Connector

A connector and body technology, which is applied in the field of connectors with redundant object control function, can solve the problems of short service life of connectors, increased plug-in force of connectors, unbalanced force on products, etc. The effect of reducing and reducing the interference distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

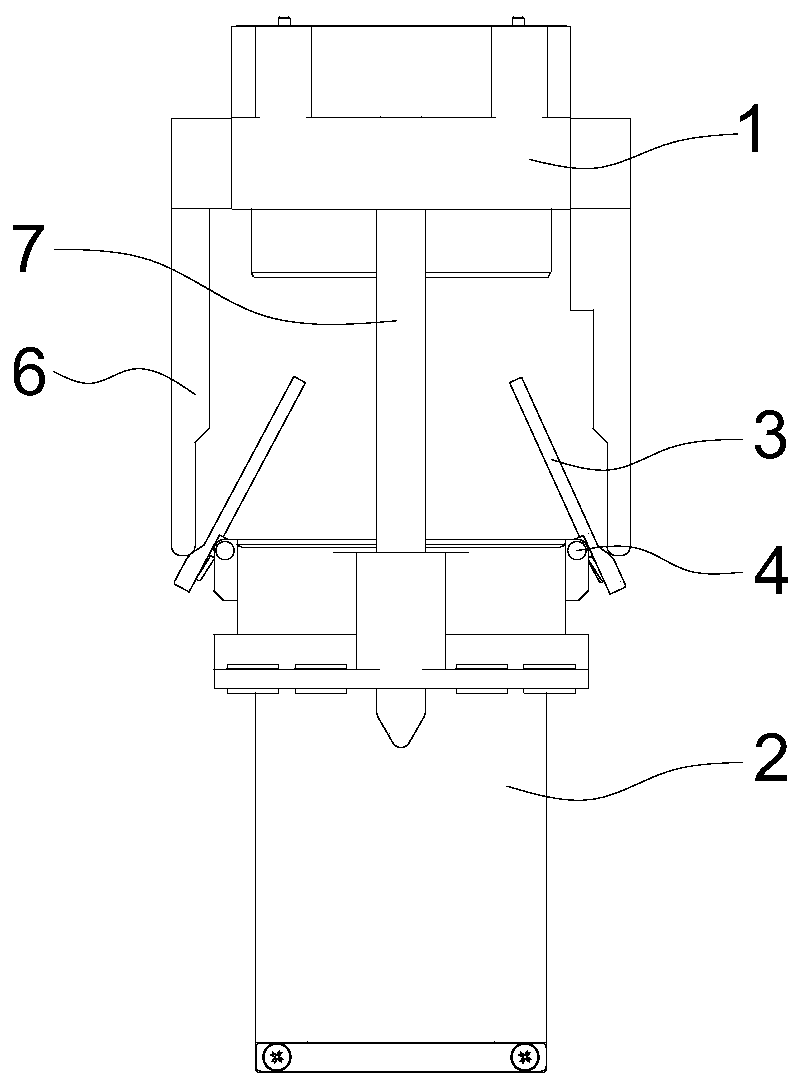

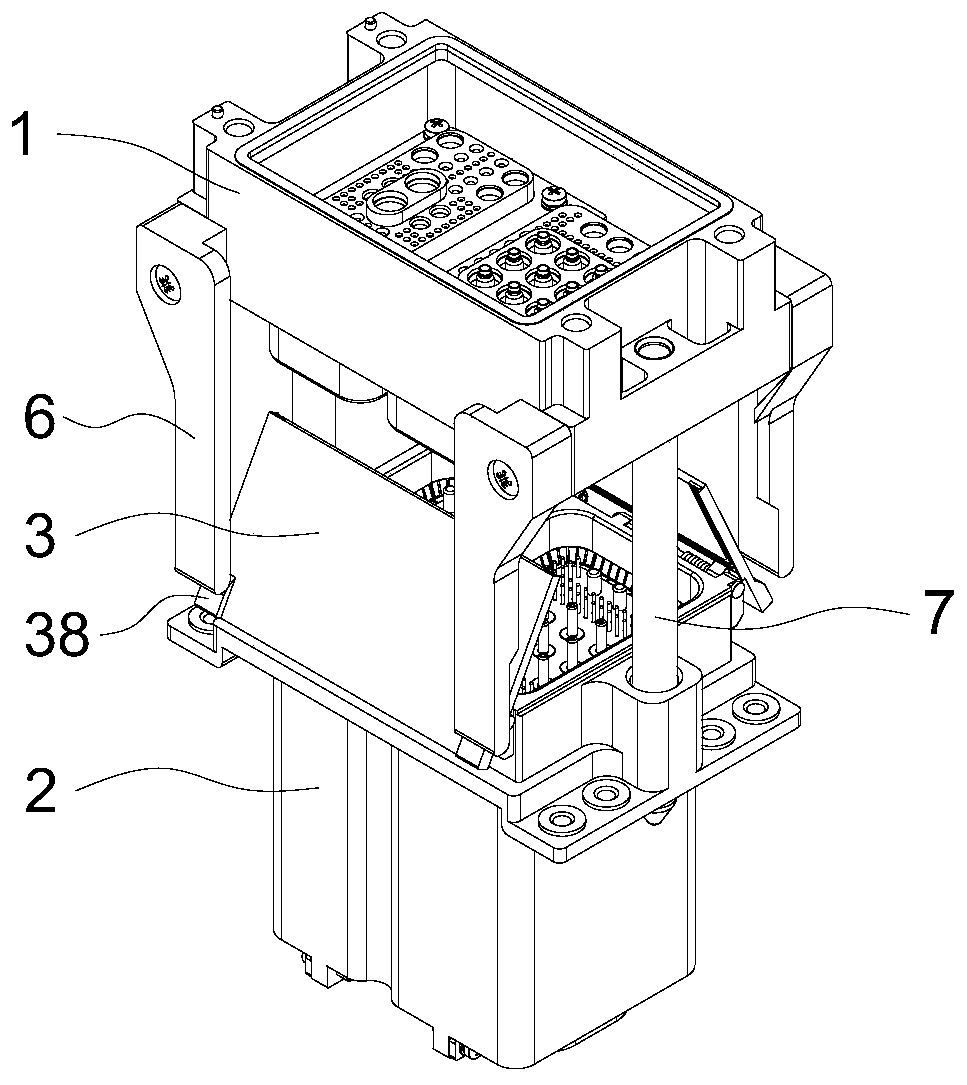

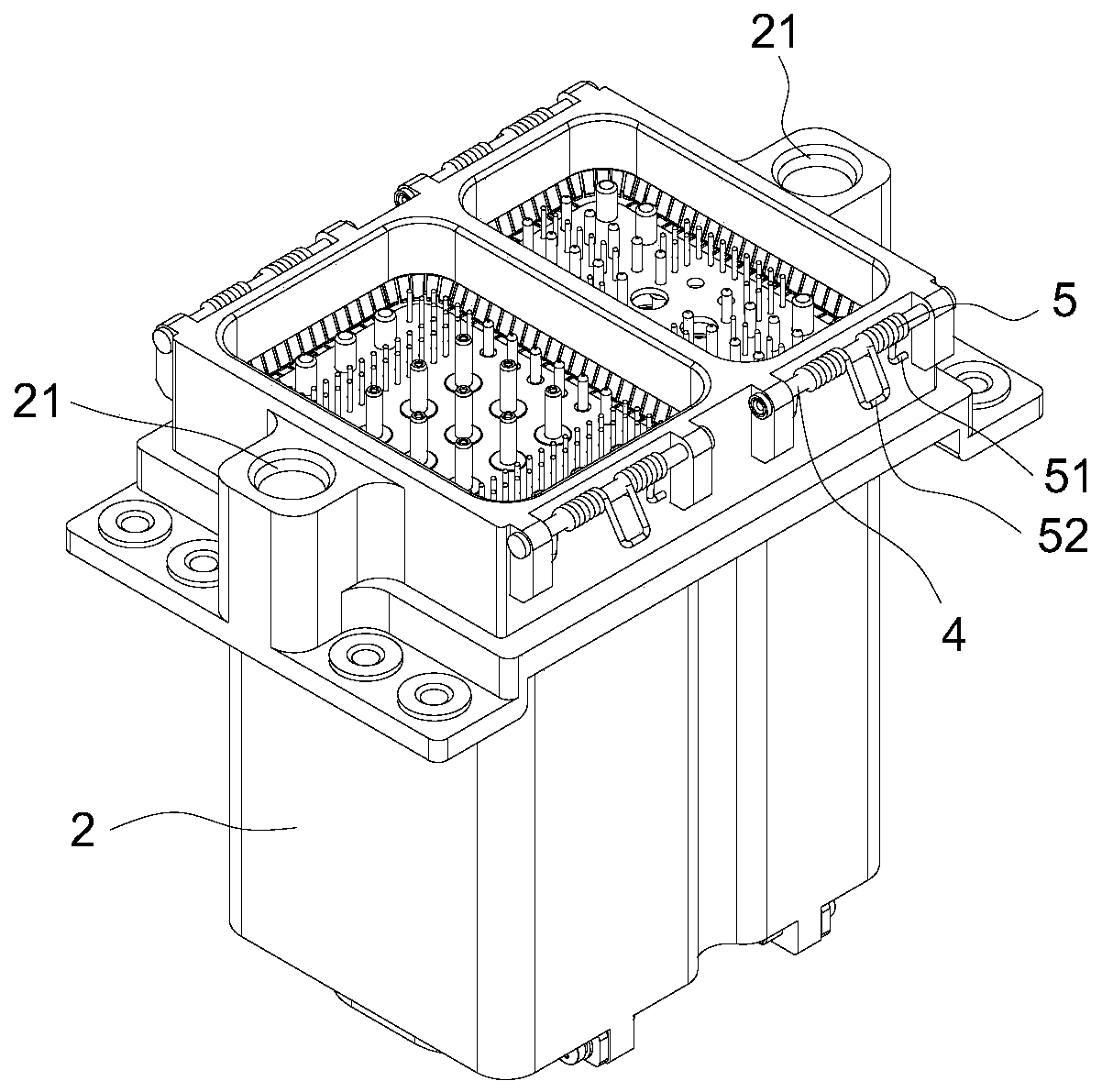

[0031] Such as Figure 1 to Figure 6As shown, a connector includes a first body 1, a second body 2 and a dustproof cover 3, the first body 1 and the second body 2 can be movably inserted into one body, and the dustproof cover 3 is a split structure , so that when the connectors are docked, the force on both sides is equal, avoiding the increase of the insertion force caused by eccentricity on one side, thereby avoiding the serious wear on one side, prolonging the life of the connector, and making the dust cover 3 open and close at the same time The required height is reduced by half, which effectively reduces the interference distance, shortens the mating stroke of the connector, and improves the space utilization rate. The dust cover 3 is provided with a turntable 31, and the turntable 31 separates the two sides of the dust cover 3 into The closed wing 32 and the empennage 33, the turntable 31 is rotationally connected with the second body 2 through the rotating shaft 4, the ...

Embodiment 2

[0038] like Figure 7 , Figure 8 As shown, on the basis of the structure of Embodiment 1, the structure of the dust cover 3 is improved as follows:

[0039] The dust cover 3 includes a first cover plate 34 and a second cover plate 35 that are split in two, the end of the closing wing 32 of the first cover plate 34 is provided with a first convex wing 36, and the closing wing 32 of the second cover plate 35 The end is provided with a second convex wing 37. When the dust cover 3 and the end surface of the second body 2 are closed, the lower end surface of the second convex wing 37 is attached to the end surface of the second body 2, and the upper end surface of the second convex wing 37 It fits with the lower end surface of the first convex wing 36 to form a "Z"-shaped staggered overlapping structure, which solves the problem of gaps when the first cover plate 34 and the second cover plate 35 are closed, and avoids the excess from the first cover. The gap between the plate 34...

Embodiment 3

[0043] like Figure 9 , Figure 10 As shown, on the basis of the structure of the second embodiment, the connector further includes a gasket 8, the gasket 8 is arranged between the dust cover 3 and the end surface of the second body 1, and the gasket 8 is on the dustproof surface. When the cover 3 is closed, one side of the gasket 8 is attached to the dustproof cover 3, and the other side of the gasket 8 is attached to the end face of the second body 2, so as to isolate the inner cavity of the second body 2 from the external environment and prevent dust and foreign matter Enter, and further improve the excess control effect.

[0044] The connector provided by the present invention avoids severe wear on one side by providing a split dust cover, prolongs the service life of the connector, shortens the mating stroke of the connector, and improves the space utilization rate. By setting the trigger device, when the connectors are mated or separated, the dust cover can be automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com