Suspended single rotor gas flow meter

A gas flow meter, single rotor technology, applied in fixed measurement chambers and other directions, can solve the problems of rotor not fixed, rotor opening and positioning baffle friction, rotor sinking, etc., to improve service life and accuracy, reduce Effects of pressure loss and frictional resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

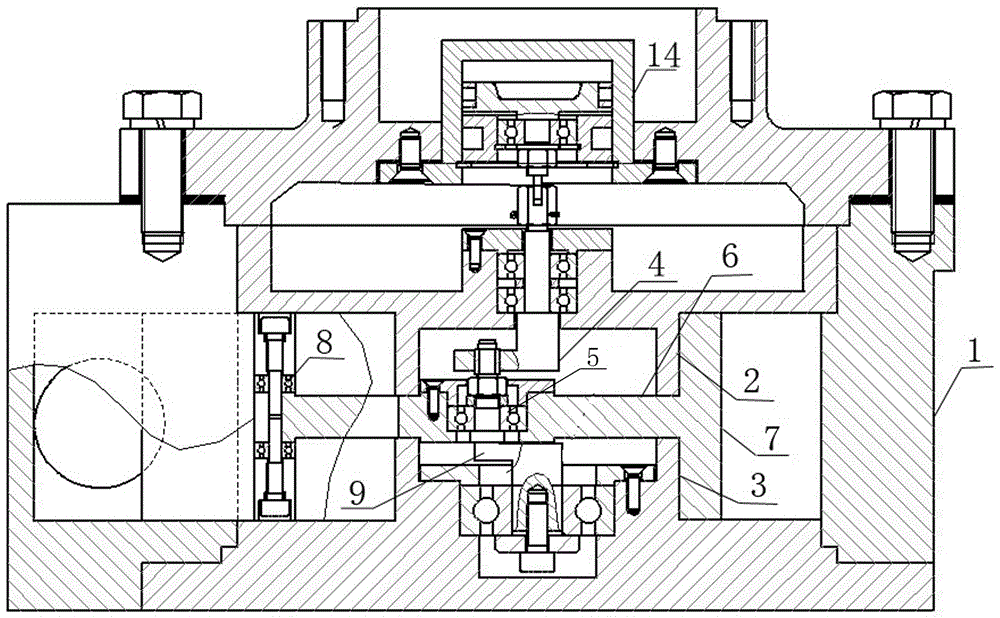

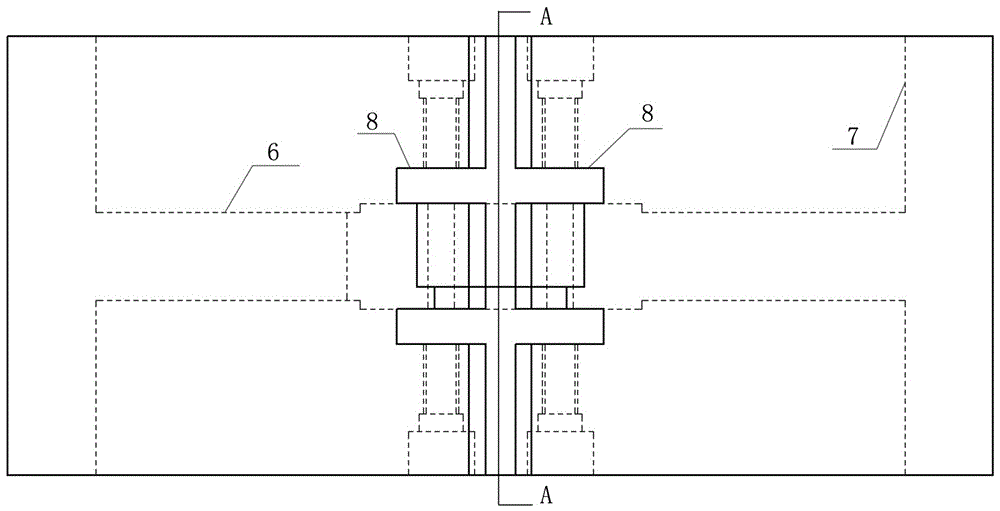

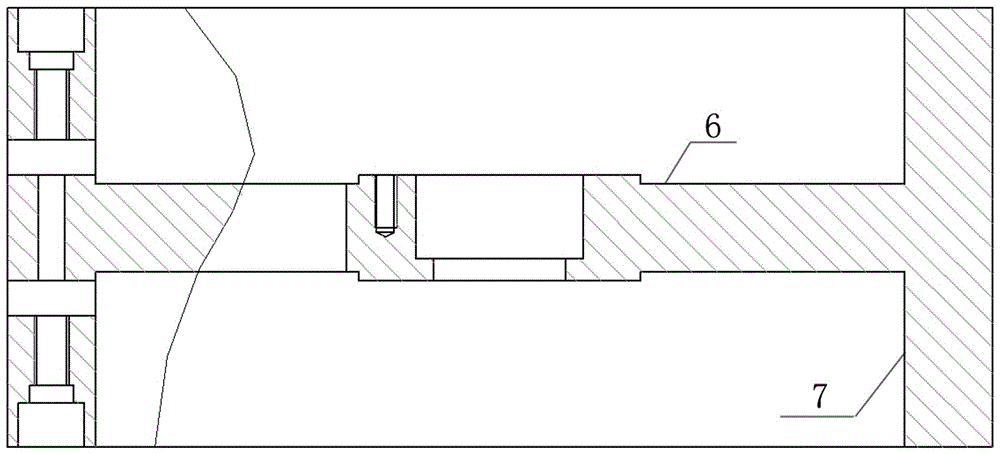

[0013] Suspended single-rotor gas flowmeter, including a hollow housing 1 and a rotor arranged in the hollow housing, the upper and lower positioning cylinders 2 and 3 with corresponding positions and the same outer diameter are fixed on the top and bottom of the hollow housing, and the upper positioning Inside the cylinder 2 and the lower positioning cylinder 3 are respectively provided with an upper crankshaft 4 formed by connecting a horizontal axis and a vertical axis, and a lower crankshaft 9 formed by connecting a first vertical axis, a second vertical axis, and a horizontal axis. The vertical axis of the crankshaft is arranged in the upper positioning cylinder 2, the second vertical axis of the lower crankshaft 9 is arranged in the lower positioning cylinder 3, the vertical axis of the upper crankshaft and the second vertical axis of the lower crankshaft 9 are coaxial, and the rotor Comprising a horizontal circular plate 6 and a circular ring 7 fixed around the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com