A pulsed gas jet generator with adjustable excitation frequency and duty cycle

A technology of pulsed gas and excitation frequency, applied in the direction of injection device, injection device, etc., can solve the problems of small flow rate, high cost and risk, unable to meet research or application needs, etc., and achieve the effect of precise adjustment of rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

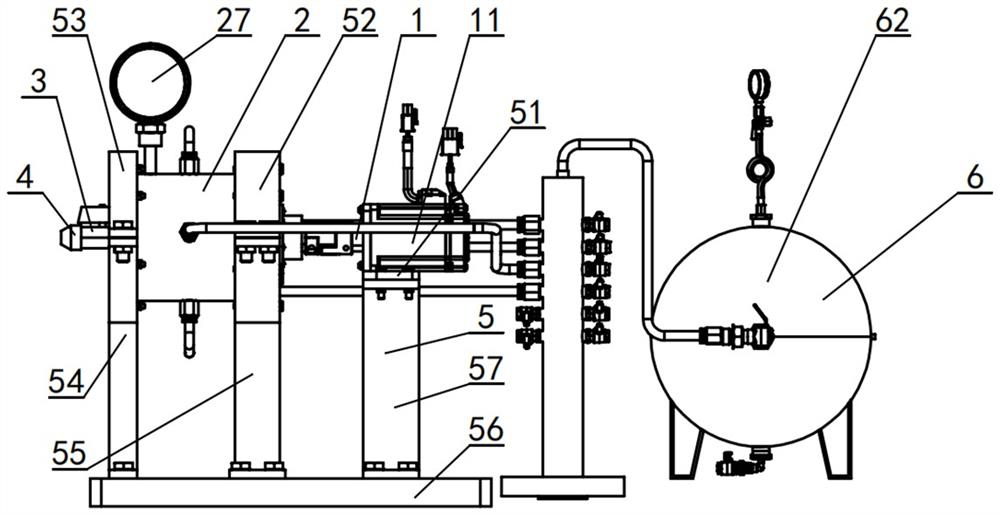

[0041]Seefigure 1 A pulse gas jet generator with adjustable excitation frequency and duty ratio mainly includes a rotating mechanism 1, a generating cavity mechanism 2 and an air supply mechanism 6.

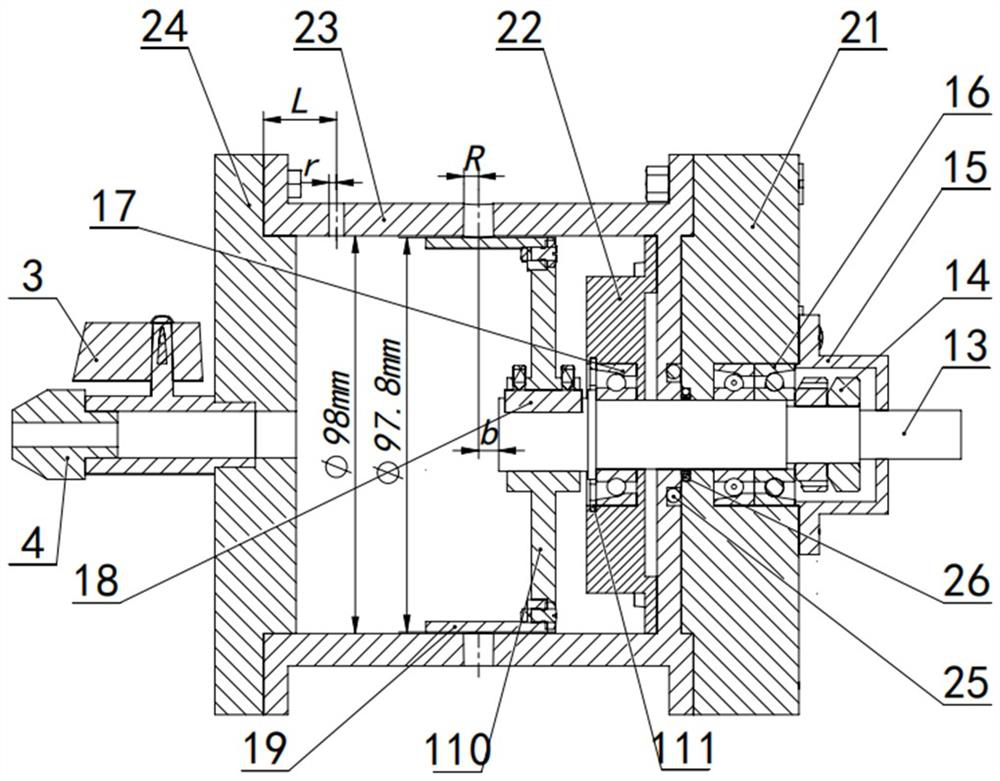

[0042]Seefigure 1 withfigure 2 , The rotating mechanism 1 includes a motor 11, a rotating shaft 13, and a rotating disk 110. Motor 11 is a Panasonic MHMF042L1U2M servo motor with a rated power of 400W, a rated speed of 3000r / min, and a rated torque of 1.27N·m. The rotating disk 110 is fixedly installed on one end of the rotating shaft 13 through a flat key 18 and a set screw, and the other end of the rotating shaft 13 is fixedly connected to the output shaft of the motor 11 through a coupling 12. The middle part of the rotating shaft 13 is fixed on the first flange 21 by a pair of first bearings 16 which are angular contact ball bearings. Four blades 19 are uniformly installed on the circumference of the rotating disk 110. The four blades 19 are parallel to the rotating shaft 13 and the a...

Embodiment 2

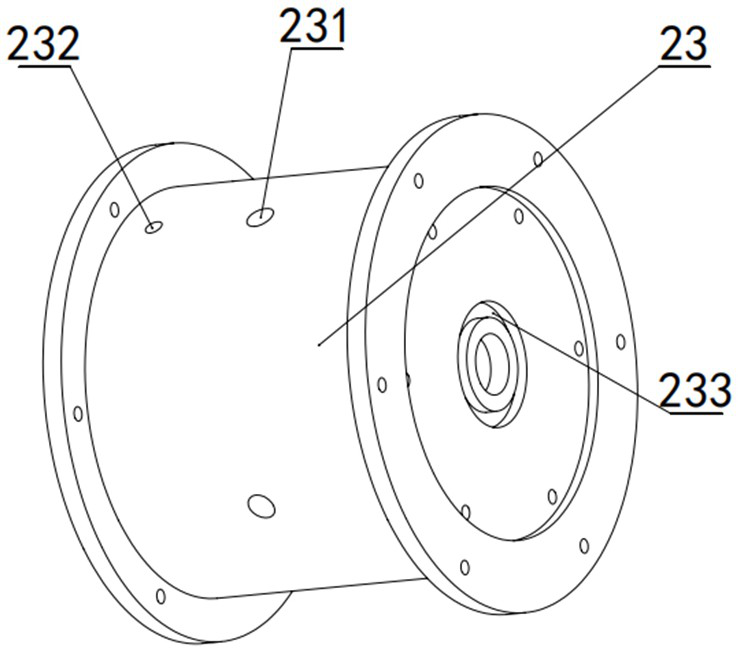

[0051]Example 2 The pulse jet has a duty ratio of 0.5, a frequency of 40 Hz, and a working pressure of 0.2 MPa. SeePicture 9 Under this working condition, a blade 19 with a central angle θ of 45°, a width c of 37.43mm, and a pulse jet duty ratio D=θ / 90°=0.5 are used. Under this working condition, the motor speed n is 600r / min, corresponding to the frequency f=4n / 60=40Hz. Before the device works, close the first ball valve 3 and the second ball valve 61; when it starts to work, adjust the working pressure of the pressure reducing valve 63 to 0.2MPa, set the motor speed to 600r / min, open the second ball valve 61, and pressure the gas tank 62. Continuously fill the cylinder body 23 with high-pressure gas through the four air inlets 231. When the value of the first pressure gauge 27 shows 0.2MPa, open the first ball valve 3, and after the air flow is stable, start the motor 11, repeat Example 1 Operation.

Embodiment 3

[0053]Example 3 The pulse jet has a duty ratio of 2 / 3, a frequency of 20 Hz, and a working pressure of 0.5 MPa. Before the device works, replace the blade 19, seePicture 10, The central angle θ of each blade 19 is 60°, and the width c is 48.9 mm. According to the calculation formula of the duty cycle D=θ / 90°=2 / 3. Under this working condition, the motor 11 rotates speed n to 300r / min, corresponding to the pulse frequency f=4n / 60=20Hz. After installation, close the first ball valve 3 and the second ball valve 61; when starting to work, adjust the pressure reducing valve 63 to a working pressure of 0.5MPa, set the motor speed to 600r / min, open the second ball valve 61, and the pressure tank 62 passes The four air inlets 231 are continuously filled with high-pressure gas into the cylinder body 23. When the value of the first pressure gauge 27 shows 0.5 MPa, the first ball valve 3 is opened. After the air flow is stable, the motor 11 is started, and the example 1 is repeated. operating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com