Motor torque ripple test bench and test method

A technology of test and motor torque, which is applied in the direction of motor generator test, torque measurement, measuring device, etc. It can solve the problems of narrow test range, large error, and inability to change the torsion bar stiffness in a large range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This example takes a 3.6kW permanent magnet synchronous motor as an example to illustrate the establishment and testing process of the torque ripple test system.

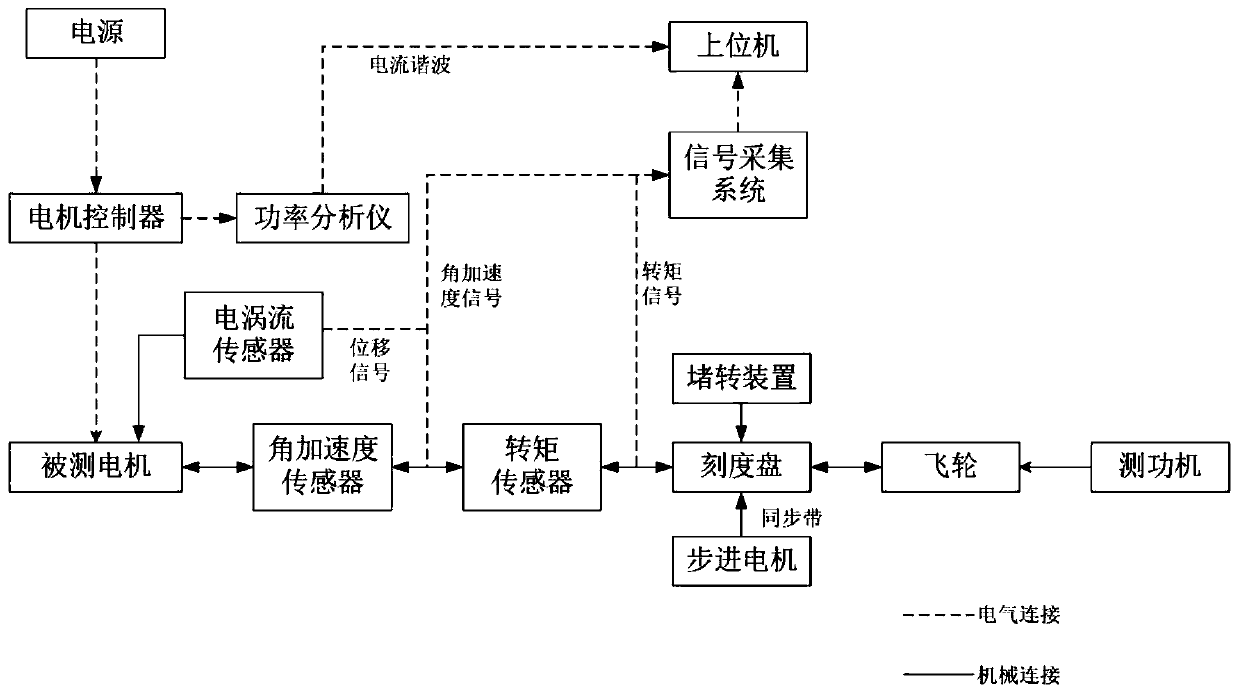

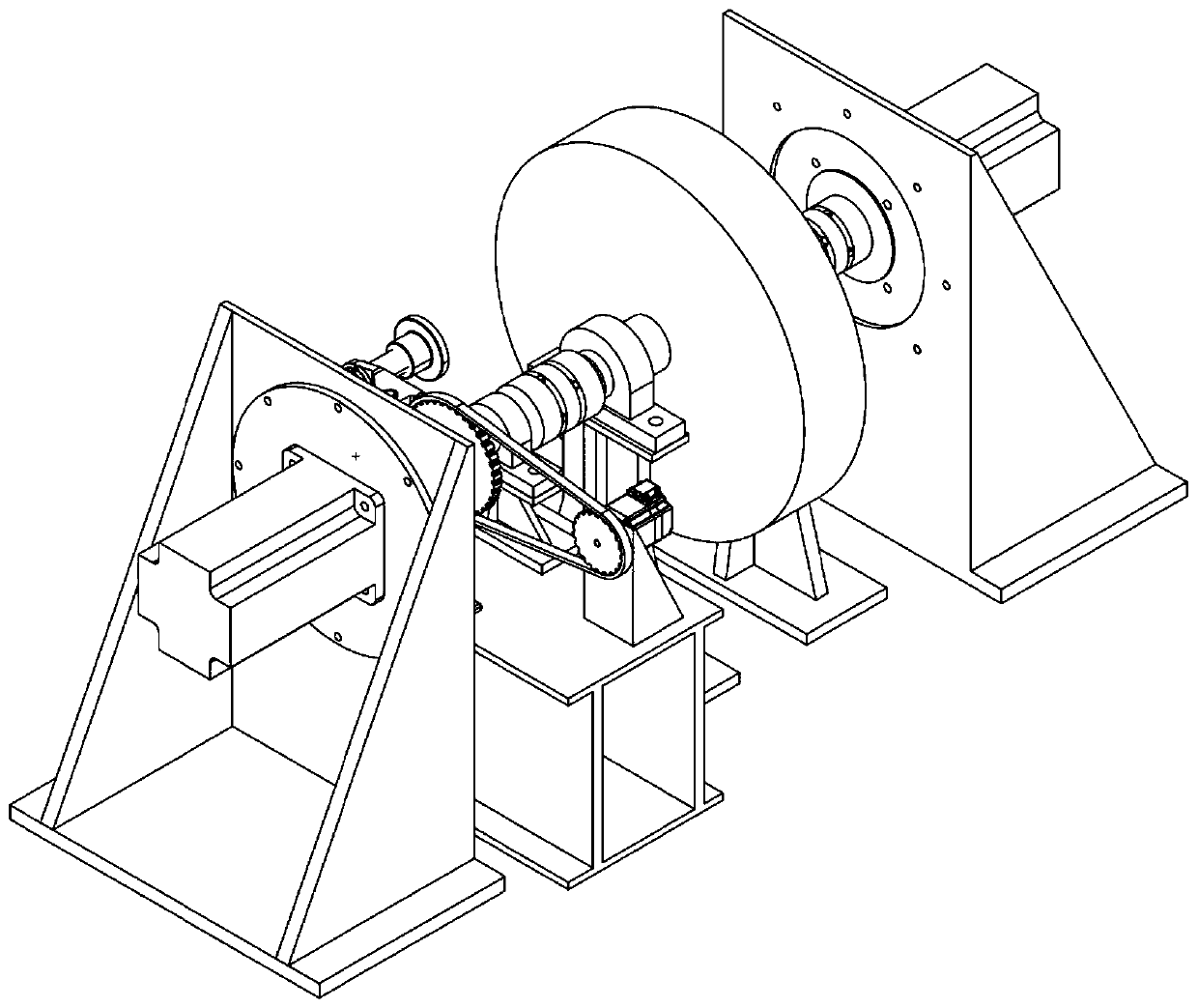

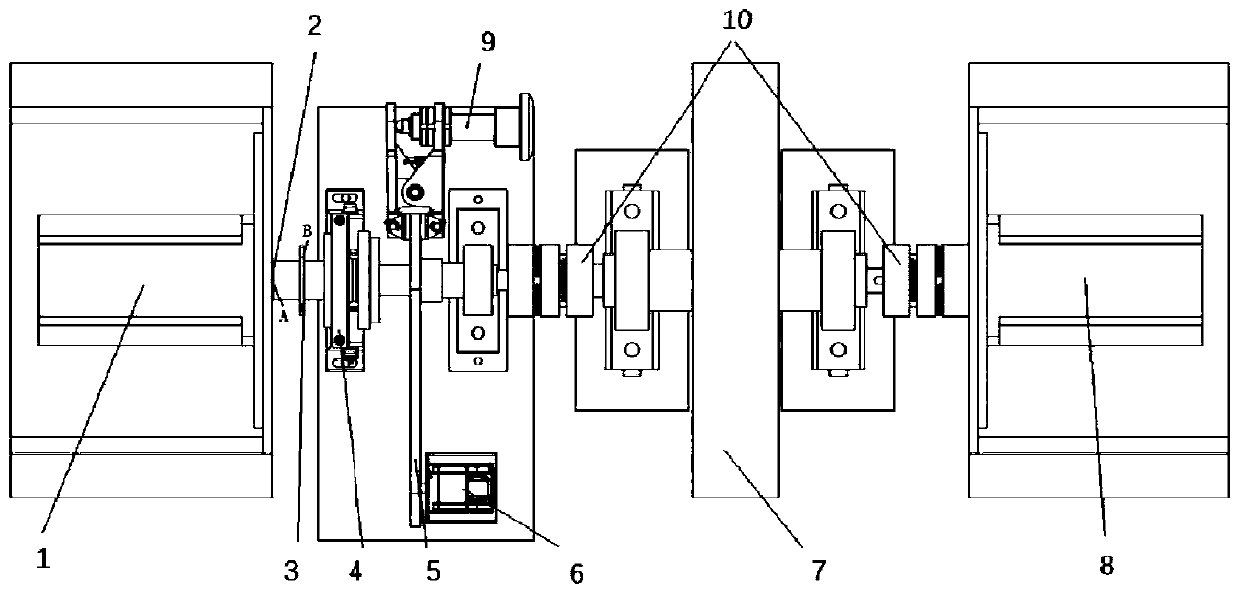

[0034] to combine Figure 1-3 As shown, a kind of motor torque ripple test bench of the present invention comprises: motor controller, power supply, power analyzer, host computer, signal acquisition system, tested motor 1, eddy current displacement sensor 2, angular acceleration sensor 3. Torque sensor 4, synchronous belt transmission structure 5, stepping motor 6, elastic coupling, flywheel 7, dynamometer 8, brake 9 and elastic coupling 10.

[0035] The motor 1 under test includes a rotor shaft A;

[0036] The synchronous belt transmission structure includes a large pulley, a small pulley and a synchronous belt, and the synchronous belt transmission connects the large pulley and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com