Au-Ag nanometer core-shell material taking carrageenan as reducing agent as well as preparation method and application thereof

A nano-core-shell, reducing agent technology, applied in the field of catalytic materials and bio-enzyme research, can solve problems such as the inability to meet the needs of multi-functional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

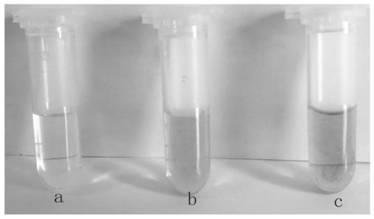

[0028] Dissolve 0.5g of carrageenan powder in 100mL of secondary water, heat and stir for 1h. Take 10 mL of the above solution and add 20 μL, 50 μL, and 100 μL of 0.02M chloroauric acid solution and 50 μL of 0.01M sodium hydroxide solution respectively, shake well, place in an electric blast drying oven, and react at 60°C for 12 hours. Cool to room temperature after reaction finishes, the result is as follows figure 1 shown.

[0029] figure 1 It was shown that the optimal addition amount of chloroauric acid was 50 μL, and the gold sol obtained was purple without precipitation, and the effect was the best. The gold sol prepared under this condition was labeled as AuNPs.

Embodiment 2

[0031] Dissolve 0.5g of carrageenan powder in 100mL of secondary water, heat and stir for 1h. Take 10 mL of the above solution and add 50 μL of 0.02M chloroauric acid solution and 50 μL of 0.01M sodium hydroxide solution into three parts, shake well, place in an electric blast drying oven, and react at 40°C, 60°C, and 80°C respectively 12h. Cool to room temperature after reaction finishes, the result is as follows figure 2 shown.

[0032] figure 2 It shows that the optimum reaction temperature is 60°C, and the obtained gold sol is purple without precipitation, and the effect is the best.

Embodiment 3

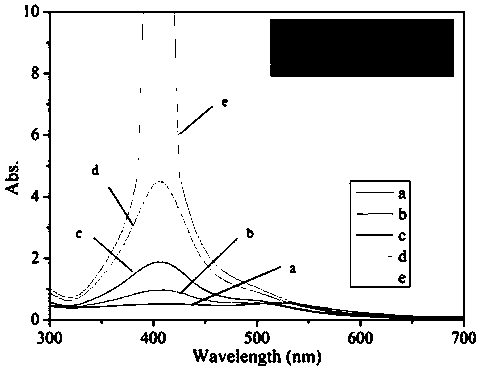

[0034] Dissolve 0.5g of carrageenan powder in 100mL of secondary water, heat and stir for 1h. Take 10 mL of the above solution, add 50 μL of 0.02M chloroauric acid solution and 50 μL of 0.01M sodium hydroxide solution, shake well, place in an electric blast drying oven, and react at 60°C for 12 hours. After the reaction, cool to room temperature, then prepare 1ml of gold sol prepared above, different volumes of 0.02M silver nitrate solution, 200μL of 0.01M sodium hydroxide solution, and secondary water to make a solution with a volume of 2ml, shake well, and place in In an electric blast drying oven, react at 80° C. for 2 h to obtain an orange Au-Ag nano core-shell material.

[0035] Regulating raw materials during the synthesis of Au-Ag (HAuCl 4 :AgNO 3 ) with a volume ratio of (a) 1:1 (b) 1:2 (c) 1:4 (d) 1:8 (e) 1:10 to obtain different Au-Ag nano core-shell materials. Add 1mL of the above-mentioned Au-Ag nano-core-shell materials with different raw material volume ratios...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com