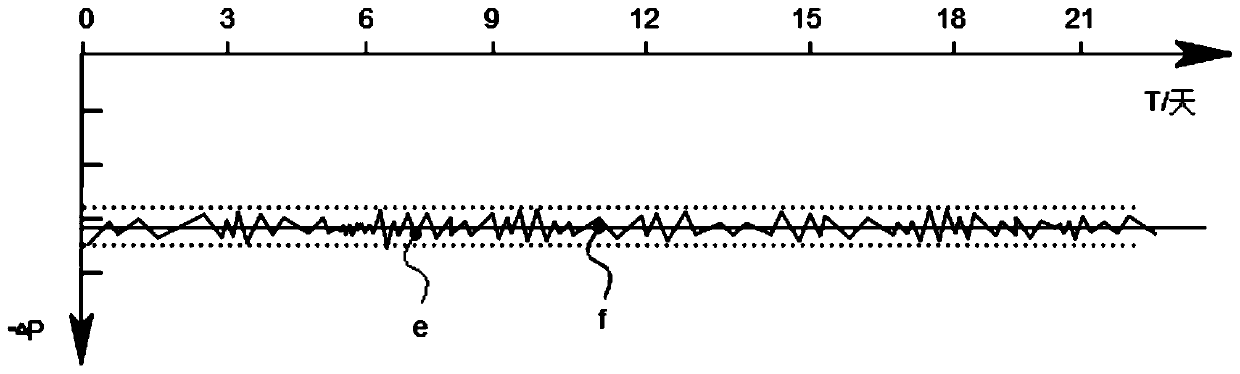

[0033] This embodiment is illustrated by hatching chicks as an example, and the attached figure 1 with 3 A negative pressure dust reduction fresh air system for the hatching room is shown, which includes a dust suppression system for atomizing and spraying the inside of the hatching room and an exhaust system for adjusting the pressure inside the hatching room. Three hatching machines 12 in the brooding room carry out air renewal and keep the exhaust fan 9 of the pressure in the hatching room. In this embodiment, the exhaust fan 9 adopts a centrifugal fan; and the controller 3 that drives and regulates the speed of the exhaust fan 9, The controller 3 is connected with a PLC logic editor 4 for editing and setting the control logic of the controller 3, and is installed in the hatching room for collecting the air pressure in the hatching room and sending it to the controller 3. Sensor 15; the exhaust passages of any one hatcher 12 are all communicated with each other through the...

Embodiment 2

[0038] In order to better reflect the beneficial effects of the present invention relative to the prior art, on the basis of Example 1, further in combination with the description attached Figure 4-6 As shown, the flow diversion guide 10 has a flow channel wall 102 as the main air flow channel, and the flow channel wall 102 is provided with a plurality of guide vanes 101 inclined in the upper direction, and the guide vanes 101 and the flow channel wall The angle between the sides of 102 close to the air inlet end 105 is an acute angle. In this embodiment, the included angle between the deflector 101 and the side of the flow channel wall 102 close to the air inlet end 105 is 25°-45°. The above-mentioned setting of this embodiment needs to be emphatically emphasized and explained, and the above-mentioned structure is also one of the important improvement points of the applicant. Based on the fact that the hatcher 12 will include two states of ventilation and heat preservation ...

Embodiment 3

[0042] On the basis of any of the above-mentioned embodiments, in conjunction with the description Figure 1-6 As shown, the dust suppression system includes a spray pipe 7 installed inside and outside the hatching room, and a plurality of free ends of the spray pipe 7 located in the hatching room are air-tightly connected to spray water for atomizing the spraying water. The spray head 11, the other end of the spray pipe 7 communicates with the bottom of the spray water tank 6 which is airtightly arranged, and the top of the spray water tank 6 communicates with a water supply pipe and an air supply pipe 17 respectively, and the air supply pipe 17 communicates with the air supply pipe 17 controlled by the The supercharger 1 controlled by the controller 3 is connected to the air supply pipe 17 between the supercharger 1 and the spray water tank 6, and the electromagnetic valve 2 controlled by the controller 3 is installed on it. One end of the spray pipe 7 close to the spray tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com