Side suction-type range hood and gap adjusting method thereof

A range hood and gap adjustment technology, applied in the field of gap adjustment and side-suction range hoods, can solve the problems of poor appearance, inability to open panels, and large side gaps between panels and smoke shields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

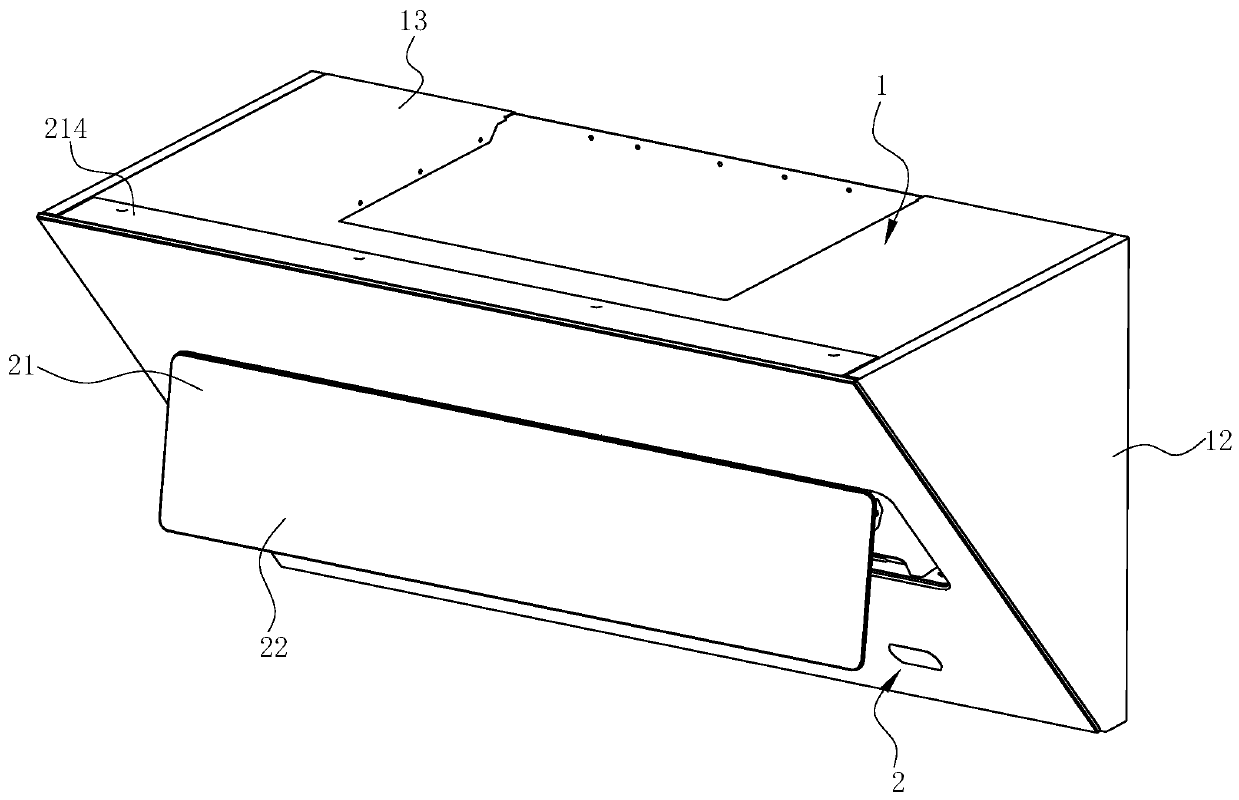

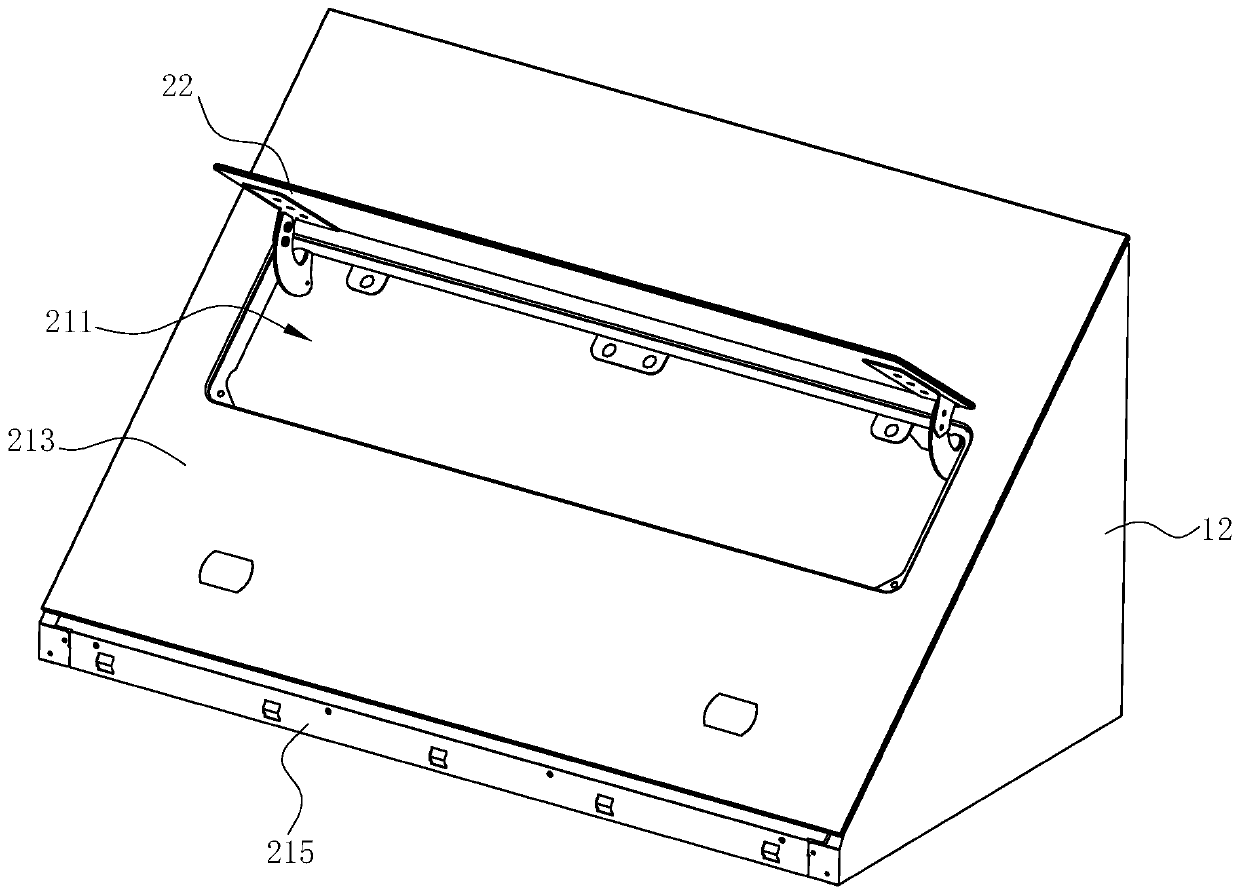

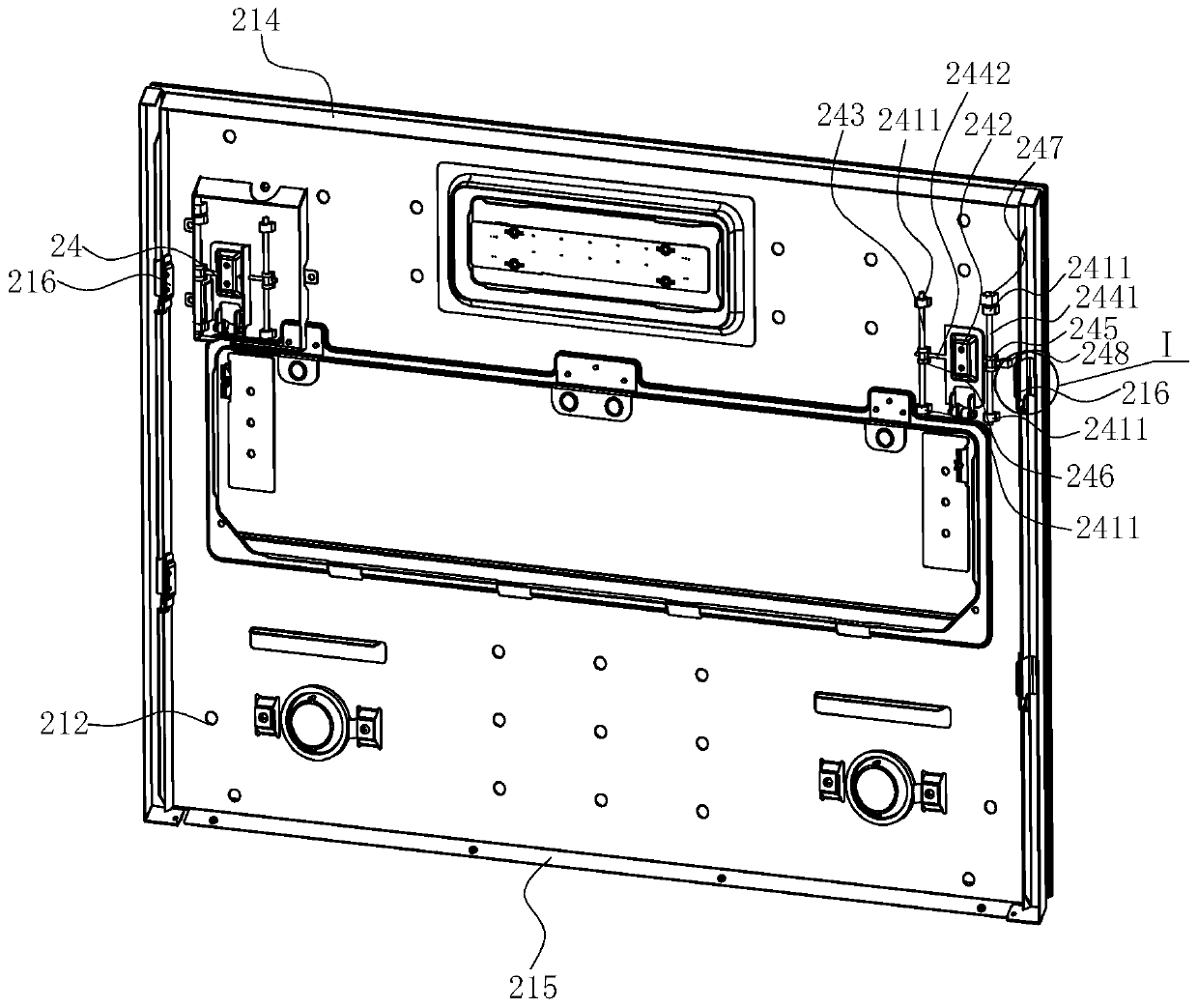

[0051] see Figure 1 to Figure 10 , a side suction range hood comprising a housing 1 and a panel assembly 2 arranged on the front side of the housing 1 . For ease of description, "front", "rear", "left", and "right" in this specification refer to the direction of the user of the range hood relative to the user.

[0052] The housing 1 comprises a left side plate 11, a right side plate 12, and a top rear plate 13 arranged between the left side plate 11 and the right side plate 12, and the front faces of the left side plate 11 and the right side plate 12 are all from top to The bottom is gradually inclined backward. In this embodiment, the left side plate 11 and the right side plate 12 are both triangular.

[0053] The panel assembly 2 includes a panel 21 and a smoke baffle 22 arranged on the panel 21 . The panel 21 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com