Method for judging resistance encountering of electric lifting table by utilizing wavelet modulus maximum

A judging method and modulus maximum technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve problems such as lack, difficulty in accurately identifying clamping conditions, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Electric lift table is the main form of electric lift table such as figure 1 Shown: as figure 1As shown, the mechanical structure of the automatic lifting table is divided into six parts: the desktop, the bracket, the connecting shaft, the motor controller, the column and the base. The desktop 1 is connected with the support 3 through the connecting shaft 2, and fixed by screws and bolts. The middle structure of the column 4 is nested by two connecting rods, the motor controller 5 controls the motor at the top of the column 4, and the synchronous control of multiple motors by the single-chip microcomputer as a whole realizes the highly precise lifting of the automatic lifting table. The column 4 is connected to the base 6 through a connecting shaft to provide stable support for the entire table.

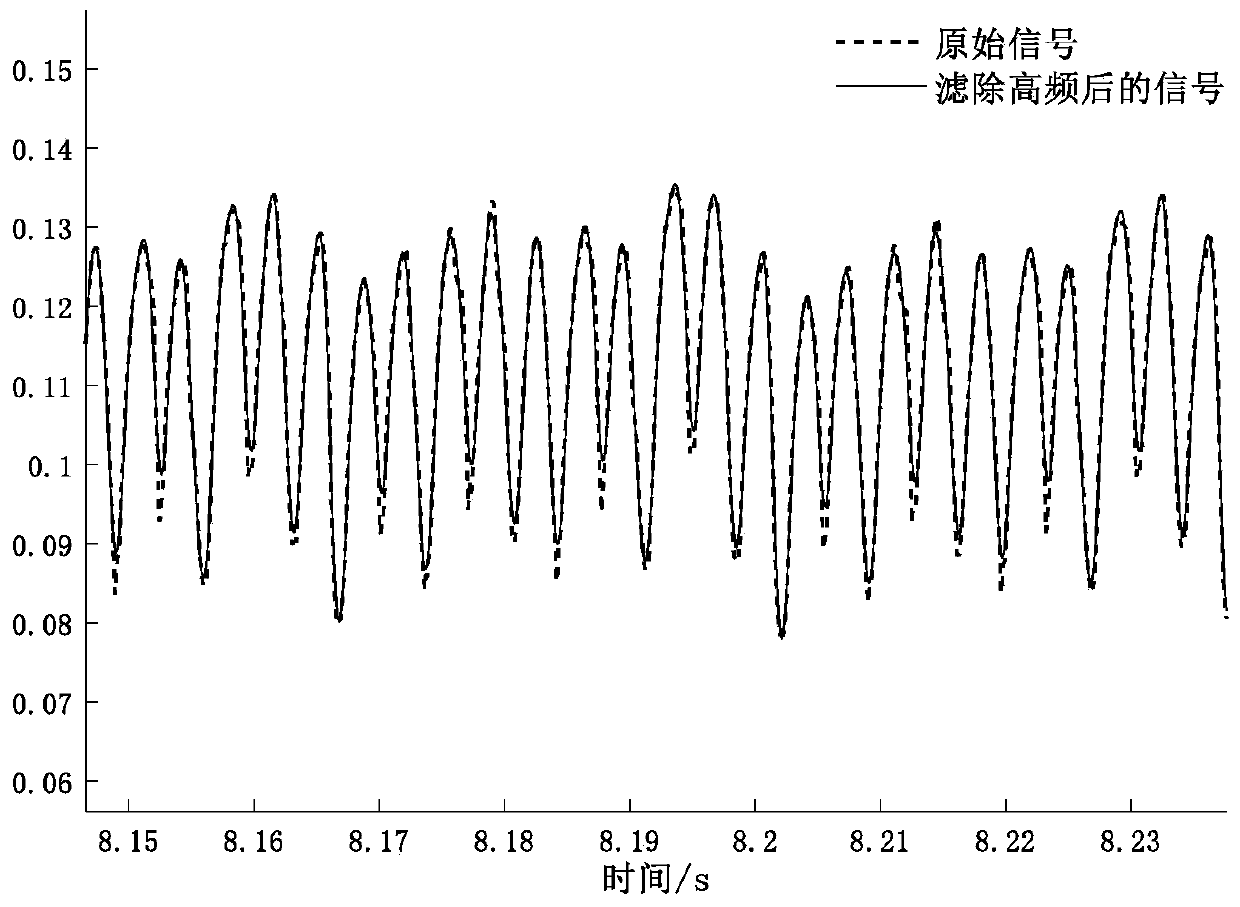

[0047] In order to enhance the market competitiveness of the product, the motor current acquisition adopts the bus resistance sampling method, and the speed signal adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com