Semiconductor laser low-temperature testing device

A technology for low-temperature testing and lasers, which is applied in semiconductor lasers, single semiconductor device testing, and optical instrument testing. It can solve problems such as unfavorable batch testing, long testing cycles, and cumbersome steps to replace devices, so as to avoid condensation and improve dehumidification. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

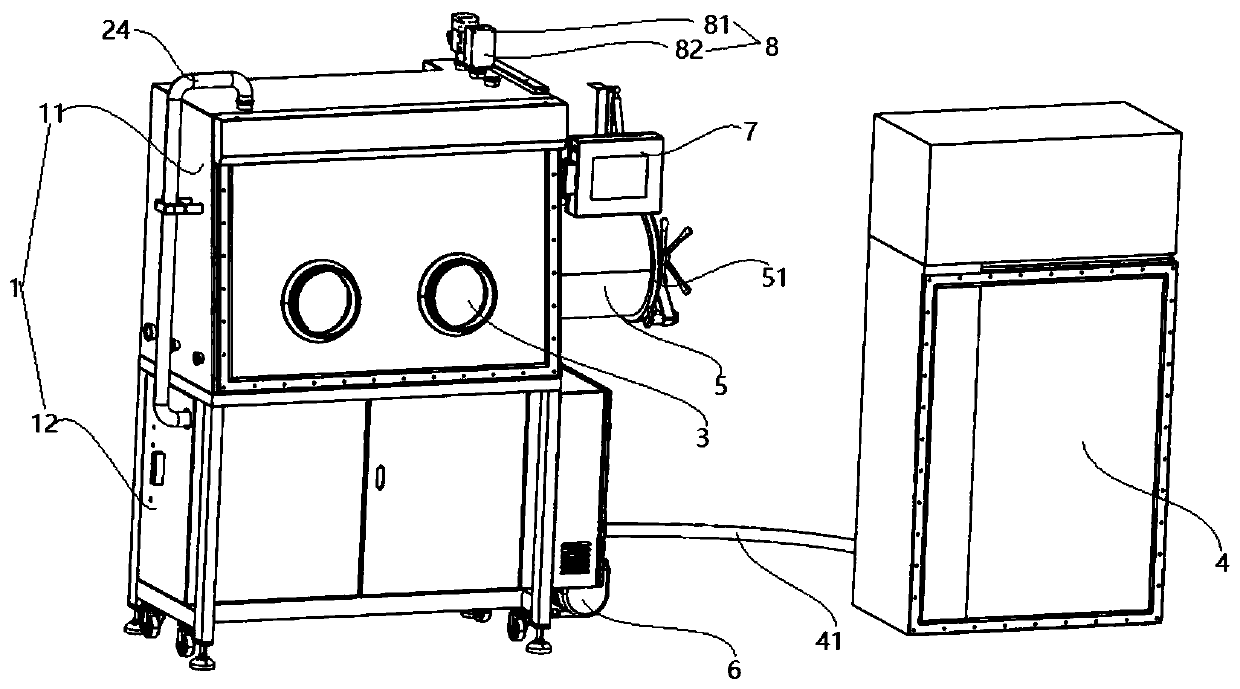

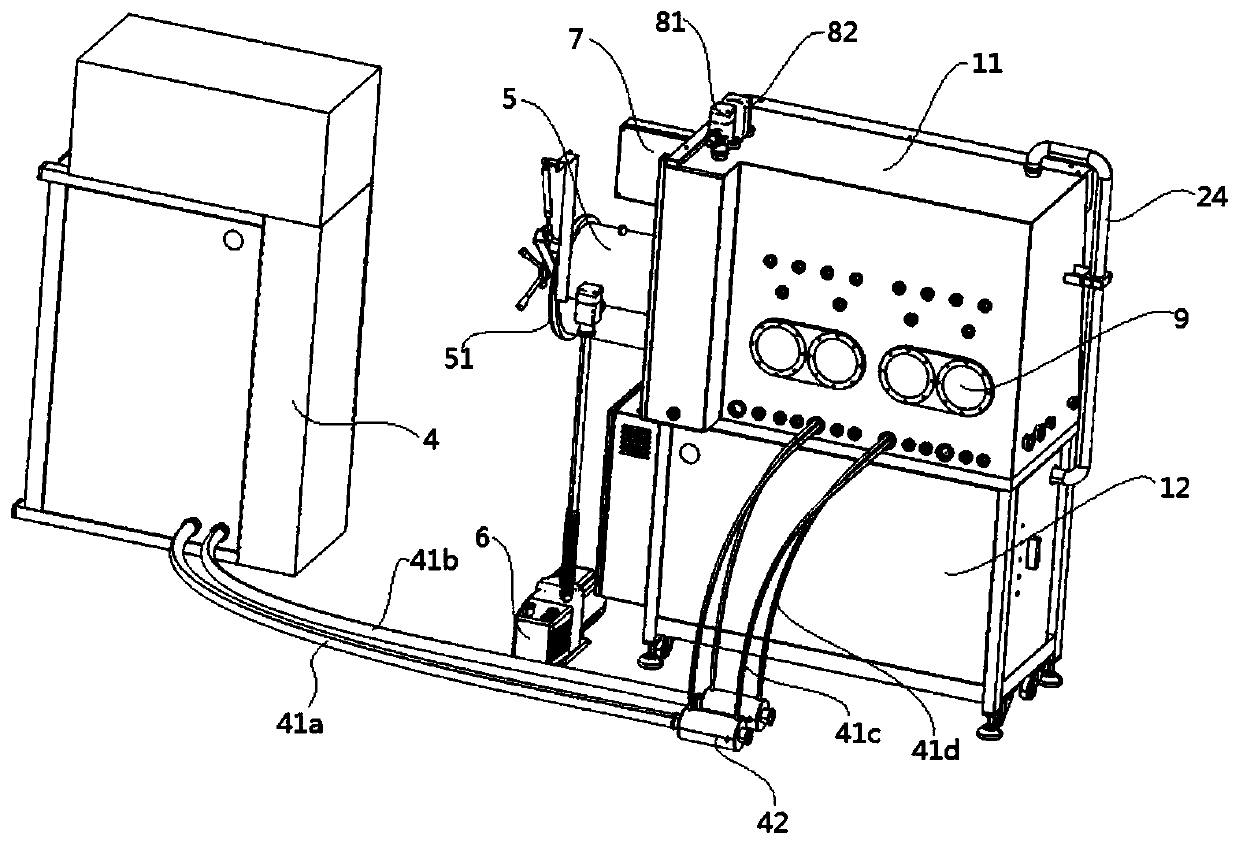

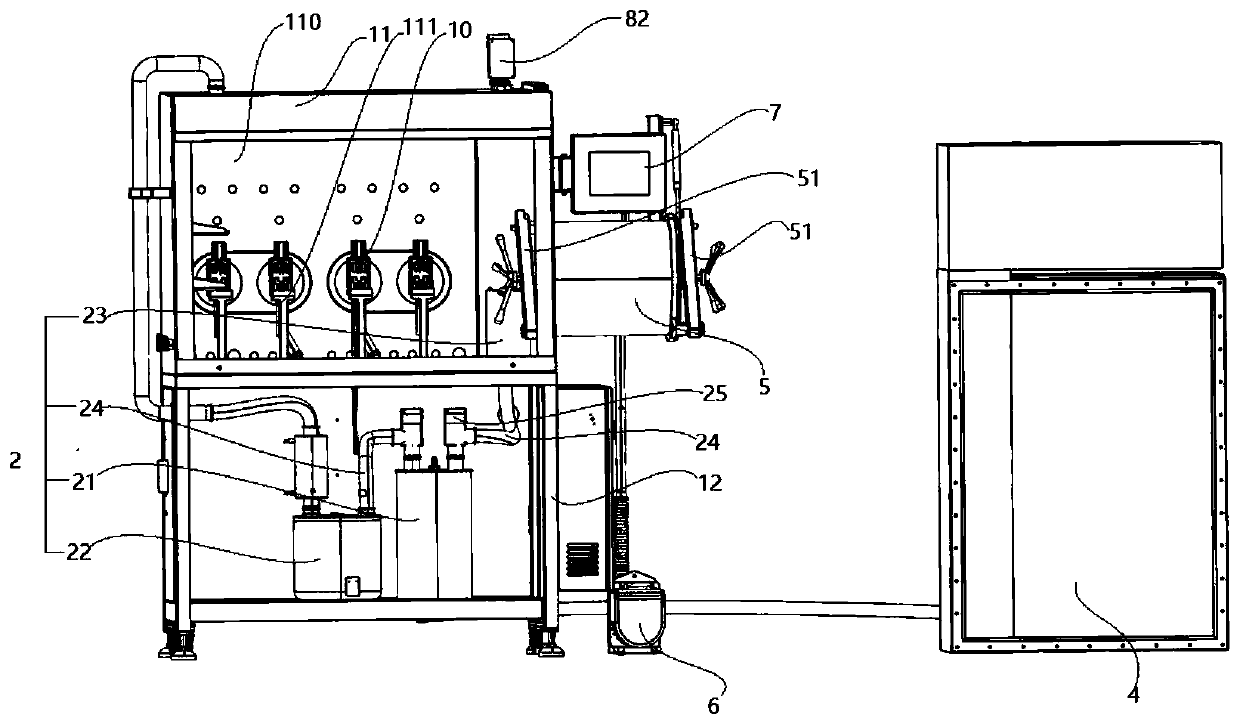

[0054] This embodiment provides a semiconductor laser low temperature testing device, such as Figure 1 to Figure 5 As shown, it includes a low-temperature box 1, an anti-condensation assembly 2, a refrigeration device 4 and an operating part 3, wherein the low-temperature box 1 has an airtight cavity 110 for placing a laser device to be tested (not shown), and the airtight The cavity 110 has at least one first air inlet (not shown) and a first air outlet (not shown); A closed loop is formed; the refrigeration device 4 is connected to the low-temperature box 1 for cooling the laser device to be tested to reach the low temperature condition required for the test; the operating part 3 is arranged on the low-temperature box 1 for replacing the laser device to be tested to The goal of replacing the laser device to be tested without opening the sealed cavity 110 is achieved, and the test can be performed continuously, which is beneficial to batch testing.

[0055] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com