Steel beam and composite beam connecting structure

A technology for connecting structures and composite beams, applied in bridges, bridge forms, buildings, etc., can solve the problems of high prefabrication precision requirements, complicated connection methods and cumbersome processes, and achieve simple structure, smooth force transmission, and strong bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

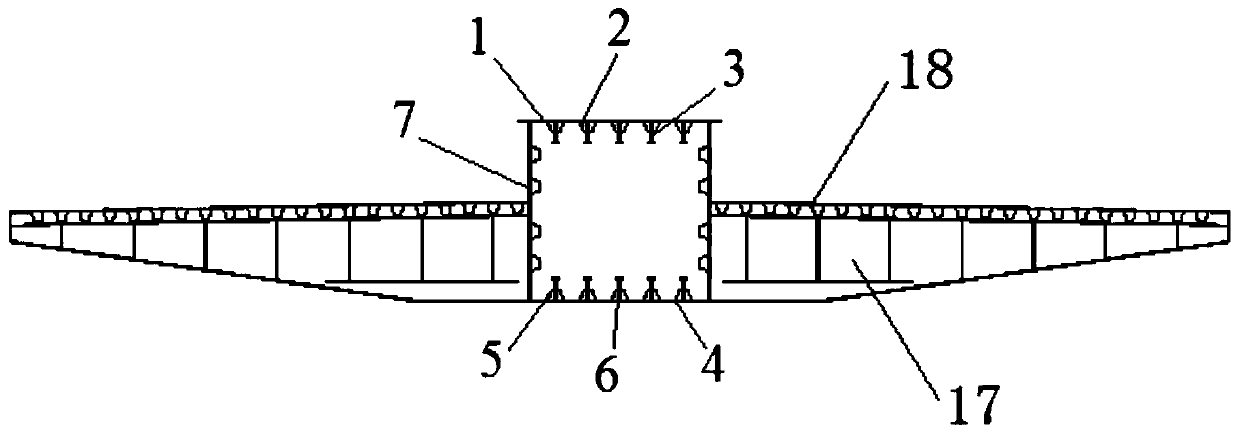

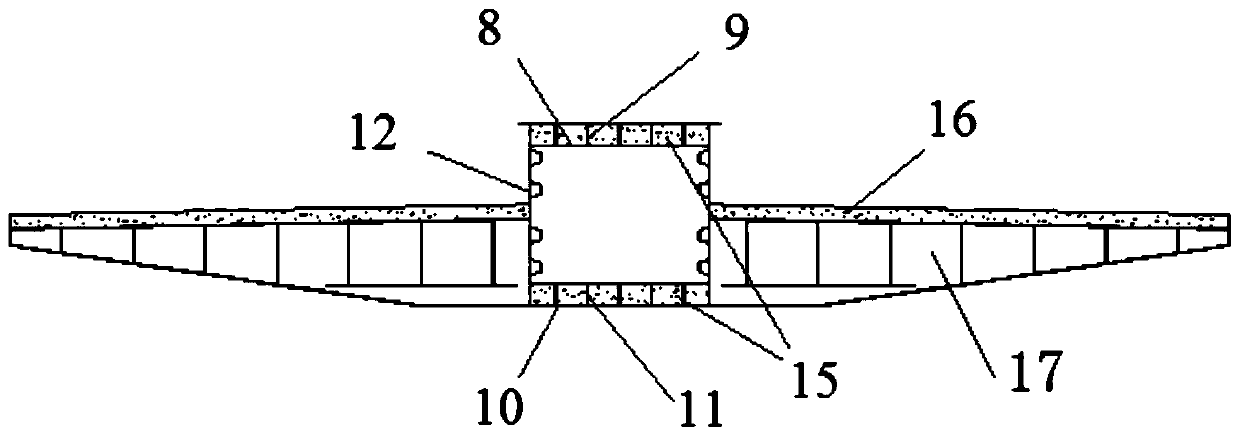

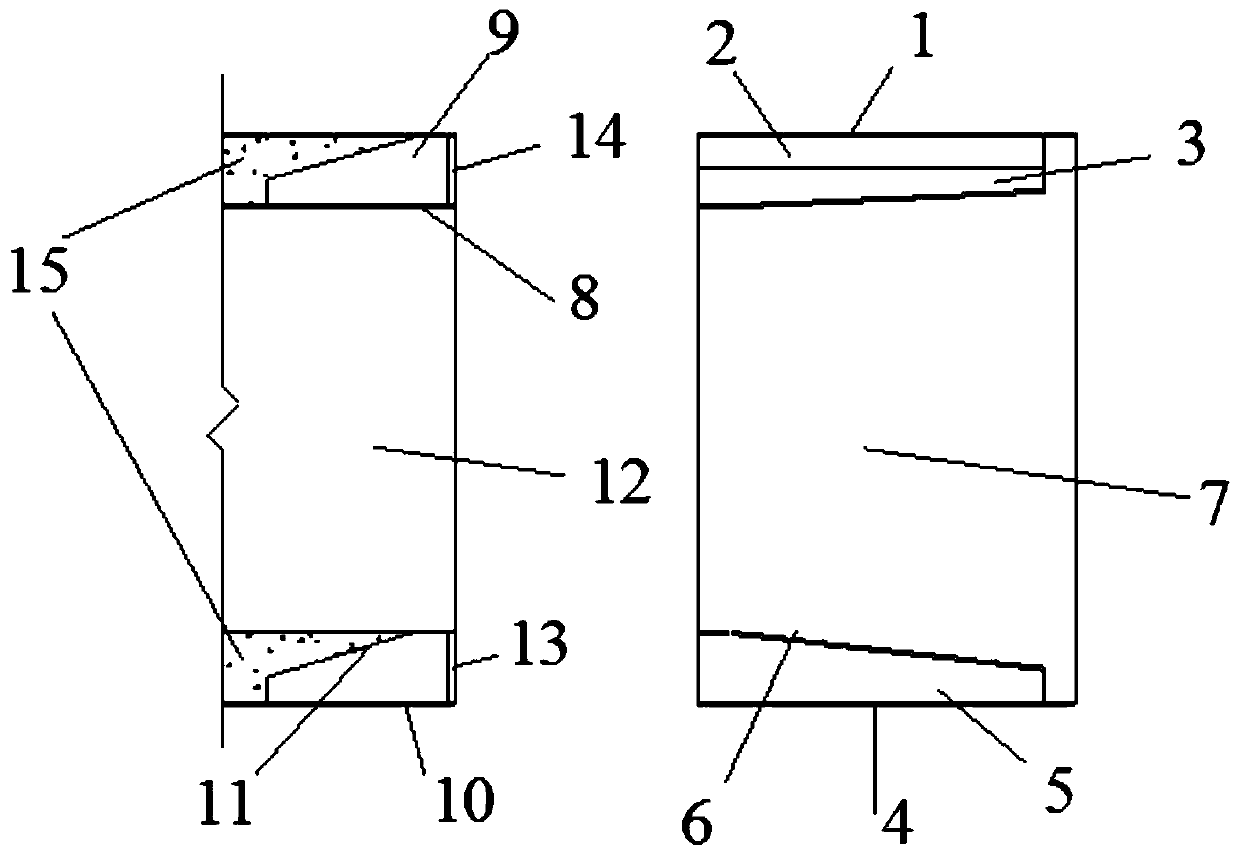

[0039] refer to figure 1 , figure 2 , image 3 , the present embodiment provides a connection structure of a steel beam and a composite beam, including a connected steel box girder and a composite beam.

[0040] In this embodiment, the steel box girder includes a central steel box girder main longitudinal beam and steel box girder cantilever plates connected to both sides of the steel box girder main longitudinal beam, and the steel box girder main longitudinal beam includes a steel beam top plate 1, a steel beam bottom plate 4 and The steel beam web 7 , the steel beam top plate 1 and the steel beam bottom plate 4 are respectively connected to the upper and lower ends of the steel beam web 7 , and the steel box girder cantilever plate is connected to the steel beam web 7 .

[0041]In this embodiment, the composite beam includes a composite beam main longitudinal beam in the center and composite beam cantilever plates connected on both sides of the composite beam main longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com