A construction method of an energy-dissipating and shock-absorbing composite shed-cave structure that resists the impact of landslides and collapses

A construction method and shed hole technology, which can be used in construction, protective equipment and other directions, can solve the problems of plastic damage of steel wire grilles and polystyrene foam, high maintenance costs, and achieve good buffering effect, low cost, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and preferred example, energy-dissipating shock-absorbing combined structure and construction method of the present invention are described in detail as follows:

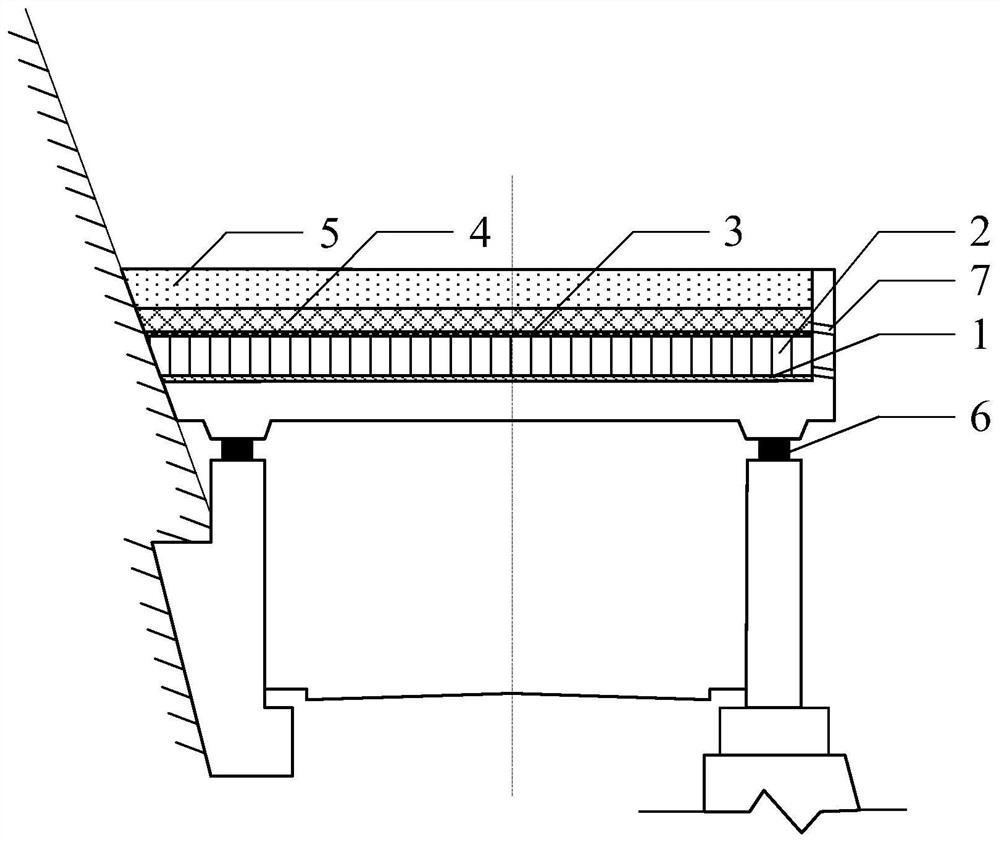

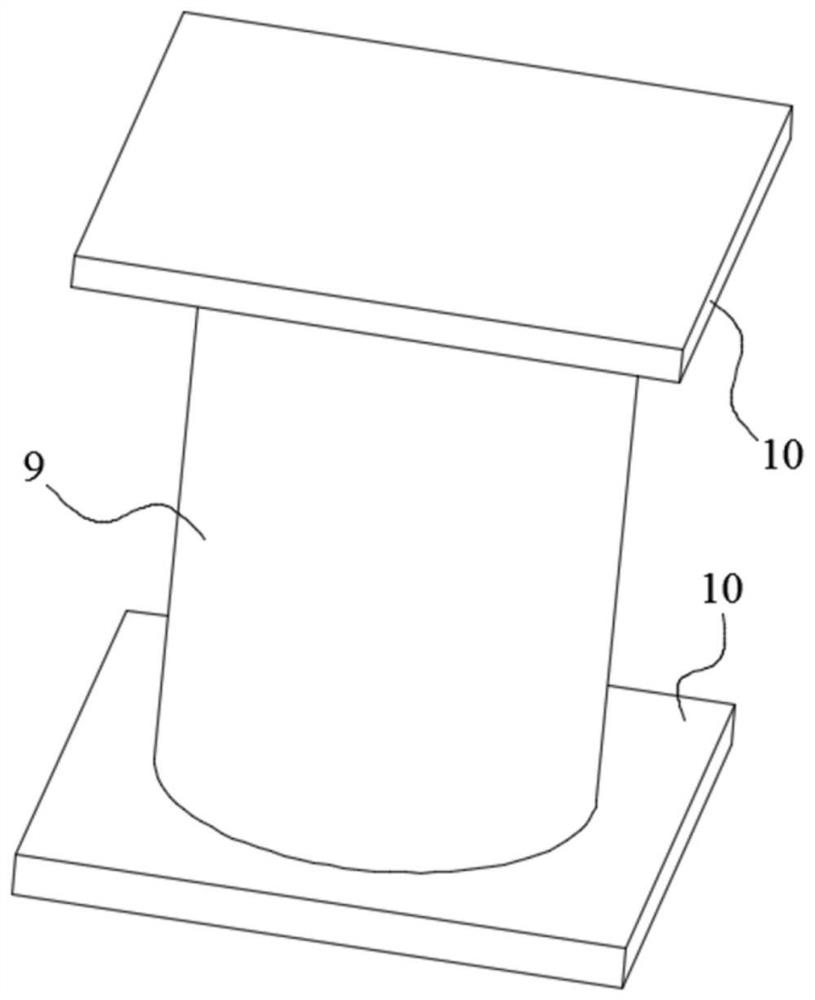

[0030] like Figure 1-Figure 3 As shown, it is a specific structure of an energy-dissipating and shock-absorbing combined shed-cavity structure for resisting the impact of landslides and collapses, including roof beams, shed-hole plates, composite buffer cushions and energy-dissipating shock absorbers. On both sides of the ground in the area (that is, the side close to the mountain and the side away from the mountain), the shed hole plate is supported on the top of the roof beam through energy dissipation shock absorbers to form a shed hole structure that resists the impact of landslides and collapses. The composite buffer cushion layer includes a foam cushion layer 2, a steel plate layer 3, a geocell 4 and a soil layer 5, which are successively laid on the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com