Unit cell structure made of three-dimensional periodic composite material

A composite material and three-dimensional cycle technology, applied in the field of vibration reduction, can solve problems such as bearing micro-vibration, restricting the improvement of machining accuracy, and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

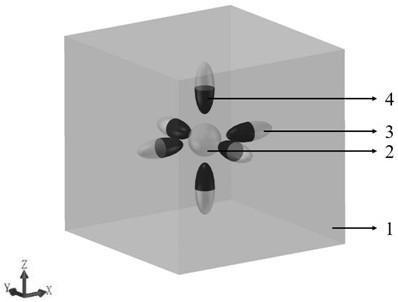

[0024] Such as figure 1 As shown, this embodiment is a unit cell structure of a three-dimensional periodic composite material, which includes a unit cell matrix 1 and a three-dimensional entity 3.

[0025] The unit cell matrix 1 is in the shape of a cube, and the body center is provided with a body center cavity 2; the body center cavity 2 is a spherical cavity.

[0026] The number of three-dimensional entities is 6, which are evenly distributed on the three lines of opposite face centers of the cube-shaped unit cell matrix 1, and are ellipsoid-shaped cavities. The distances between the six three-dimensional entities 3 and the body-centered cavity 2 are the same. , And the three-dimensional entity 3 is filled with a scatterer 4; the scatterer 4 is not filled or completely filled with the three-dimensional entity, and the scatterer 4 is filled from the side close to the body core cavity 2.

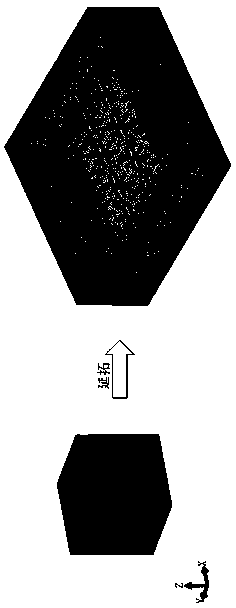

[0027] Such as image 3 As shown, the unit cell structure of the three-dimensional periodic co...

Embodiment 2

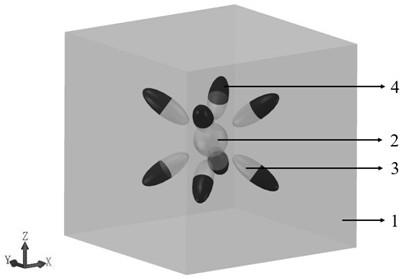

[0030] This embodiment 1 provides a unit cell structure of another three-dimensional periodic composite material, and its composition is similar to that in embodiment 1, except that: figure 2 As shown, the number of three-dimensional entities is 8, which are evenly distributed on the four diagonals of the cube-shaped unit cell matrix 1.

[0031] The scatterer 4 is also not filled with three-dimensional entities, but the scatterer 4 is filled from the side away from the body-centered cavity 2.

[0032] Such as Figure 5 As shown,

[0033] The scatterer 4 is a metal material scatterer; the unit cell matrix 1 is a foam, rubber, polyurethane or foamed aluminum matrix.

[0034] Example 2: Figure a =6mm, d =1mm, l 1 =1.6mm, l 2 =0.6mm, l 3 =0.8mm, l 4 =0.8mm, where l 1 Represents the major axis of the ellipsoid, l 2 Represents the minor axis of the ellipsoid, l 3 Indicates the distance from the vertex of the ellipsoid to the center of the cube, l 4 Represents the filling length of the scat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com