Operation hanging basket for bolted connection of reinforced concrete composite beam sections based on bridge girder erection machine

A technology for steel-concrete composite beams and bridge erecting machines, which is applied to the field of operating hanging baskets, can solve problems such as obstruction of walking, influence on permanent structure force, influence on connection quality, etc., and achieves the effect of ensuring connection rigidity, easy maintenance, and increasing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

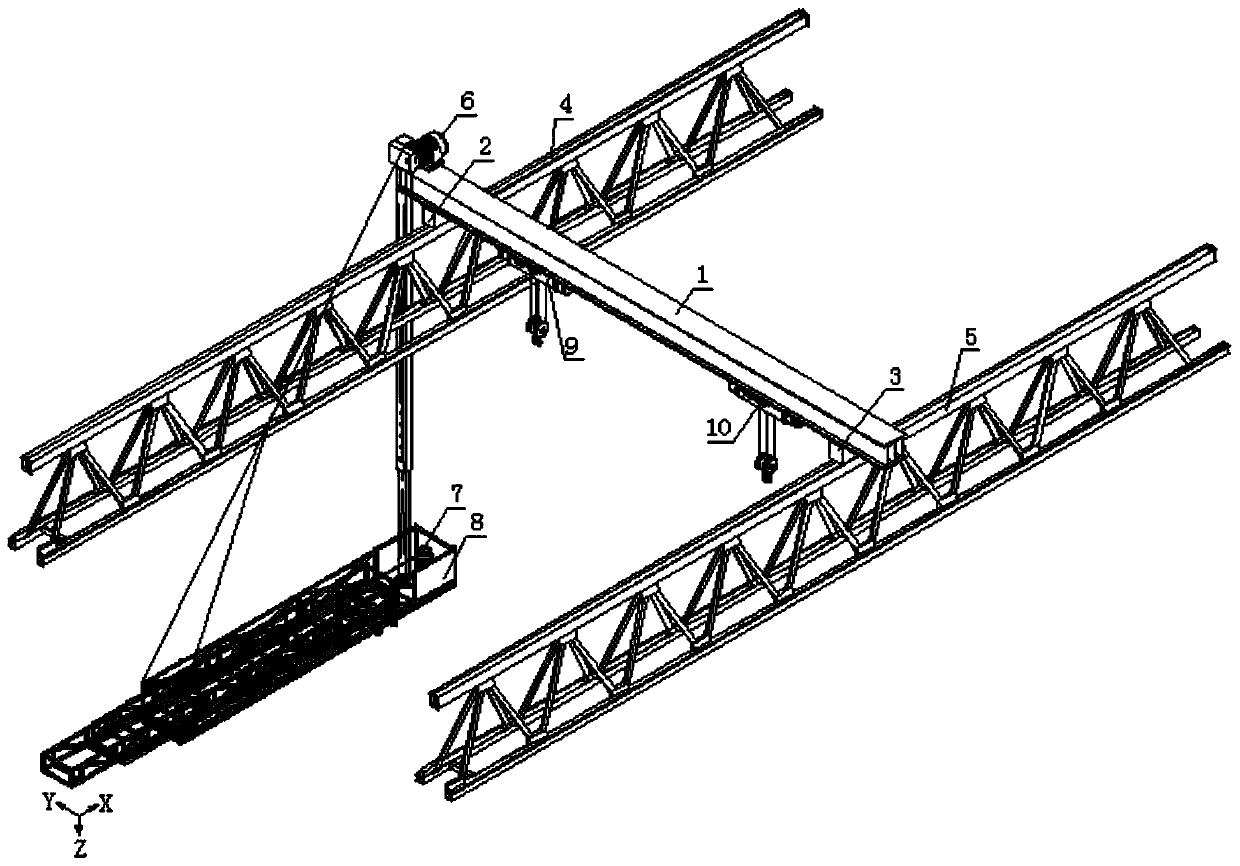

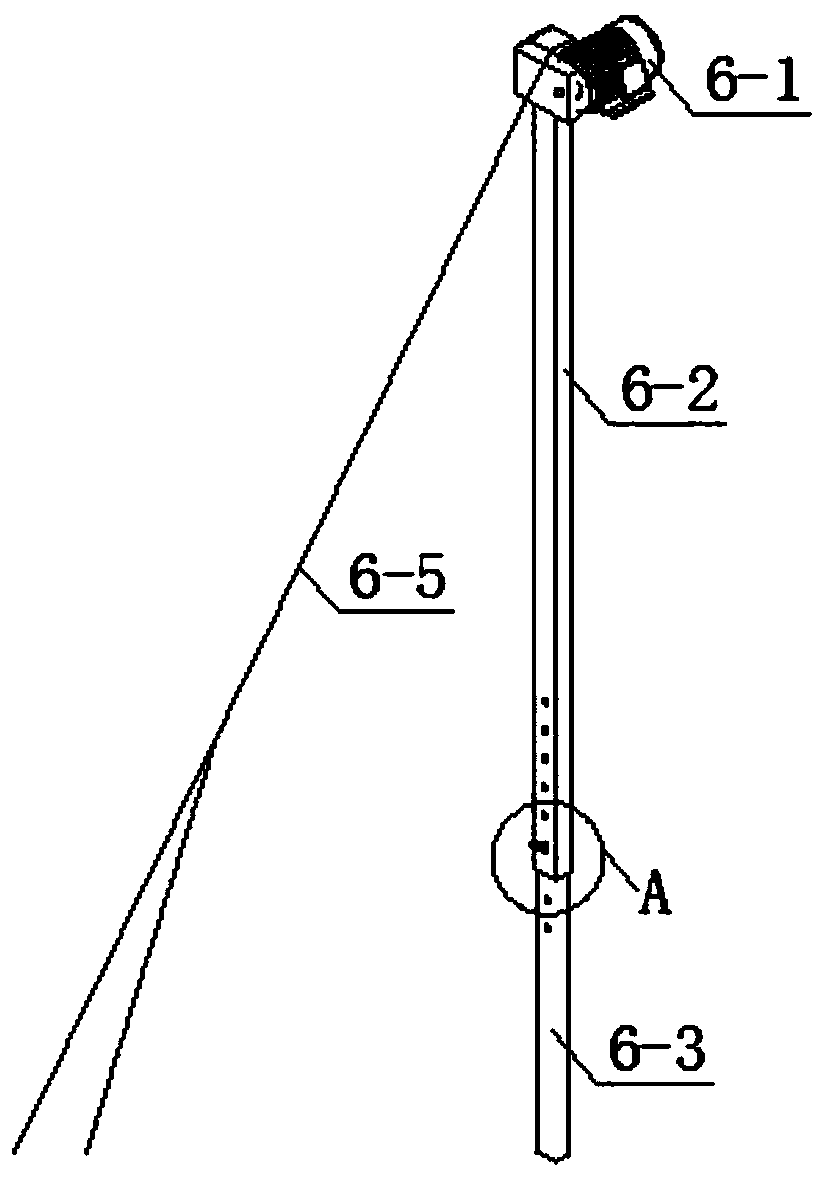

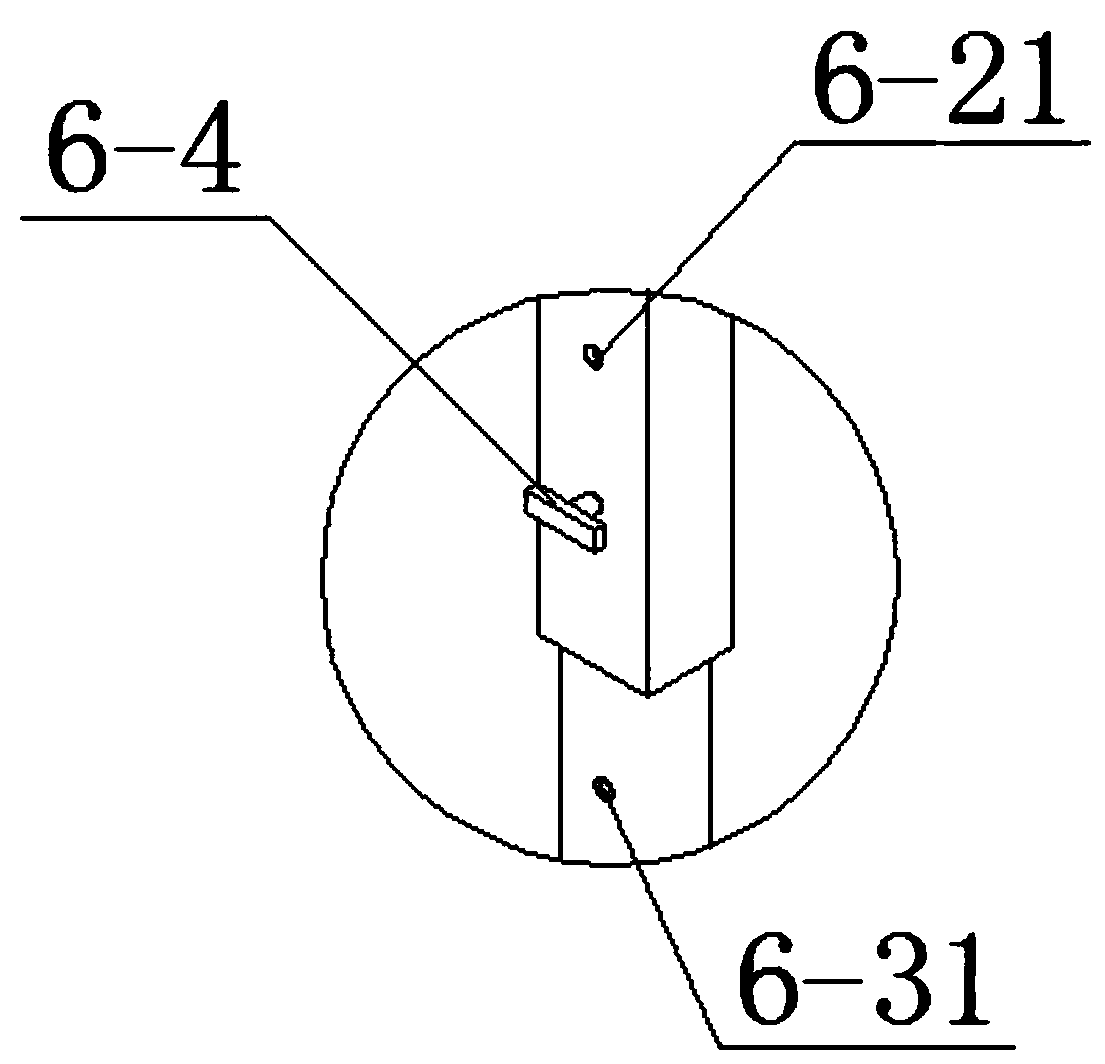

[0057] see figure 1 As shown, the present invention provides an operation basket based on the bolt connection of steel-concrete composite girder sections of bridge erecting machines, including a main girder 1, a first traveling trolley 2, a second traveling trolley 3, a lifting device 6, and a steering device 7. The operating platform 8, the first lifting device 9 and the second lifting device 10, the main girder 1 passes through the first traveling trolley 2, the second traveling trolley 3 and the double guide beam 4 of the left bridge machine, the right bridge machine The double guide beams 5 are connected, the lifting device 6 is fixedly installed on the main beam 1, the steering device 7 is connected with the lifting device 6, the operating platform 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com