Earth ramming vehicle capable of pre-cleaning for civil engineering

A technology of civil engineering and ramming vehicles, which is applied to road cleaning, cleaning methods, roads, etc., can solve problems such as inconvenient, troublesome, and insufficient ramming strength, and achieve good use effect, good cleaning effect, and large coverage area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

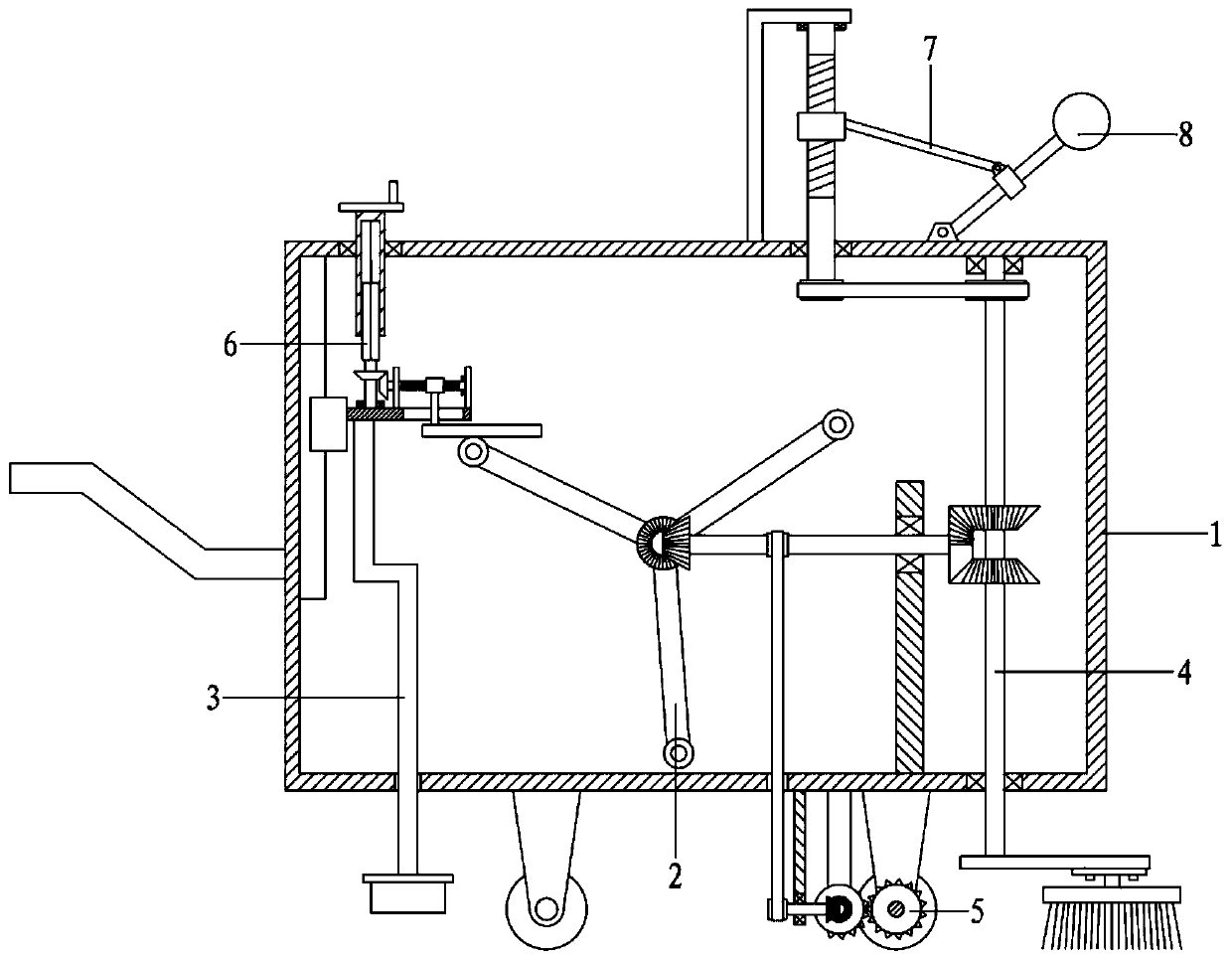

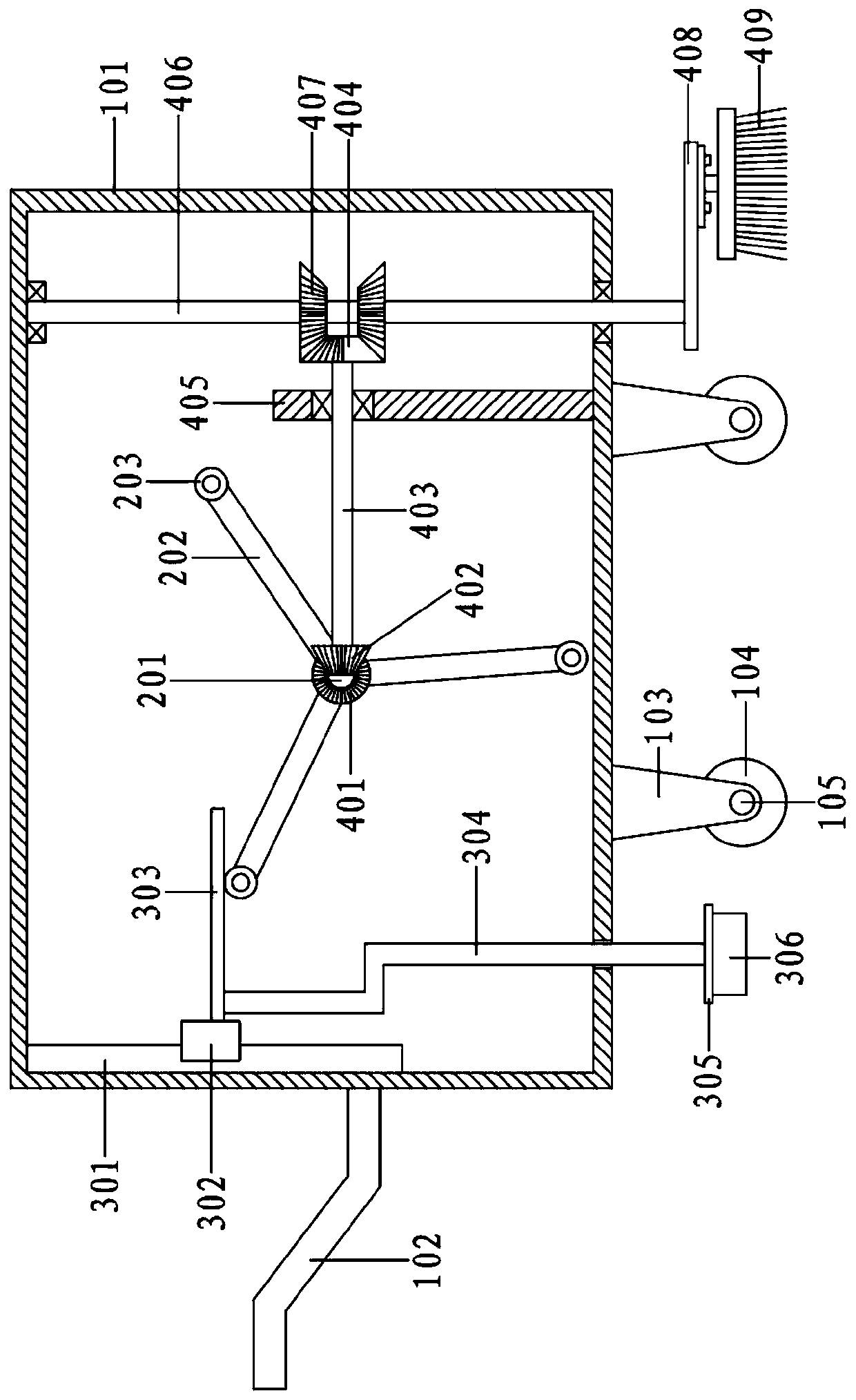

[0053] With reference to the accompanying drawings, a ground ramming vehicle for civil engineering capable of pre-cleaning includes a vehicle body assembly 1, a power assembly 2, a ramming assembly 3, and a cleaning assembly 4; the vehicle body assembly 1 includes a carriage 101, a handle 102, and a wheel frame 103 and wheels 104, the left side of the carriage 101 is connected with a handle 102, and the bottom of the carriage 101 is connected with a wheel 104 through a wheel frame 103; the power assembly 2 is arranged in the middle of the carriage 101; the ramming assembly 3 is arranged on the left side of the power assembly 2, and the ramming assembly 3. The bottom end extends out of the carriage 101 and is provided with a tamping block 306; the cleaning assembly 4 is arranged on the right side of the power assembly 2, and the bottom end of the cleaning assembly 4 also extends out of the carriage 101 and is provided with a broom 409.

Embodiment 2

[0055] With reference to the accompanying drawings, a ground ramming vehicle for civil engineering capable of pre-cleaning includes a vehicle body assembly 1, a power assembly 2, a ramming assembly 3, and a cleaning assembly 4; the vehicle body assembly 1 includes a carriage 101, a handle 102, and a wheel frame 103 and wheels 104, the left side of the carriage 101 is connected with a handle 102, and the bottom of the carriage 101 is connected with a wheel 104 through a wheel frame 103; the power assembly 2 is arranged in the middle of the carriage 101; the ramming assembly 3 is arranged on the left side of the power assembly 2, and the ramming assembly 3. The bottom end extends out of the carriage 101 and is provided with a tamping block 306; the cleaning assembly 4 is arranged on the right side of the power assembly 2, and the bottom end of the cleaning assembly 4 also extends out of the carriage 101 and is provided with a broom 409.

[0056] Wherein, the power assembly 2 incl...

Embodiment 3

[0065] The difference from Embodiment 2 is that the strength of the ground tamping in this embodiment can be adjusted.

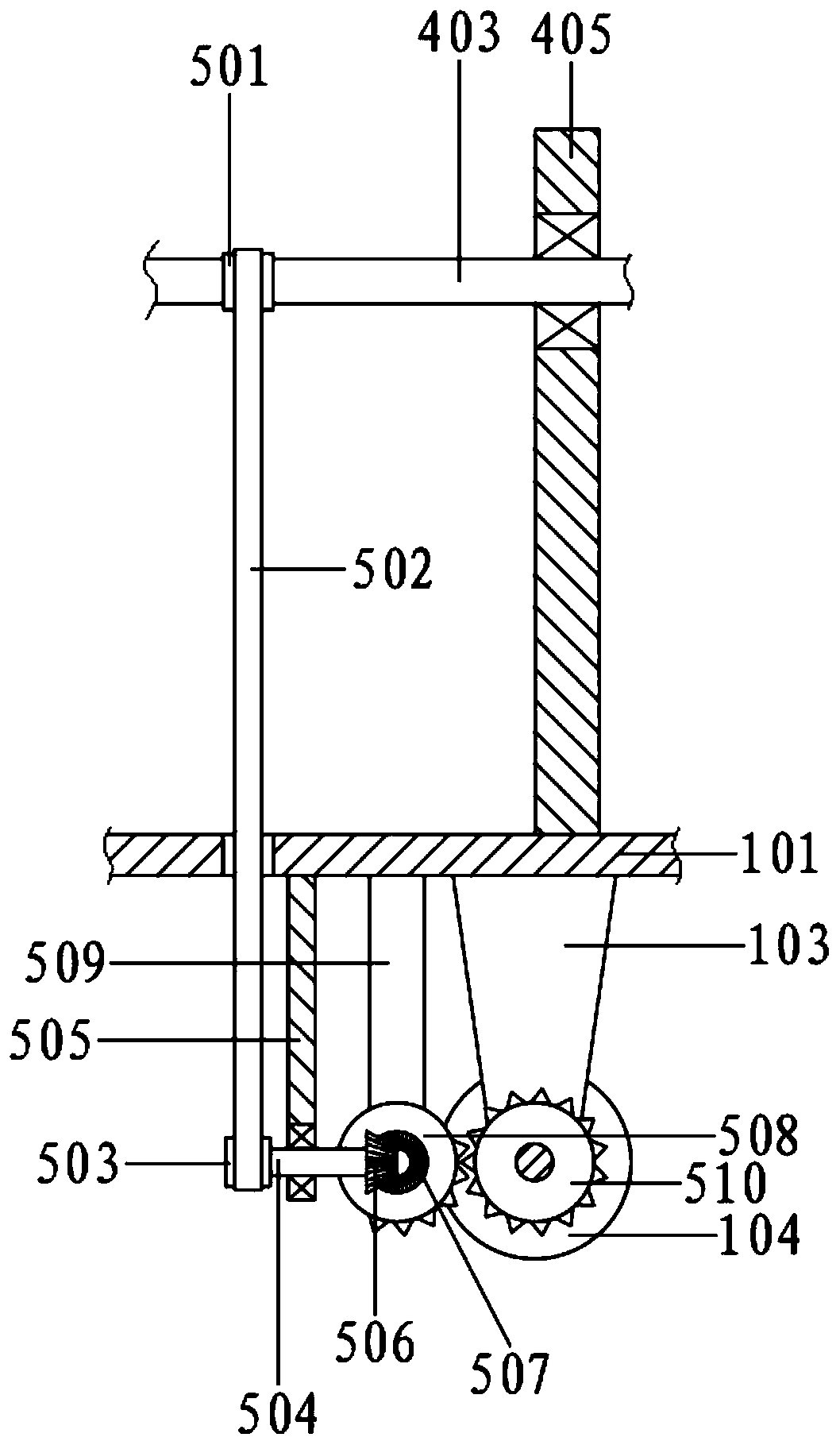

[0066] It also includes an adjustment assembly 6; the adjustment assembly 6 is arranged on the right side of the No. 1 slider 302, including a hand wheel 601, a hollow shaft 602, a special-shaped shaft 603, a circular shaft 604, a No. 5 bevel gear 605, a No. 6 bevel gear 606, and a No. 4 bevel gear. Rotating shaft 607, fixed plate 608, No. 1 moving nut 609, No. 2 connecting rod 610 and moving plate 611;

[0067] The left end of the moving plate 611 is fixedly connected to the No. 1 slider 302, and the right section of the moving plate 611 is opened with a straight groove; the baffle plate 303 is set under the moving plate 611; the hollow shaft 602 is set above the moving plate 611, and the hollow shaft 602 penetrates and passes through The bearing rotates and connects the top plate of the compartment 101, and the top of the hollow shaft 602 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com