Kitchen and bathroom water stop platform aluminum formwork construction structure

A technology for water-stop table and kitchen and toilet, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, etc. Template sinking and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

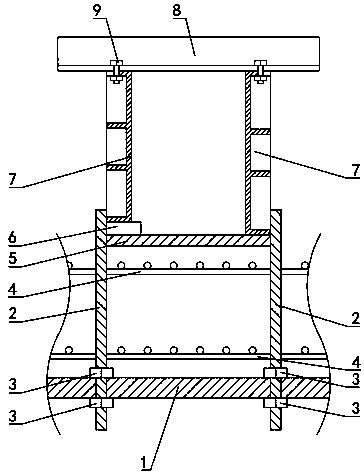

[0027] Such as figure 1 As shown: there are several horse stools arranged at intervals along the reverse sill formwork 7 , the lower end of the horse stool is fixedly connected with the top plate 1 , and both sides of the top of the horse stool are provided with positioning parts for positioning the reverse sill formwork 7 . The lower part of the reverse sill formwork 7 is arranged between the two positioning parts of the horse stool, thereby ensuring reliable positioning of the reverse sill formwork 7 and avoiding displacement of the reverse sill formwork 7 during pouring of concrete. The upper side of the top plate 1 is provided with a reinforced grid frame 4 .

[0028] The horse stool comprises cross bar 5 and upright bar, and in the present embodiment, upright bar is screw rod 2, and cross bar 5 is threaded steel, and cross bar 5 is horizontally arranged between two screw rods 2, and screw rod 2 is vertically arranged, and cross bar 5 The two ends of each are welded with ...

Embodiment 2

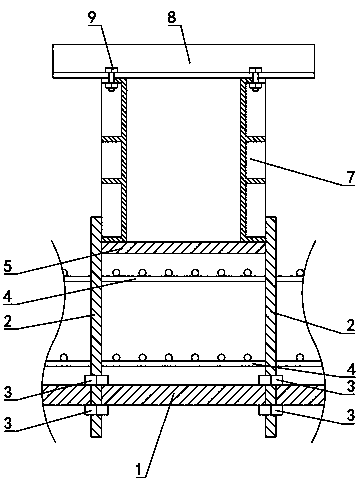

[0036] Such as figure 2 Shown: the difference between embodiment 2 and embodiment 1 is: the upper side of cross bar 5 is not provided with spacer 6, and the height of the floor slab poured on both sides of anti-sill formwork 7 is equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com