Novel pressure blocking device for underground pressurized operation

A technology of operation end and operation tools, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., and can solve the problems of time-consuming, wasteful, and loss of profits in the plugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

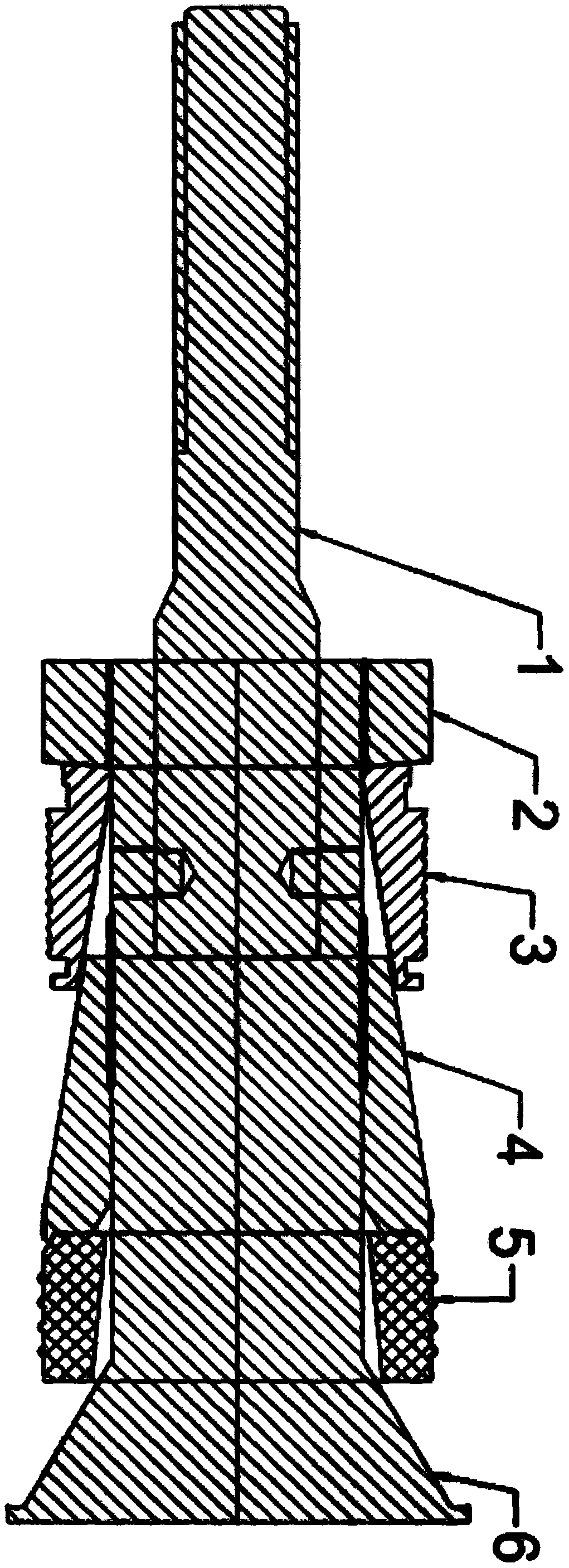

[0018] Such as figure 1 As shown in , the pressure blocking device is composed of six parts: 1 tension rod, 2 push rings, 3 slips, 4 cones, 5 expansion rings, 6 center tube.

Embodiment 2

[0020] Install the plugging device on the tool string, transport it to the plugging position through the tool string, apply pressure to the plugging device to fix the slips on the casing wall, and the cone squeezes the expansion ring on the central tube to make it expand to Greater than or equal to the inner wall of the casing to achieve the plugging effect.

Embodiment 3

[0022] After the maintenance work is completed, pressurize the upper part of the pressure blocking device to separate the central pipe from the pressure blocking device, realize the disassembly of the device, achieve the effect of blocking, and resume normal construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com