Tunnel drainage pipe crystallization prevention and control system and method

A tunnel drainage and tunnel technology, applied in drainage, mine/tunnel ventilation, earthwork drilling and mining, etc., can solve the problems of slowing down of water flow and clogging of crystals, and achieve the effects of increasing drainage speed, delaying clogging and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

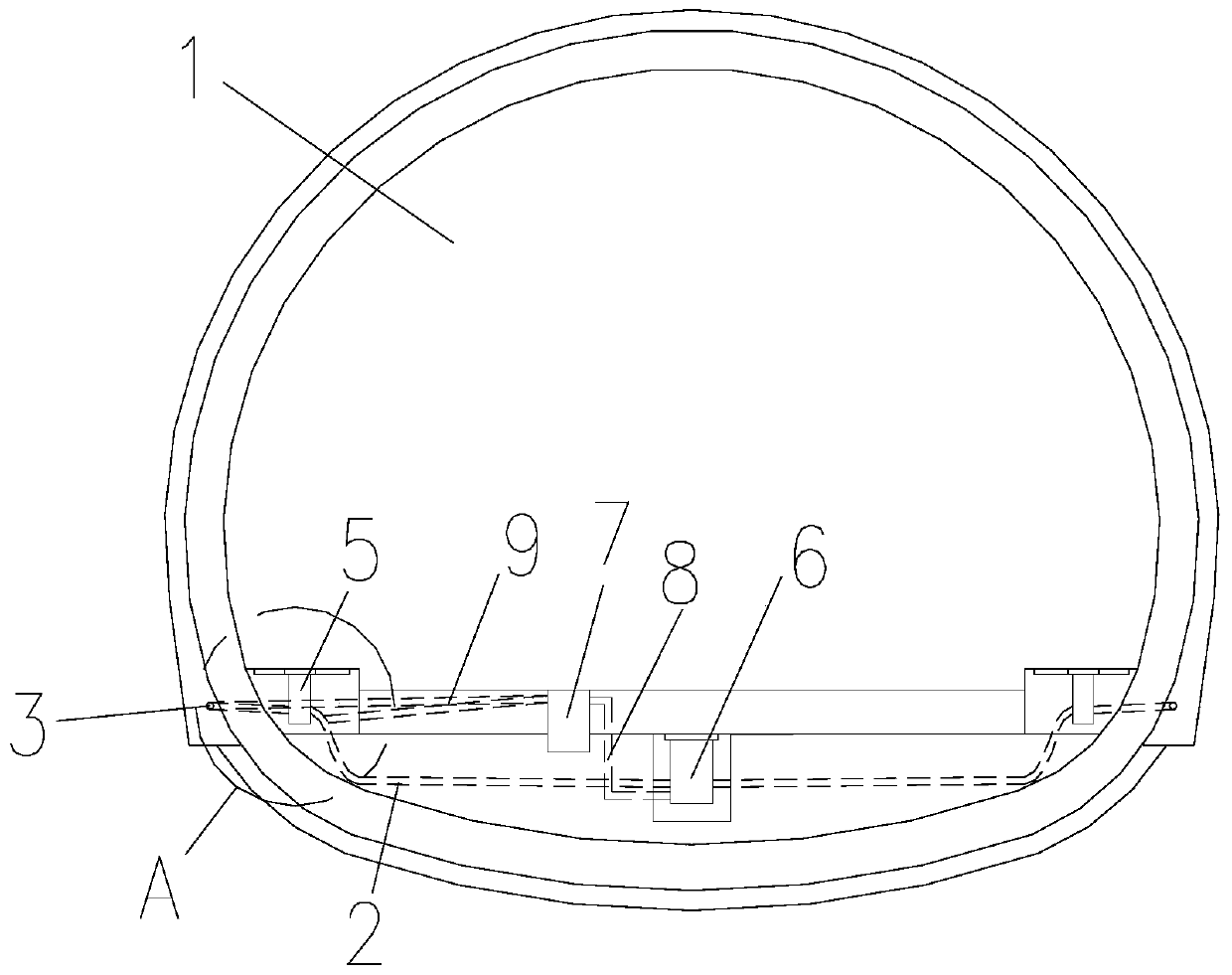

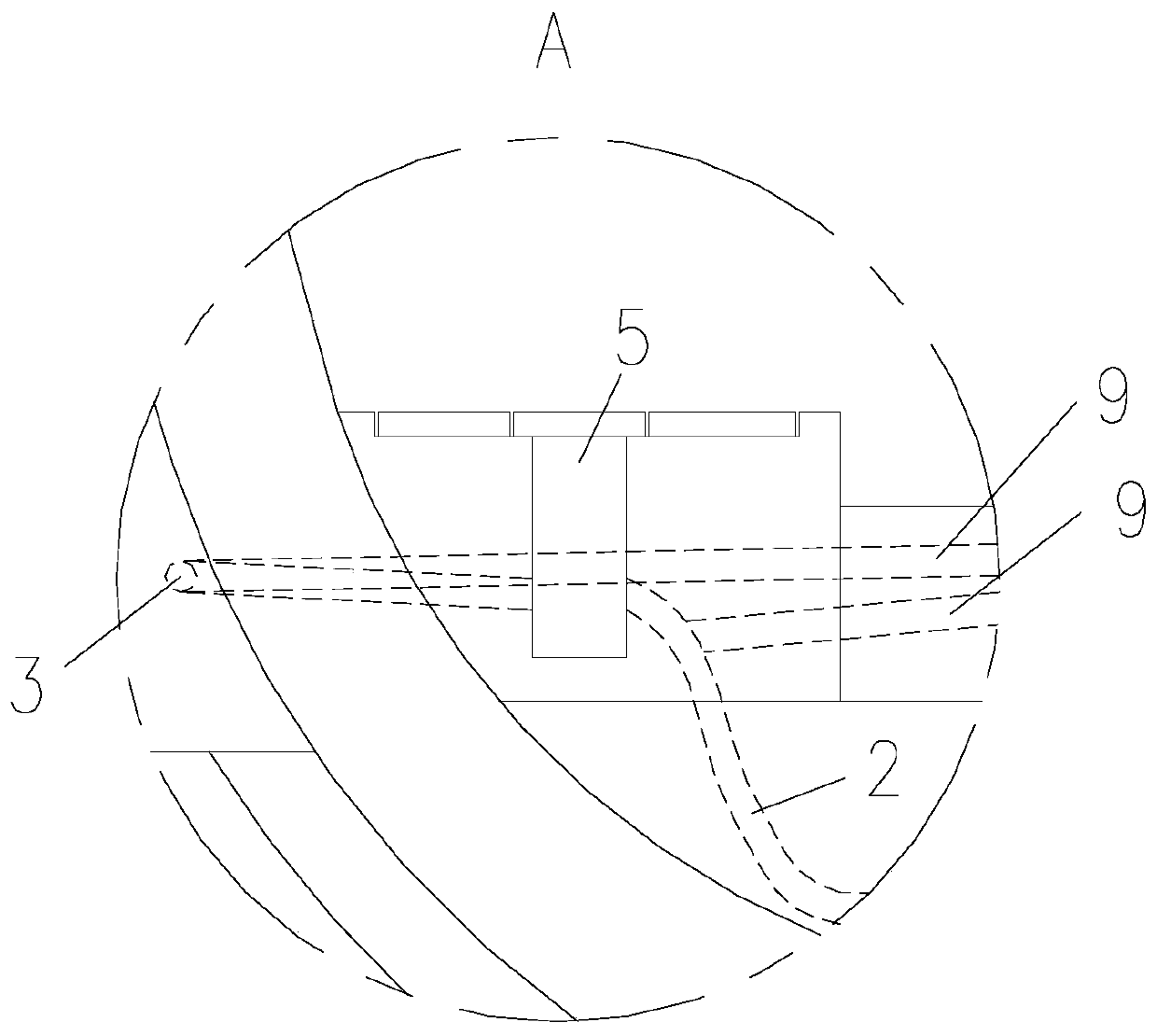

[0080] see Figure 1-Figure 3 , The embodiment of the present invention provides a tunnel 1 drainage pipe crystallization prevention system, which includes a water tank 7 , an outlet pipe 9 and a water suction pipe 8 . .

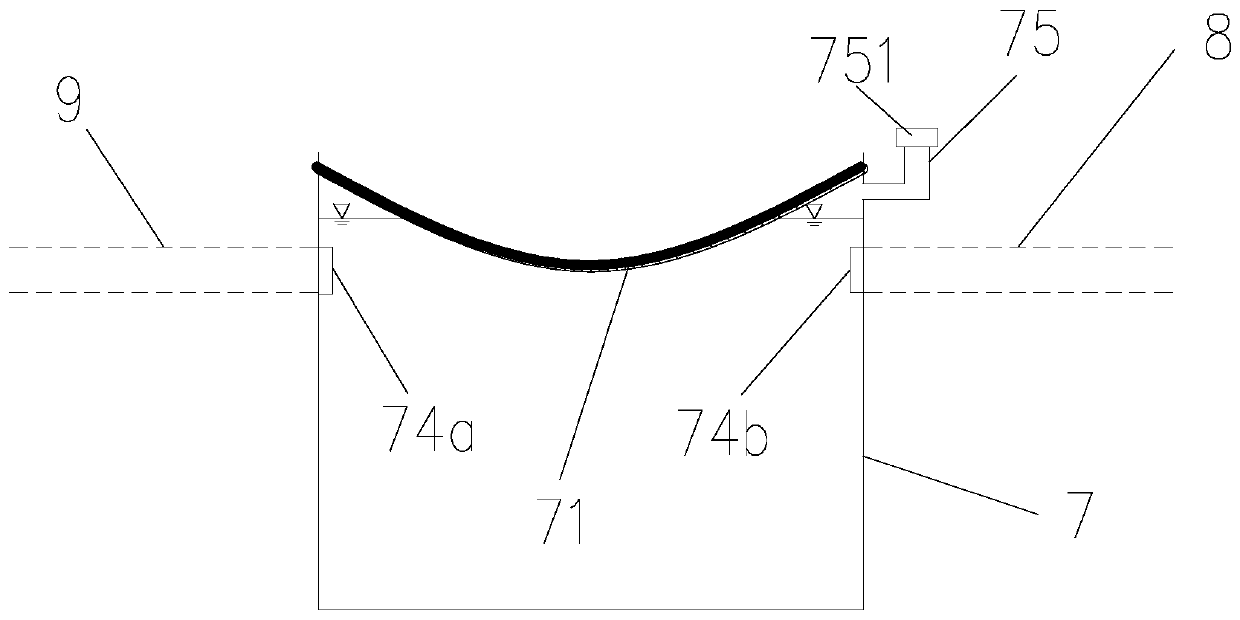

[0081] The water tank 7 is used to be arranged below the track surface of the tunnel 1 , and the top of the water tank 7 is provided with an elastic diaphragm 71 . Along the length direction of the tunnel 1, at least two water tanks 7 are arranged.

[0082] The water tank 7 is also provided with an adding port 75 which is detachably sealed by a sealing end cover 751 . The opening height of the adding port 75 is higher than the top surface of the water tank 7 .

[0083] A one-way valve 74a is provided in the water outlet pipe 9 , one end of the water outlet pipe 9 is connected to the water tank 7 , and the other end is used to connect the horizontal blind pipe 2 and / or the vertical dead pipe 3 in the tunnel 1 .

[0084] Further, a plurality of water outle...

Embodiment 2

[0096] see Figure 4 , the embodiment of the present invention provides a tunnel 1 drainage pipe crystallization prevention system, which differs from the tunnel 1 drainage pipe crystallization prevention system in Embodiment 1 in that: in this embodiment, the water tank 7 is also provided with a first grid Grid 72a and second grid 72b.

[0097] Specifically, the first grid 72a is arranged on the top of the water tank 7 and is fixedly connected with the water tank 7, the second grid 72b is arranged under the first grid 72a and is fixedly connected with the water tank 7, the first grid 72a and the second An elastic diaphragm cavity 73 for accommodating the elastic diaphragm 71 is formed between the grids 72b. The elastic diaphragm 71 is installed in the elastic diaphragm cavity 73 .

[0098] Further, the second grid 72b is a concave spherical structure, which is used to better match the shape of the deformed elastic diaphragm 71 .

[0099] On the basis of the tunnel 1 draina...

Embodiment 3

[0103] see Figure 5 , the embodiment of the present invention provides a tunnel 1 drainage pipe crystallization prevention method, which is based on the tunnel 1 drainage pipe crystallization prevention system provided in embodiment 1 or embodiment 2, comprising the following steps:

[0104] Install the above-mentioned tunnel 1 drainage pipe crystallization prevention system in tunnel 1;

[0105] Add acidic solute and / or solution in water tank 7;

[0106] After the operation of the tunnel 1, the piston wind generated by the train passing through the tunnel 1 and / or the natural wind in the tunnel 1 drives the elastic diaphragm 71 in the drainage pipe crystallization prevention and control system of the tunnel 1 to move downward, so that the water in the water tank 7 The acidic solution is discharged to the horizontal blind pipe 2 and / or the vertical blind pipe 3 through the outlet pipe 9;

[0107] Detect the liquid flowing into the side ditch 5 from the vertical dead leg 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com