Calamus sugar polymer and its preparation method and application

A technology of polymers and calamus sugar, which is applied in the field of medicine, can solve the problems of prevention and treatment of neurodegenerative diseases that have not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The extraction method of embodiment 1 calamus glycopolymer

[0057] 1) Material selection: select the dried rhizome of Acorus calamus, cut into small sections, soak in water for 6-12 hours;

[0058] 2) Water extraction: Extract the rhizome of Acorus calamus soaked in step 1) with 10 times the volume of hot water (80° C.) for 4 times, 3 hours each time, collect the extract, and dry the medicinal residues;

[0059] 3) Fractional alcohol precipitation: the extract obtained in step 2) was concentrated under reduced pressure at 60° C., and ethanol was added for alcohol precipitation, so that the volume concentration of ethanol was 50%, and left standing at room temperature for 24 hours, divided into supernatant 1 and precipitation 1, Collect the precipitate 1 to obtain the crude sugar polymer AT1; Concentrate the supernatant 1 again under reduced pressure at 60°C, add ethanol for alcohol precipitation, so that the volume concentration of ethanol is 70%, let it stand at room ...

Embodiment 2

[0062] The extraction and separation method of embodiment 2 Acorus calamus sugar polymer AT1-3

[0063] 1) Material selection: select the dried rhizome of Acorus calamus, cut into small sections, soak in water for 6-12 hours;

[0064] 2) Water extraction: Extract the rhizome of Acorus calamus soaked in step 1) with 10 times the volume of hot water (80° C.) for 4 times, 3 hours each time, collect the extract, and dry the medicinal residues;

[0065] 3) Fractional alcohol precipitation: Concentrate the extract obtained in step 2) at 60°C under reduced pressure, add ethanol to make the volume concentration of ethanol 50%, let stand at room temperature for 24h, divide into supernatant 1 and precipitate 1, collect the precipitate and Raw sugar polymer AT1 was obtained;

[0066] 4) Purification: the crude sugar polymer AT1 was deproteinized by the Sevag method, and after the deproteinization, the crude sugar polymer was dialyzed with a dialysis bag (molecular weight cut-off of 1000...

Embodiment 3

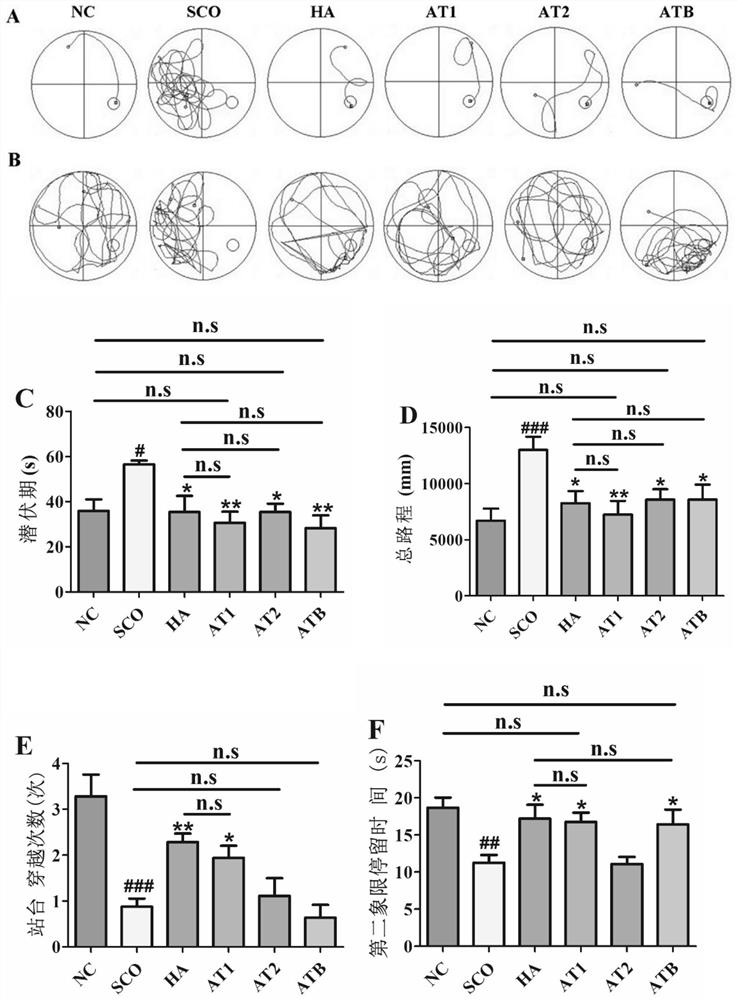

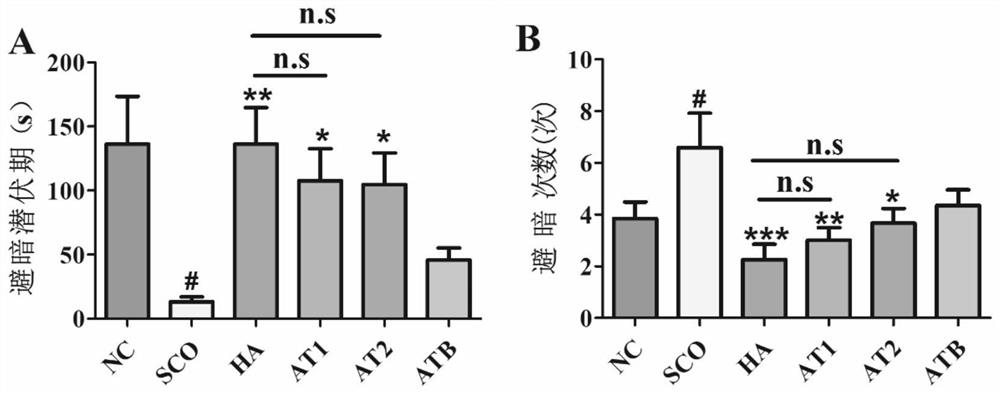

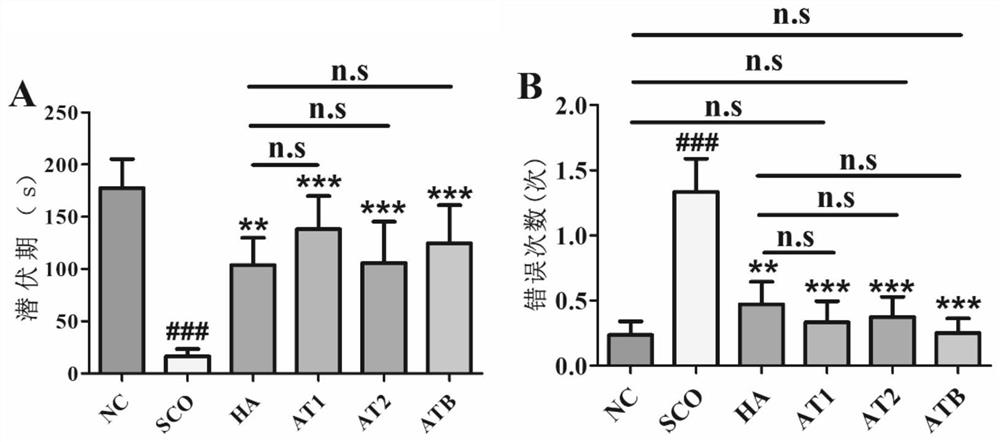

[0105] Example 3 Study on Anti-Alzheimer's Disease Activity of Acorus Calamus Raw Sugar Polymers AT1, AT2, and ATB

[0106] 1. Experimental method

[0107] 1.1 Experimental design and grouping:

[0108] A total of 120 male KM mice aged 6 weeks in SPF grade were randomly divided into 6 groups, 20 in each group. Each group was administered separately: normal group NC: normal saline; model group SCO: normal saline; positive control group HA: huperzine A (2 mg / kg); AT1 group: calamus glycopolymer AT1 (500 mg / kg); AT2 group: Acorus glycopolymer AT2 (500 mg / kg); ATB group: Acorus glycopolymer ATB (500 mg / kg). After intragastric administration for 30 minutes every day, the normal group was intraperitoneally injected with normal saline, and the other groups were intraperitoneally injected with scopolamine (1mg / kg, injection volume: 0.1mL / 10g) to establish models. Weigh once every two days, adjust the dosage according to the change of body weight, and gavage continuously for 14 days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com