Tool quick replacing system for production line of 5G large die castings

A die-casting and production line technology, applied in the field of tooling quick change system, can solve the problems of difficult on-site management, low safety, large work site, etc., and achieve the effect of convenient on-site management, ensuring safety, and small work site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

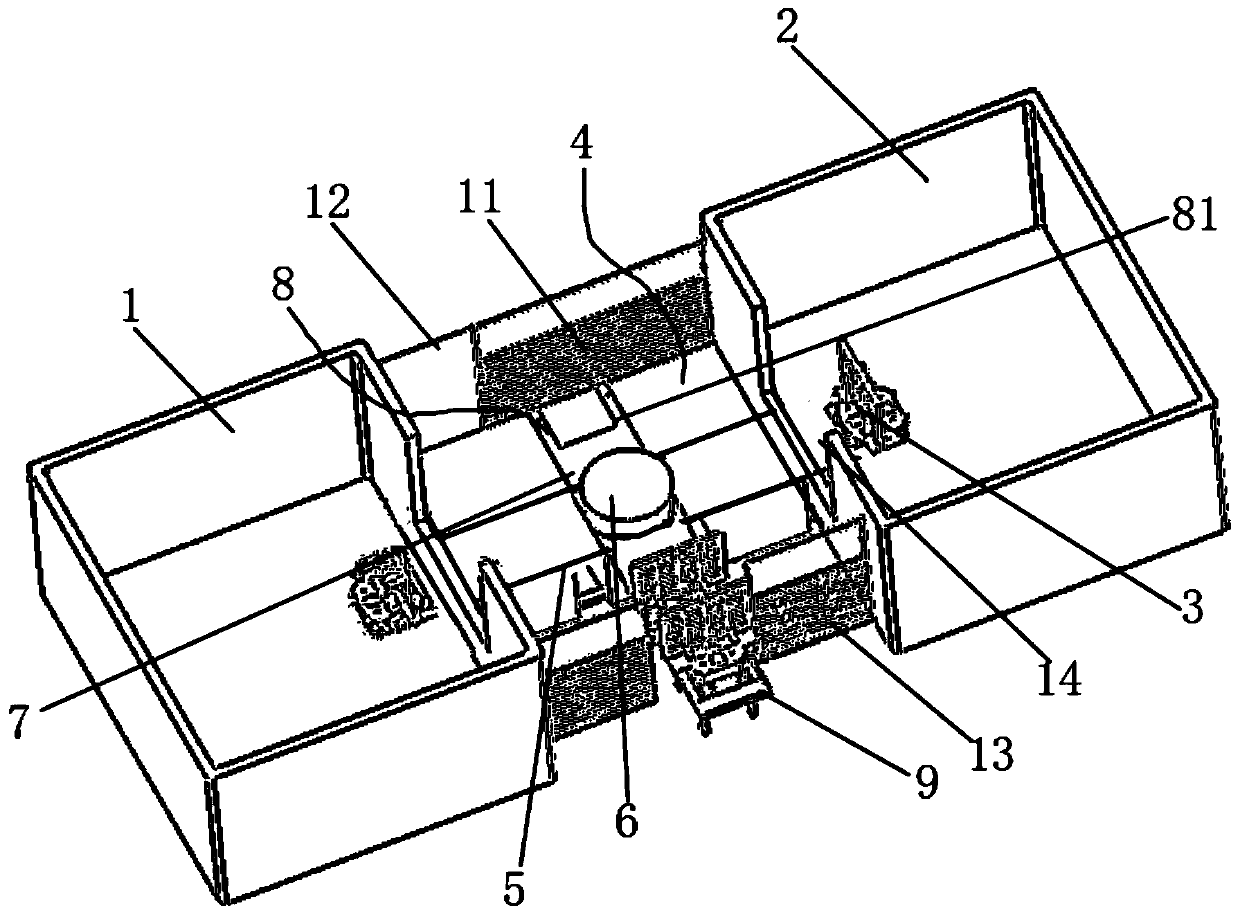

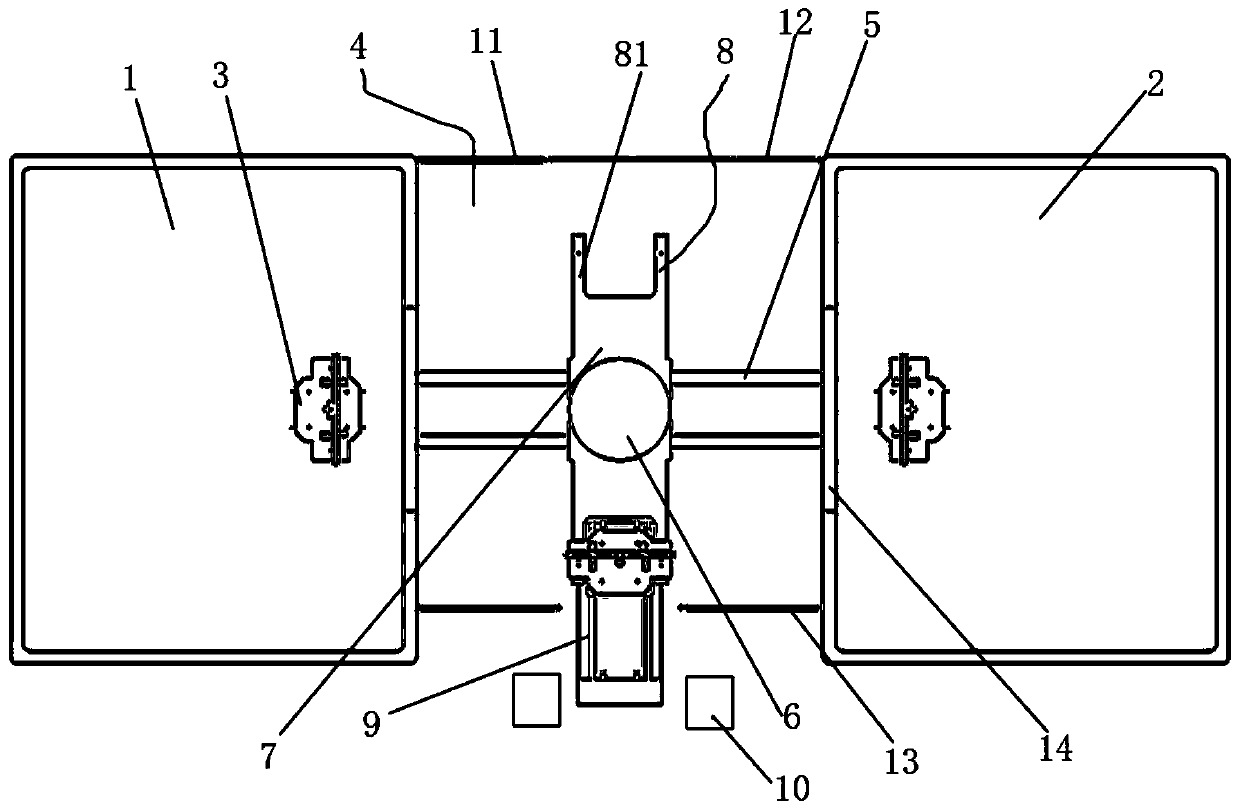

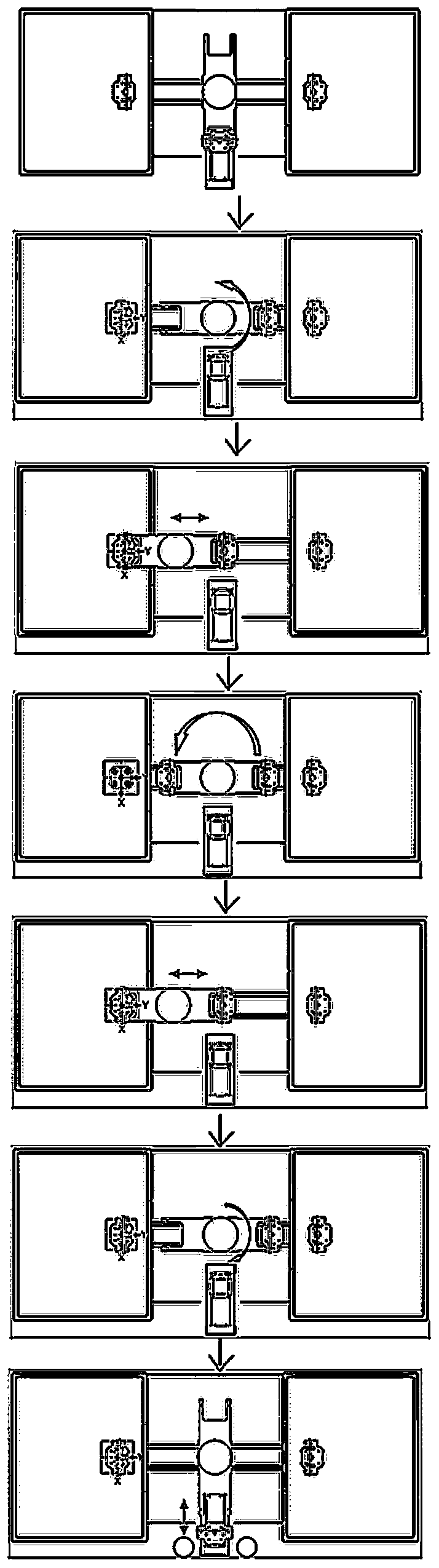

[0018] Tooling quick change system for the production line of 5G large die castings, see Figure 1-Figure 3 : It includes two adjacently arranged machines, specifically the first machine 1 and the second machine 2, each machine is equipped with a corresponding tooling 3, and there is a quick-change interval space 4 between the two machines , a transverse rail 5 is arranged in the quick-change interval space 4, and the two ends of the length direction of the transverse rail 5 are respectively arranged towards the position of the tooling and fixture of the corresponding machine table, and a sliding seat (covered, not shown in the figure) is arranged on the transverse rail 5 , a turntable 6 is integrated on the sliding seat, a linear support arm 7 is arranged on the turntable 6, transfer mechanisms 8 are respectively arranged at both ends of the linear support arm 7 in the length direction, and the center position in the length direction of the linear support arm 7 is arranged cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com