Vegetable seedling-cultivating and transplanting machine

A technology for raising seedlings and transplanting vegetables, applied in the field of agricultural machinery, can solve the problems affecting the growth of seedlings, large soil layer at the bottom, and single plant feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

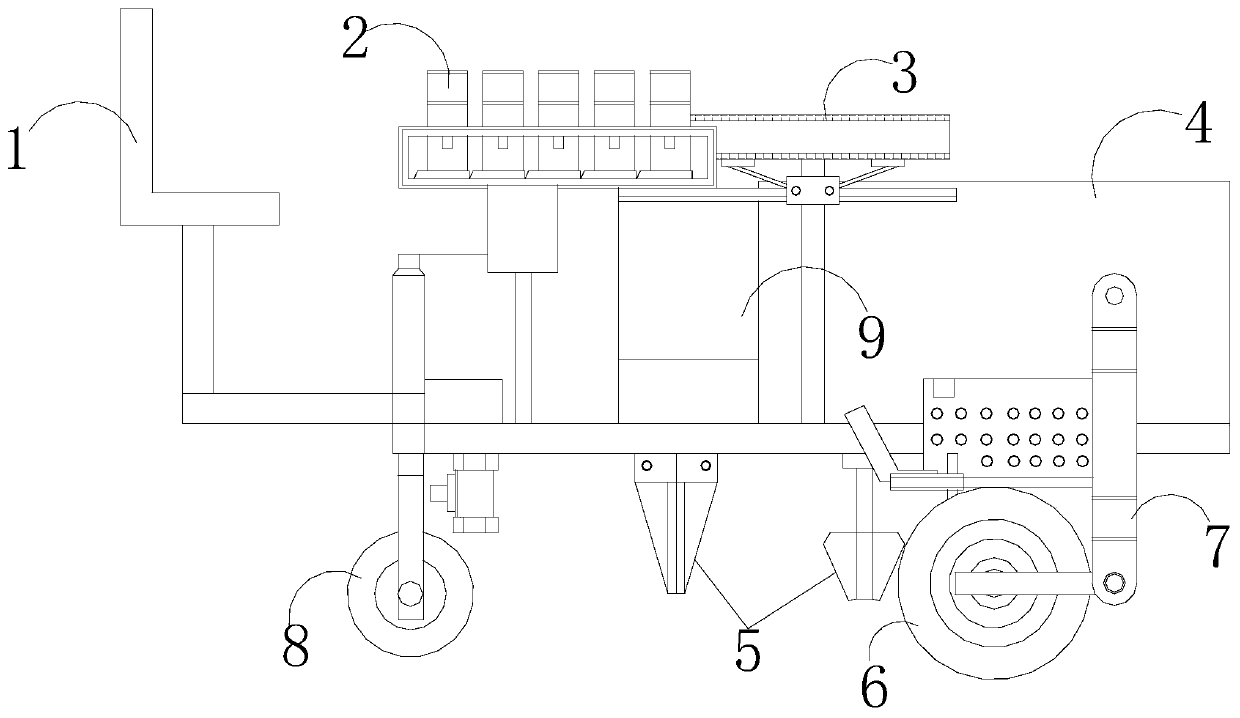

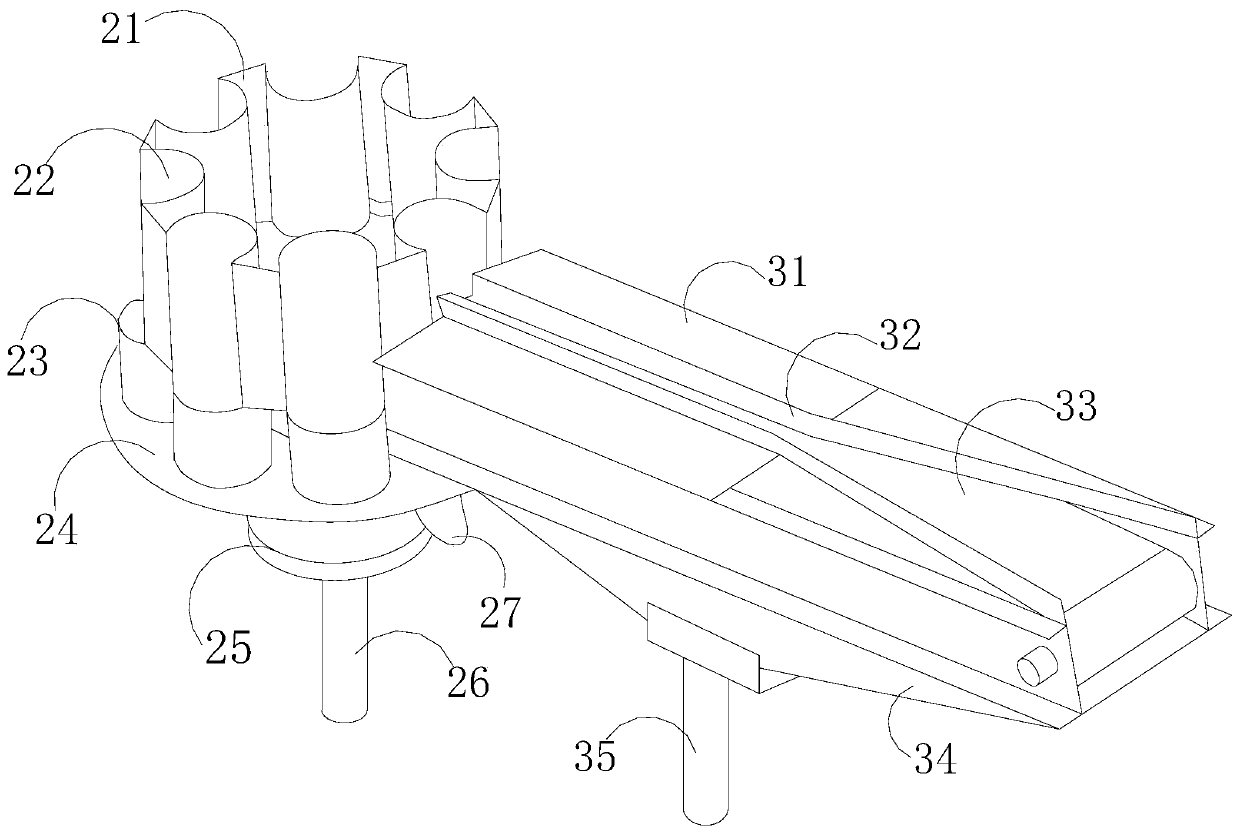

[0035] Such as figure 1 , figure 2 , Figure 8 , Figure 9As shown, the present invention provides a kind of vegetable seedling transplanting machine, its structure comprises seat 1, rotary cup seedling throwing mechanism 2, seedling delivery device 3, frame 4, hole opener 5, rear wheel 6, support 7, front Wheel 8, seedling guide tube 9, the seat 1 is installed on the left side of the frame 4, the frame 4 is mechanically connected with a rotary cup seedling throwing mechanism 2 and a seedling delivery device 3, and the rotary cup seedling throwing mechanism 2 is connected with the seedling guide tube 9, and the bottom of the frame 4 is mechanically connected with the front wheel 8 and the rear wheel 6, and the hole opener 5 is arranged between the front wheel 8 and the rear wheel 6 at the bottom of the frame 4. The support 7 is connected to the rear wheel 6 and the frame 4, and the rotor cup seedling throwing mechanism 2 is provided with a rotor connecting plate 21, a roto...

Embodiment 2

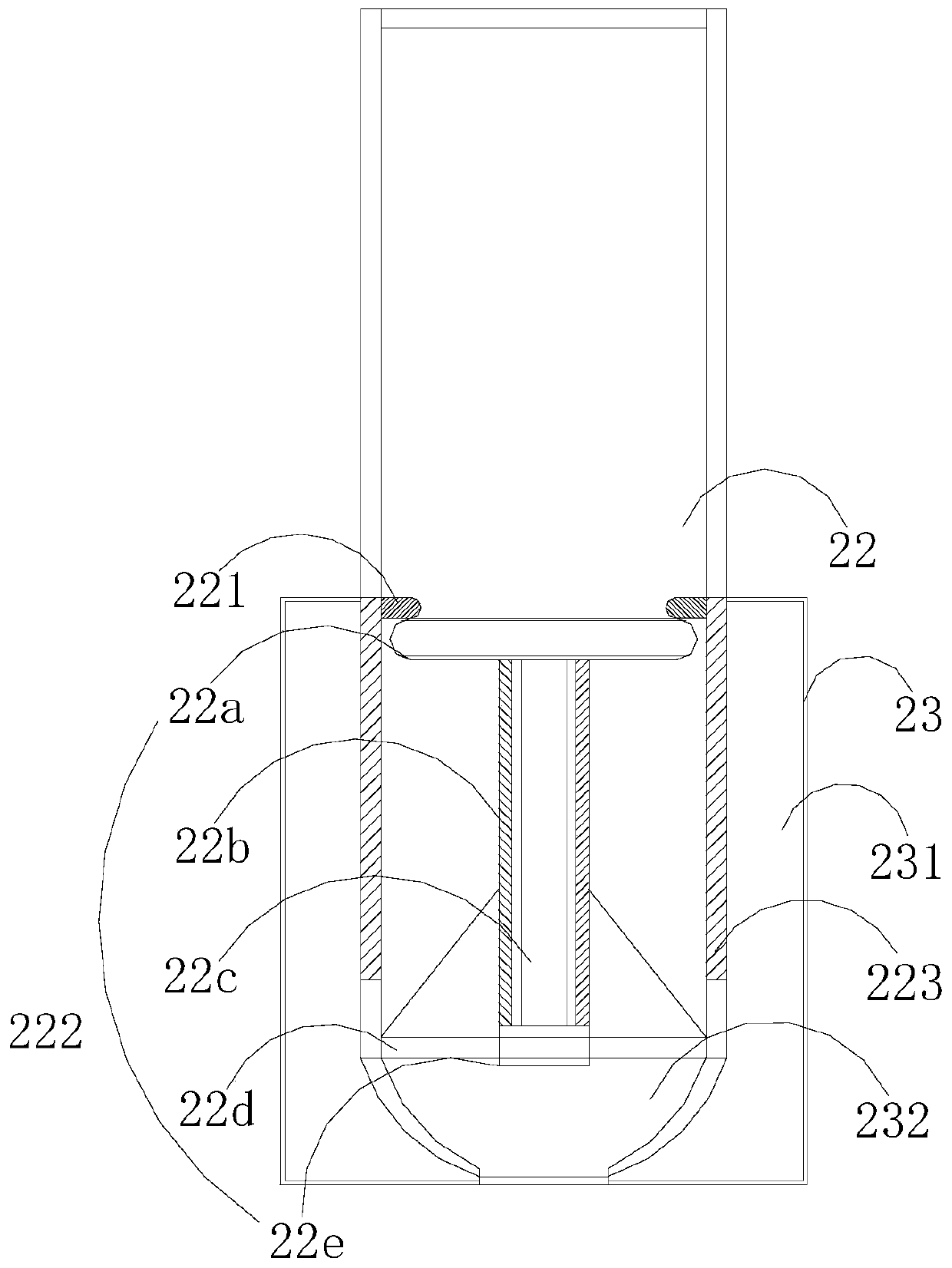

[0038] Such as Figure 1-Figure 5 As shown, based on the fact that embodiment 1 can effectively improve the feeding efficiency of seedlings without harming the seedlings, through the mutual cooperation of the following structures, the rotor 22 is provided with a cup body chuck 221 and a turntable in the pot. 222. Isolation edge 223, the cup body chuck 221 is fixed on the inner surface wall of the rotor cup 22 and is in contact with the bowl inner turntable 222, and the bowl inner turntable 222 is set in the cavity surrounded by the isolation edge 223 Inside, the cup base 23 is composed of a hollow cavity 231 and a bowl trough 232, the bowl trough 232 is located at the bottom of the bowl inner turntable 222, and the bowl inner turntable 222 and the cavity are both arranged at the bottom of the hollow cavity 231 Inside, the turntable 222 in the pot includes a seedling seat 22a, a guide body 22b, a screw 22c, a support plate 22d, and an engagement port 22e. The bottom of the seed...

Embodiment 3

[0041] Such as Figure 1-Figure 9 As shown, based on Example 1 and Example 2, the feeding efficiency of seedlings can be effectively improved without harming the seedlings, and feeding from the side of the rotor cup is also accompanied by the lifting of the seedling holder to increase the internal load of the rotor cup. The accuracy of the seedlings, the protection screw rod is not damaged by soil pollution, and reminds people to carry out soil dumping in time, and through the mutual cooperation of the following structures, the sorting baffle plate 31 includes a traction angle 311, a driver 312, a first pressing body 313, The second pressing body 314, the traction angle 311 is arranged between the channel baffle plate 32 and the first pressing body 313, the traction angle 311 is a telescopic semicircular structure, the first pressing body 313 and the second pressing body 314 is controlled by the driver 312, and the cooperation of the first press-fit body 313 and the second pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com