Microwave absorbent and preparation method thereof

A microwave absorbent and solvent technology, applied in the field of microwave absorbent and its preparation, can solve the problems affecting soil remediation and use, poor stability of microwave absorbent, etc. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

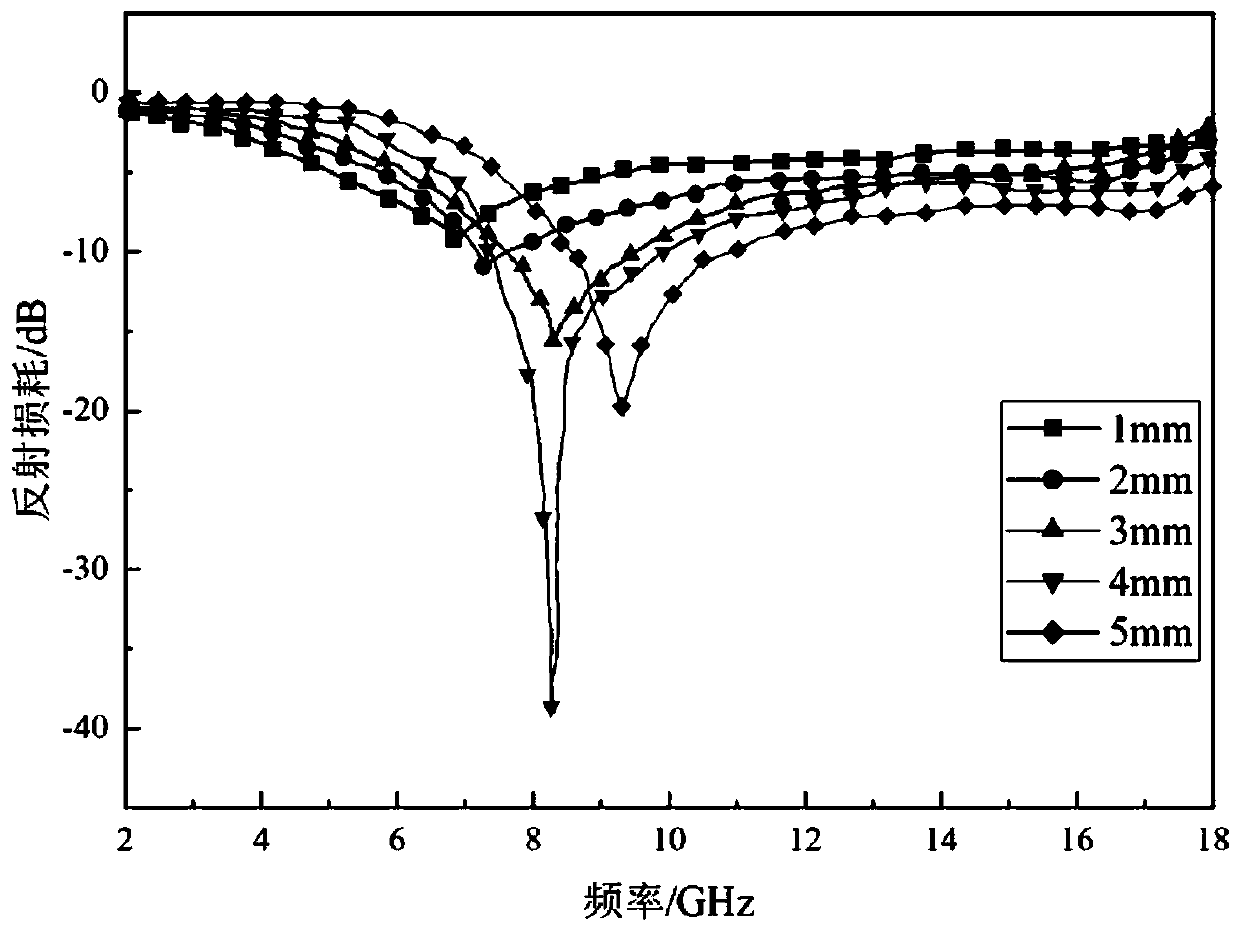

Image

Examples

Embodiment 1

[0031] The invention provides a microwave absorber, which comprises the following components in parts by weight: attapulgite: 40 parts, nano titanium dioxide: 15 parts, ferrite: 25 parts, Fe 3 (CO) 12 : 20 parts, ethanol: 60 parts, α-ketoglutarate: 12 parts, Co(CO) 3 H: 8 parts and Sb 2 o 3 : 8 servings.

[0032] The preparation method of above-mentioned microwave absorber, comprises the following steps:

[0033] Step a, weighing each component according to the above-mentioned raw material ratio;

[0034] Step b, the attapulgite, nano-titanium dioxide, ferrite, α-ketoglutaric acid, Co(CO) 3 H and Sb 2 o 3 Mix well, and then mix the obtained mixture with Fe 3 (CO) 12 Add to ethanol and soak for 8h, filter, and the solid material filtered out is the pretreatment material;

[0035] Step c. Cool the pretreated material at 100° C. for 3 hours at a rate of 10° C. / h to 20° C. and let it stand for 9 hours to obtain the microwave absorber.

Embodiment 2

[0037] The invention provides a microwave absorber, which comprises the following components in parts by weight: attapulgite: 35 parts, nano-titanium dioxide: 10 parts, ferrite: 20 parts, Fe 3 (CO) 12 : 15 parts, ethanol: 65 parts, α-ketoglutarate: 13 parts, Co(CO) 3 H: 10 parts and Sb 2 o 3 : 10 servings.

[0038] The preparation method of above-mentioned microwave absorber, comprises the following steps:

[0039] Step a, weighing each component according to the above-mentioned raw material ratio;

[0040] Step b, the attapulgite, nano-titanium dioxide, ferrite, α-ketoglutaric acid, Co(CO) 3 H and Sb 2 o 3 Mix well, and then mix the obtained mixture with Fe 3 (CO) 12 Add to ethanol and soak for 5h, filter, and the solid material filtered out is the pretreatment material;

[0041] Step c. Cool the pretreated material at 90° C. for 4 hours to 21° C. at a rate of 14° C. / h, and let it stand for 8 hours to obtain the microwave absorber.

Embodiment 3

[0043] The invention provides a microwave absorber, which comprises the following components in parts by weight: attapulgite: 45 parts, nano-titanium dioxide: 17 parts, ferrite: 30 parts, Fe 3 (CO) 12 : 26 parts, ethanol: 55 parts, α-ketoglutarate: 10 parts, Co(CO) 3 H: 7 parts and Sb 2 o 3 : 7 servings.

[0044] The preparation method of above-mentioned microwave absorber, comprises the following steps:

[0045] Step a, weighing each component according to the above-mentioned raw material ratio;

[0046]Step b, the attapulgite, nano-titanium dioxide, ferrite, α-ketoglutaric acid, Co(CO) 3 H and Sb 2 o 3 Mix well, and then mix the obtained mixture with Fe 3 (CO) 12 Add to ethanol and soak for 10h, filter, and the solid material filtered out is the pretreatment material;

[0047] Step c. Cool the pretreated material at 110° C. for 2 hours at a rate of 12° C. / h to 22° C. and let it stand for 8 hours to obtain the microwave absorber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com