Vehicle multi-dimensional force sensor decoupling method based on PSO optimized LSSVM

A multi-dimensional force sensor and sensor technology, which is applied in the direction of instruments, measuring force components, force/torque/power measuring instrument calibration/testing, etc., can solve problems affecting sensor measurement accuracy, local optimal solution, and low numerical accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

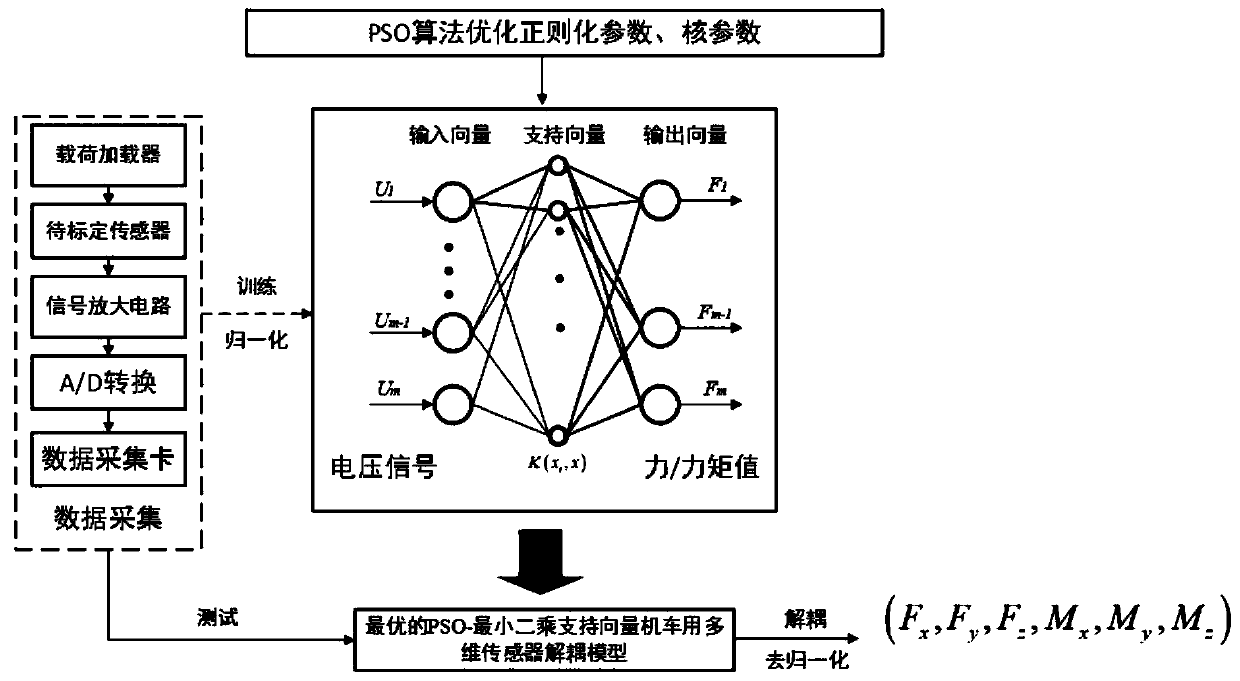

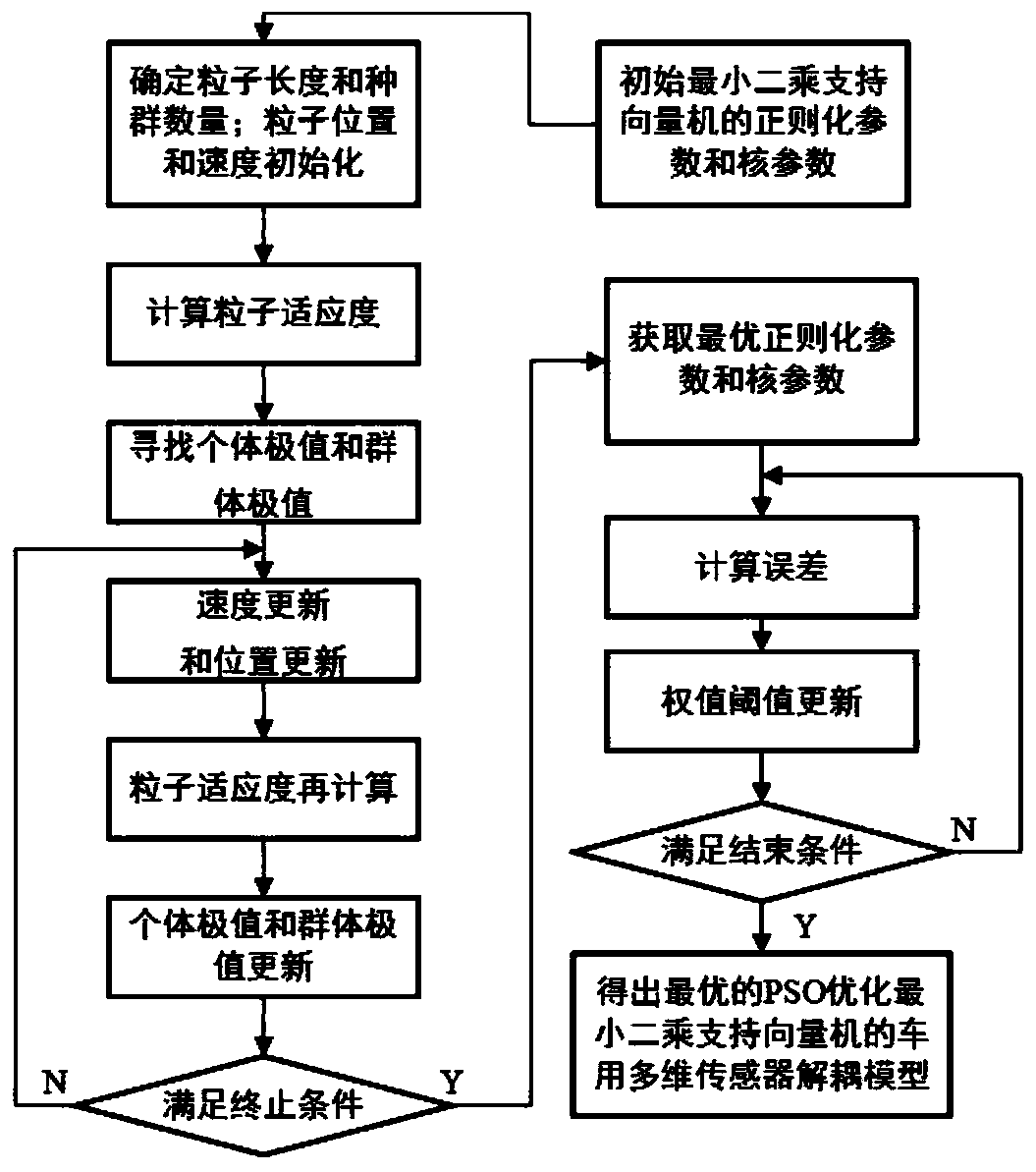

[0043] The present invention provides a vehicle multi-dimensional force sensor decoupling method based on PSO optimized LSSVM, establishes a least squares support vector machine decoupling model, and uses PSO (particle swarm algorithm) to globally search for optimal characteristics to optimize the least squares support vector machine parameters, so that the least square support vector machine decoupling model has good convergence and adaptability, so that the multi-dimensional force sensor has better measurement accuracy, so as to meet the actual application requirements.

[0044] As an embodiment of the present invention, a schematic diagram of a decoupling method for calibration and decoupling of a vehicle multi-dimensional force sensor based on a PSO-optimized least squares support vector machine, figure 2 A schematic diagram of the training...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com