Side wall reinforcing plate assembly and vehicle with same

A reinforcement plate and assembly technology, applied in the connection between superstructure subassemblies, vehicle parts, superstructure subassemblies, etc., can solve the problems of increased weight and production cost, easy electrophoretic shielding, and force transmission effect change Poor and other problems, to achieve the effect of weight reduction, weight reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

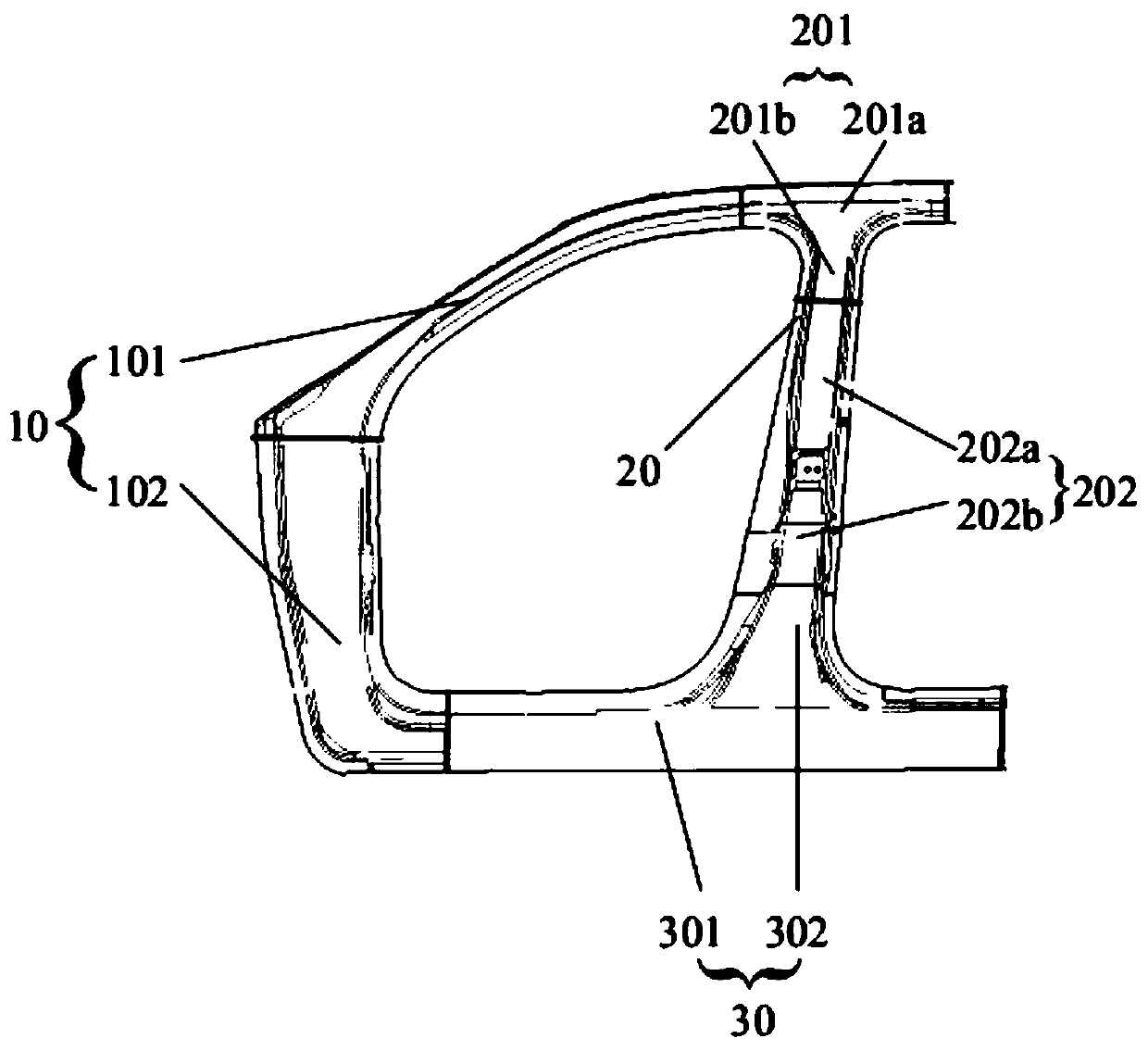

[0026] see figure 1 , figure 1 The side wall AB pillar reinforcement panel assembly provided for the present invention includes an A-pillar reinforcement panel 10 , a B-pillar reinforcement panel 20 , and a rocker reinforcement panel 30 .

[0027] The A-pillar reinforcement plate 10 includes an A-pillar upper reinforcement plate 101 and an A-pillar lower reinforcement plate 102. The A-pillar upper reinforcement plate 101 extends upward and obliquely from the front to the rear of the vehicle, and the A-pillar lower reinforcement plate 102 extends from the front to the rear of the vehicle first. Extending downward and horizontally backward, the lower end of the A-pillar upper reinforcing plate 101 is connected with the upper end of the A-pillar lower reinforcing plate 102 .

[0028] The B-pillar reinforcement plate 20 includes a B-pillar upper reinforcement plate 201 and a B-pillar lower reinforcement plate 202. The B-pillar upper reinforcement plate 201 is T-shaped and include...

Embodiment 2

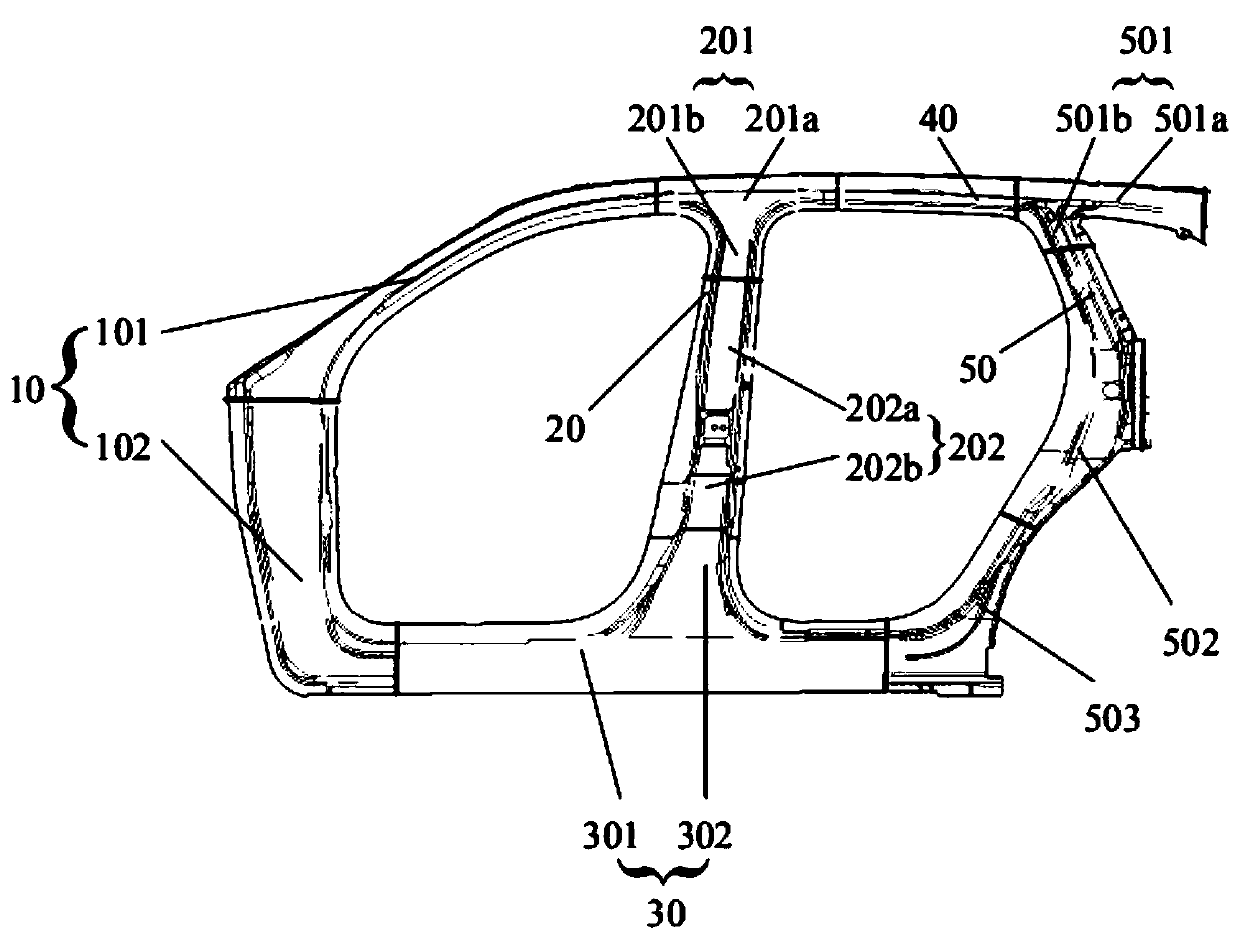

[0034] see figure 2 , figure 2 The side wall ABC pillar reinforcement plate assembly provided for the present invention is installed in a car with high safety requirements and intensive production requirements, and the side beam is added on the basis of the side wall AB pillar reinforcement plate assembly in Example 1 Reinforcement panel 40 and C-pillar reinforcement panel 50 .

[0035] The C-pillar reinforcement plate 50 includes a C-pillar upper reinforcement plate 501, a lock reinforcement plate 502, and a C-pillar lower reinforcement plate 503. The C-pillar upper reinforcement plate 501 includes a fifth connecting plate 501a extending from the front to the rear and connecting with the fifth The connecting plate 501a is connected to the sixth connecting plate 501b extending toward the bottom of the vehicle. The sixth connecting plate 501b is connected to the front end side of the fifth connecting plate 501a. The fifth connecting plate 501a is the upper end of the C-pilla...

Embodiment 3

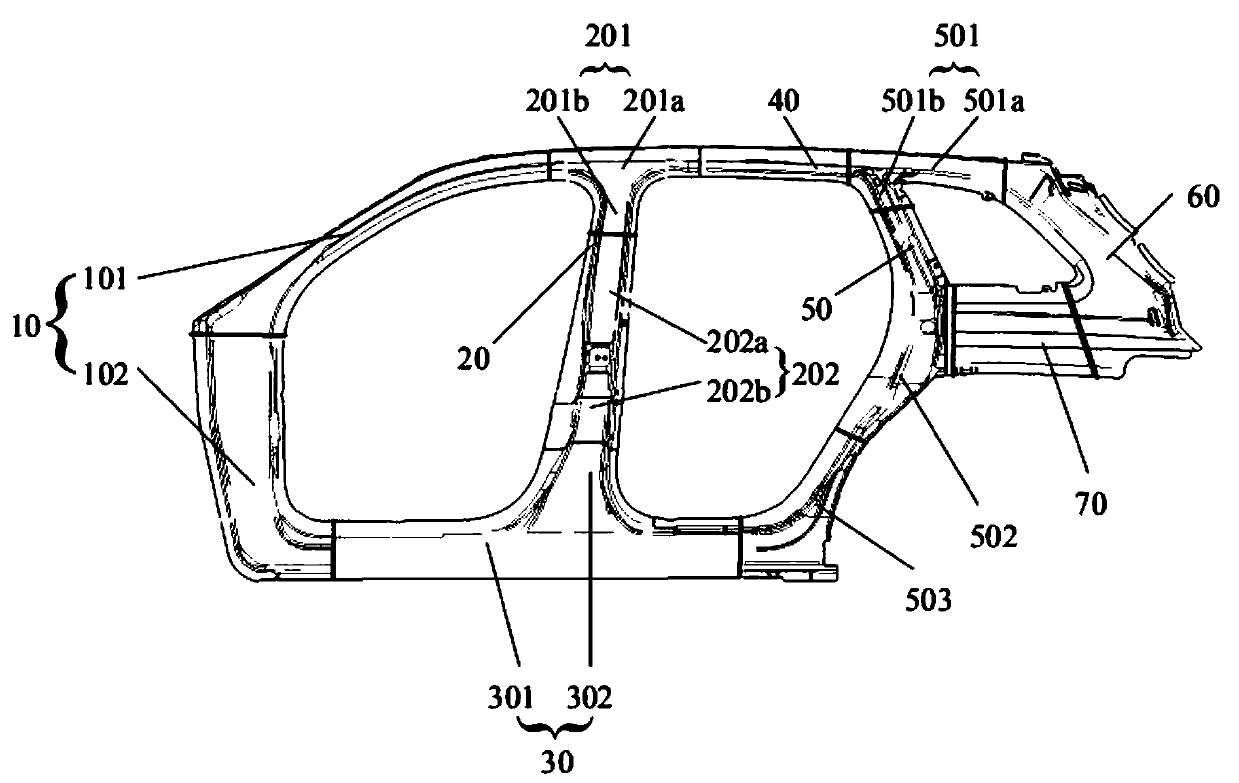

[0038] see image 3 , image 3 The side wall ABCD pillar reinforcement plate assembly provided for the present invention is installed in automobiles with higher safety requirements and higher intensive production requirements, and the D-pillar reinforcement plate is added on the basis of the side wall ABC pillar reinforcement plate in Example 2 60 and CD column reinforcement plate connecting plate 70.

[0039] When manufacturing the ABCD pillar reinforcement plate assembly of the side wall, the joint of the A-pillar upper reinforcement plate 101 and the A-pillar lower reinforcement plate 102 is laser tailor-welded, and the junction of the B-pillar upper reinforcement plate 201, the hard area 202a, and the transition area 202b is laser welded. Welding, C-pillar upper reinforcement plate 501, lock reinforcement plate 502, and C-pillar lower reinforcement plate 503 joint laser tailor welding, the upper end of A-pillar upper reinforcement plate 101 and the first connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com