Green printing system and green printing method based on dual induction

A printing system and green technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of error prone, misoperation, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

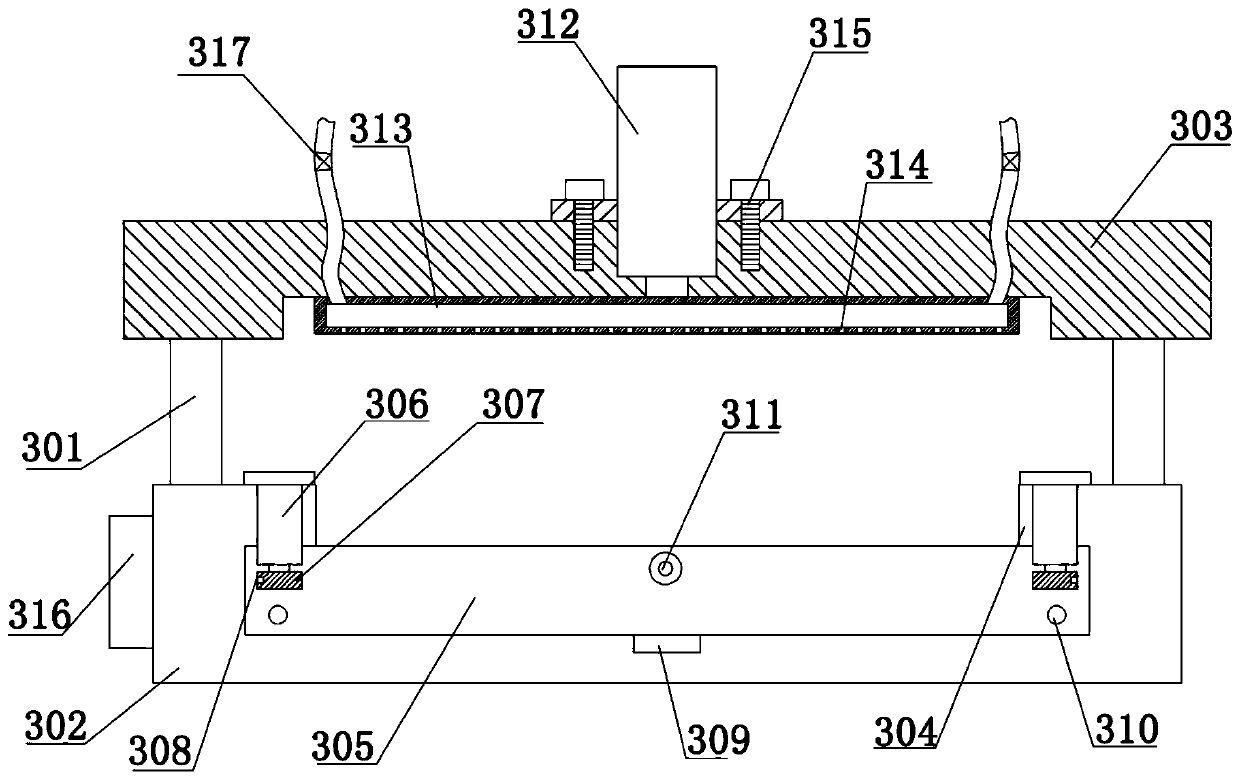

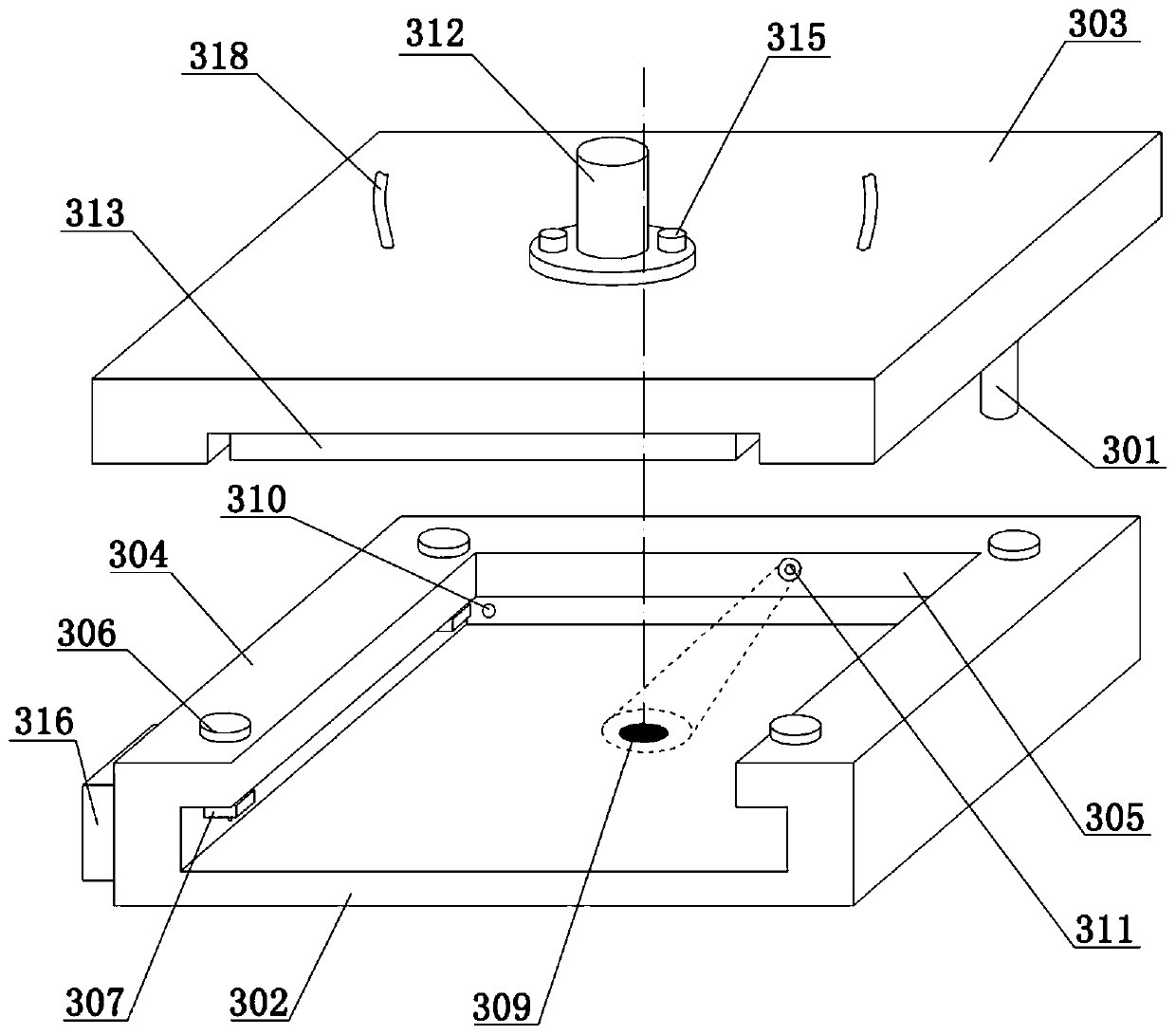

[0038] Example: such as Figure 1-3 As shown, a green printing system based on double induction includes a paper cutter 100, a printing machine 200 and a dryer 300. After the paper is cut by the paper cutter 100, the ink is printed by the printing machine 200, and then the operator The personnel are sent into the drying machine 300 for drying (the process from the paper cutter 100 to the printing machine 200, from the printing machine 200 to the drying machine 300 is manually transferred, and the printing machine 200 adopts an existing printing machine on the market), The dryer 300 includes a base 302 and a top cover 303 fixed by a plurality of pillars 301. The upper edge of the base 302 has a side convex edge 304 and a rear convex edge 305. The four corners of the side convex edge 304 are welded with a pneumatic cylinder 306. The pneumatic cylinder The output shaft of 306 is fixedly connected with the pressing plate 307, and the inner side of the pressing plate 307 is embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com