Wind stopping device for ship hull flat steel structure welding

A flat steel and hull technology, applied in the field of hull flat steel structure welding, can solve the problems of time-consuming and laborious, low welding efficiency, and long working hours of hull flat steel welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

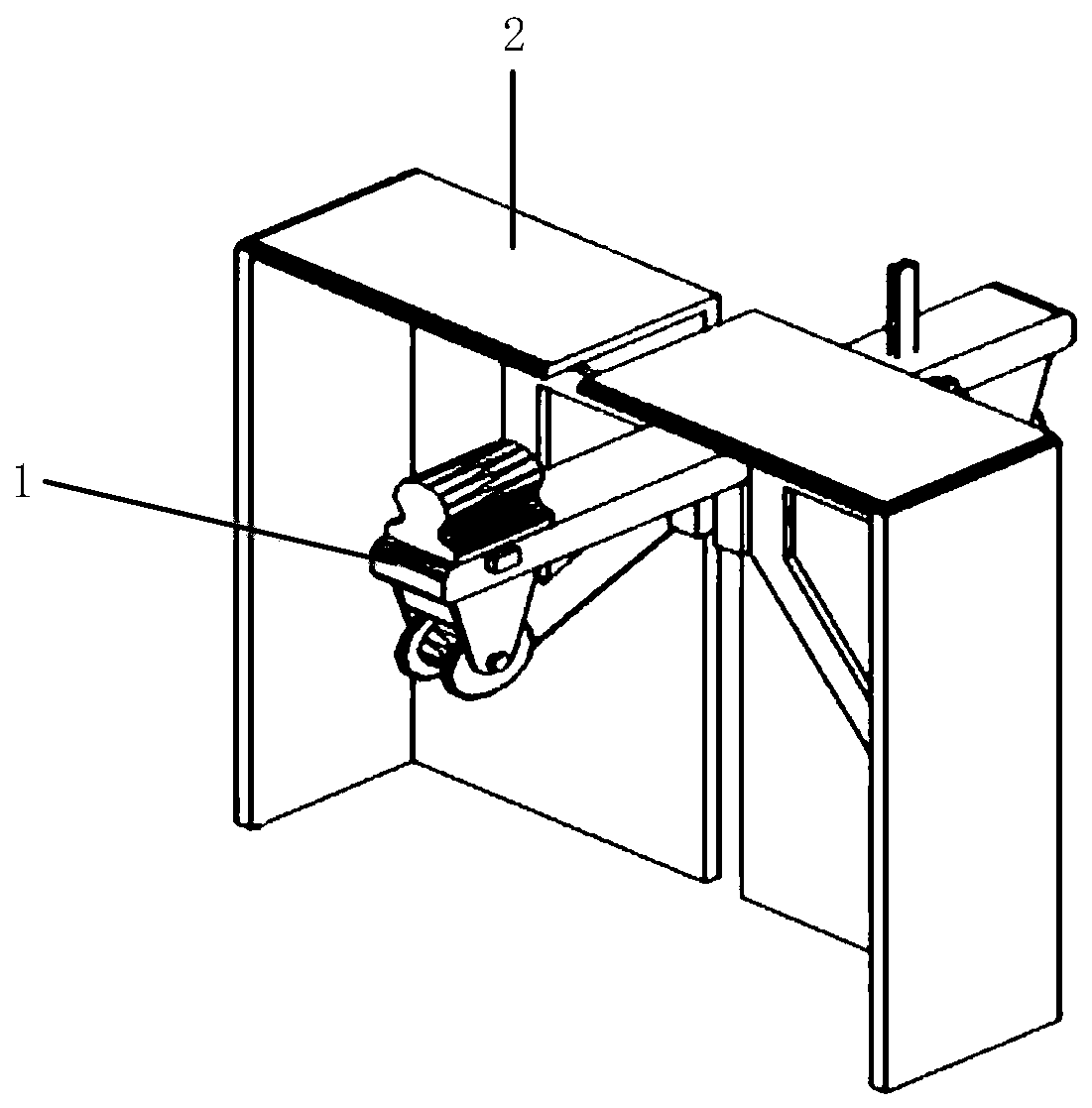

[0045] refer to figure 1 , a windshield device for welding flat steel structures of hulls, comprising a power unit 1 and a windshield plate 2 .

[0046] The power unit 1 is fixedly connected with the windproof plate 2;

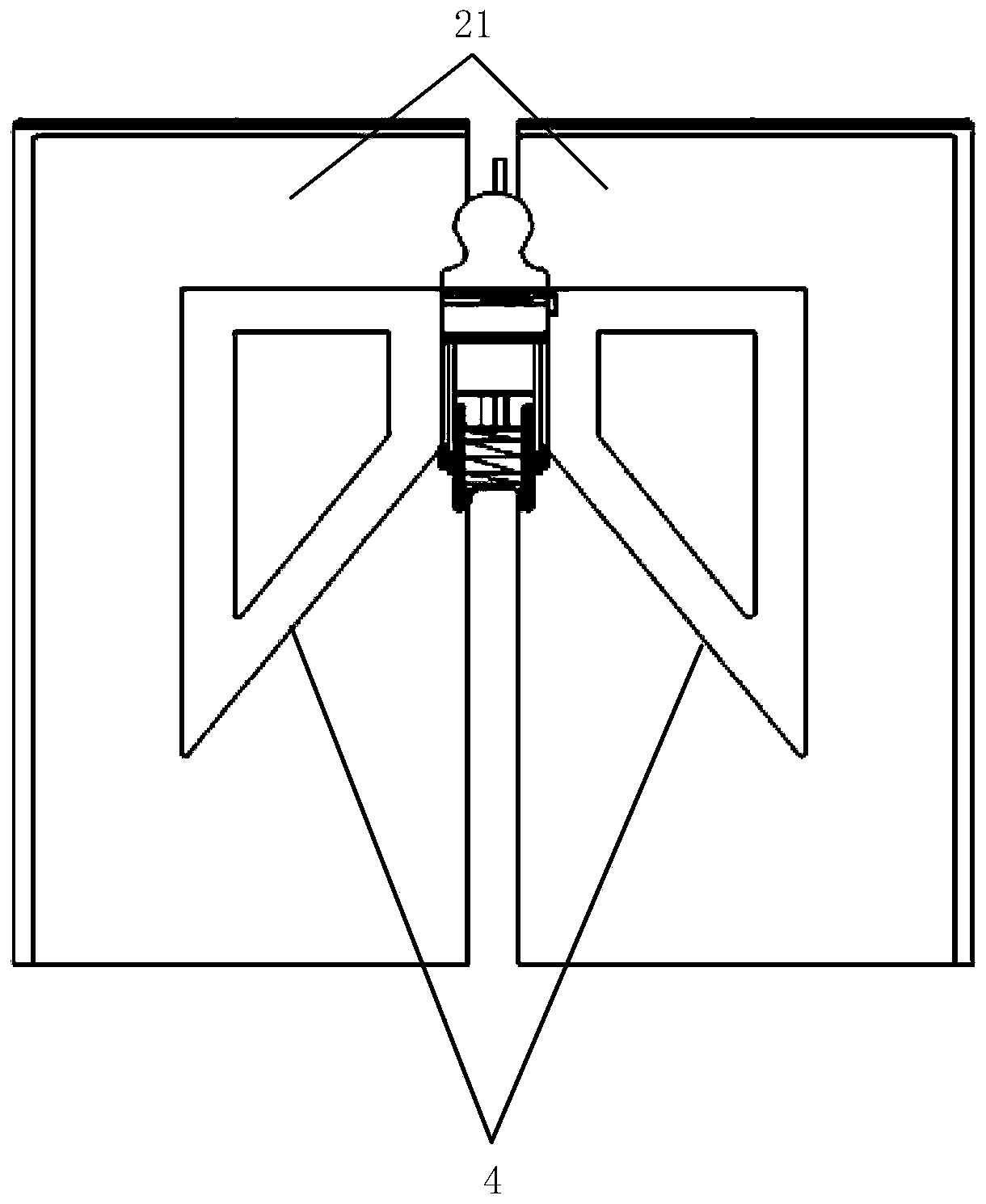

[0047] The windproof plate 2 includes an opening, and when the flat steel structure of the hull is welded, the windproof plate 2 bridges the flat steel structure through the opening;

[0048] The power device 1 is used to drive the windproof plate 2 to move along the direction in which the flat steel structure extends.

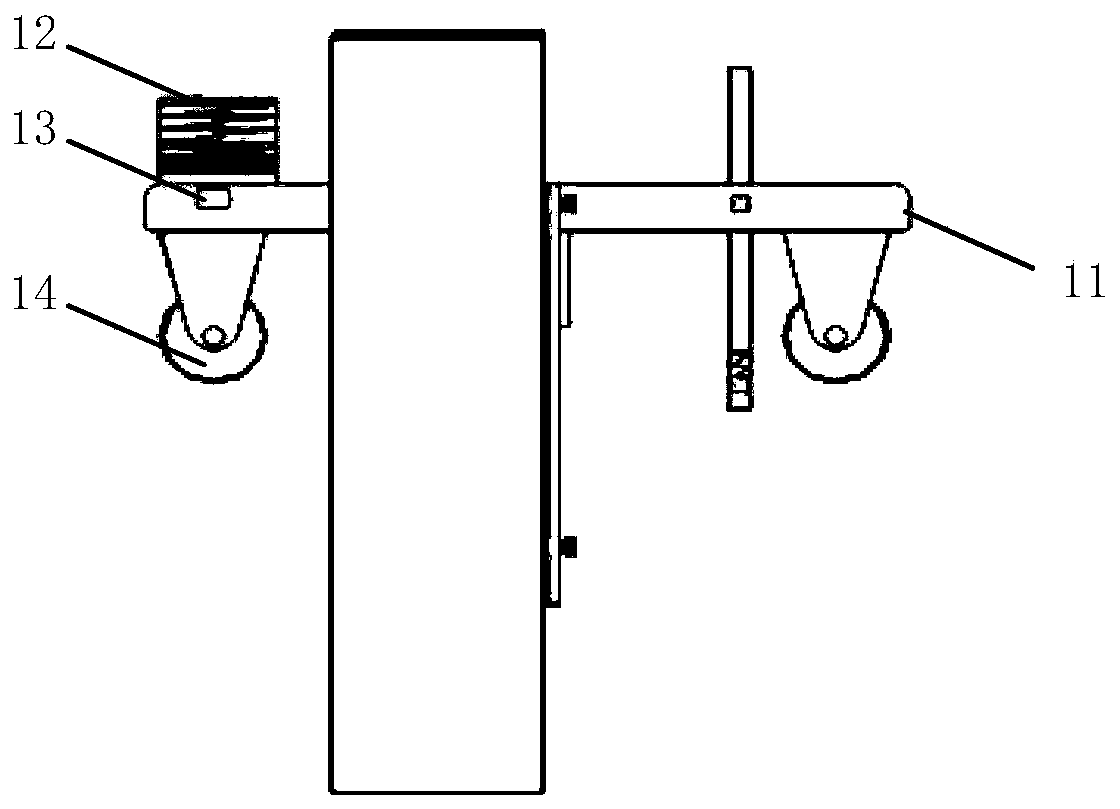

[0049] refer to figure 2 , the power unit 1 includes a trolley body 11, a power transmission module 12, a start speed regulating controller 13 and at least two rollers 14;

[0050] The power transmission module 12 and the start speed regulating controller 13 are fixed on the trolley body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com