Automatic cooker

A cooking machine and rough surface technology, which is applied in the field of cooking machines, can solve the problems of limited heating area of aluminum foil boxes, complex structure of the whole machine, and limited number of ribs, etc., so as to avoid insufficient mixing of stir-frying, improve the mixing effect of stir-frying, The effect of contact area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

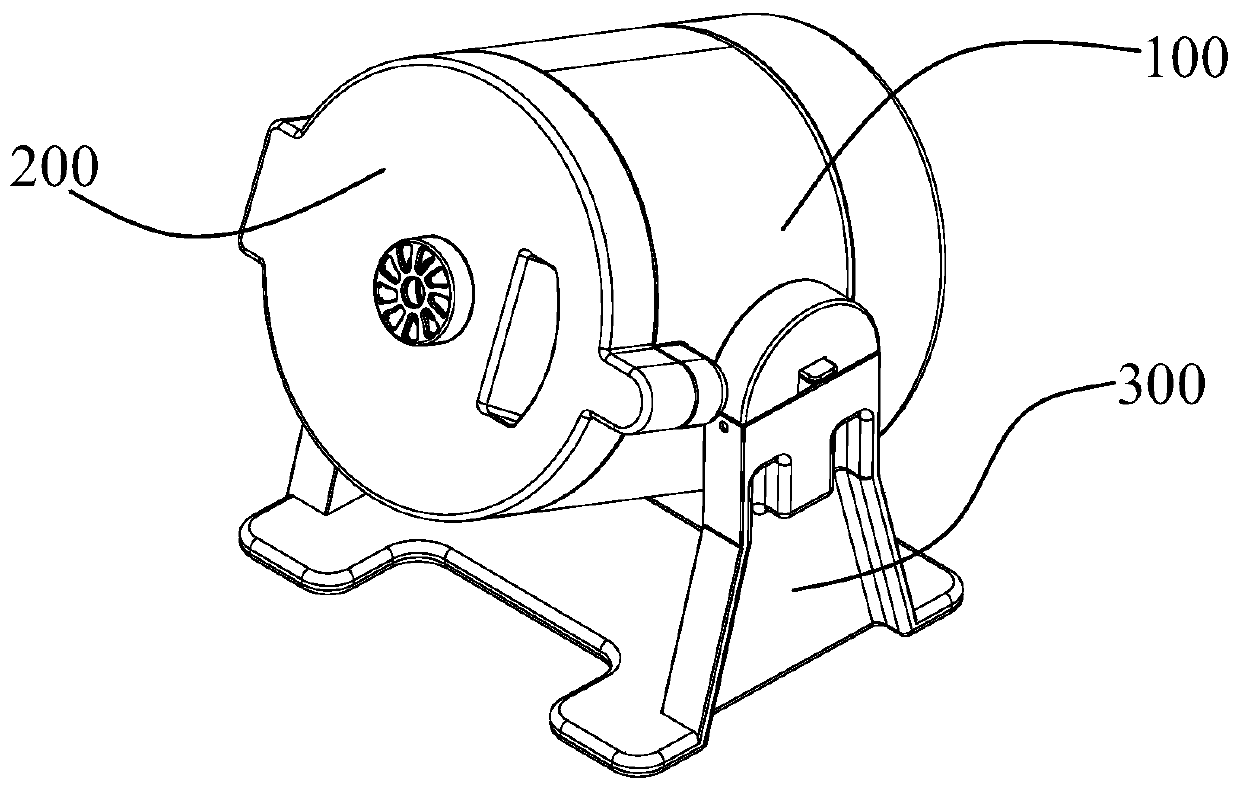

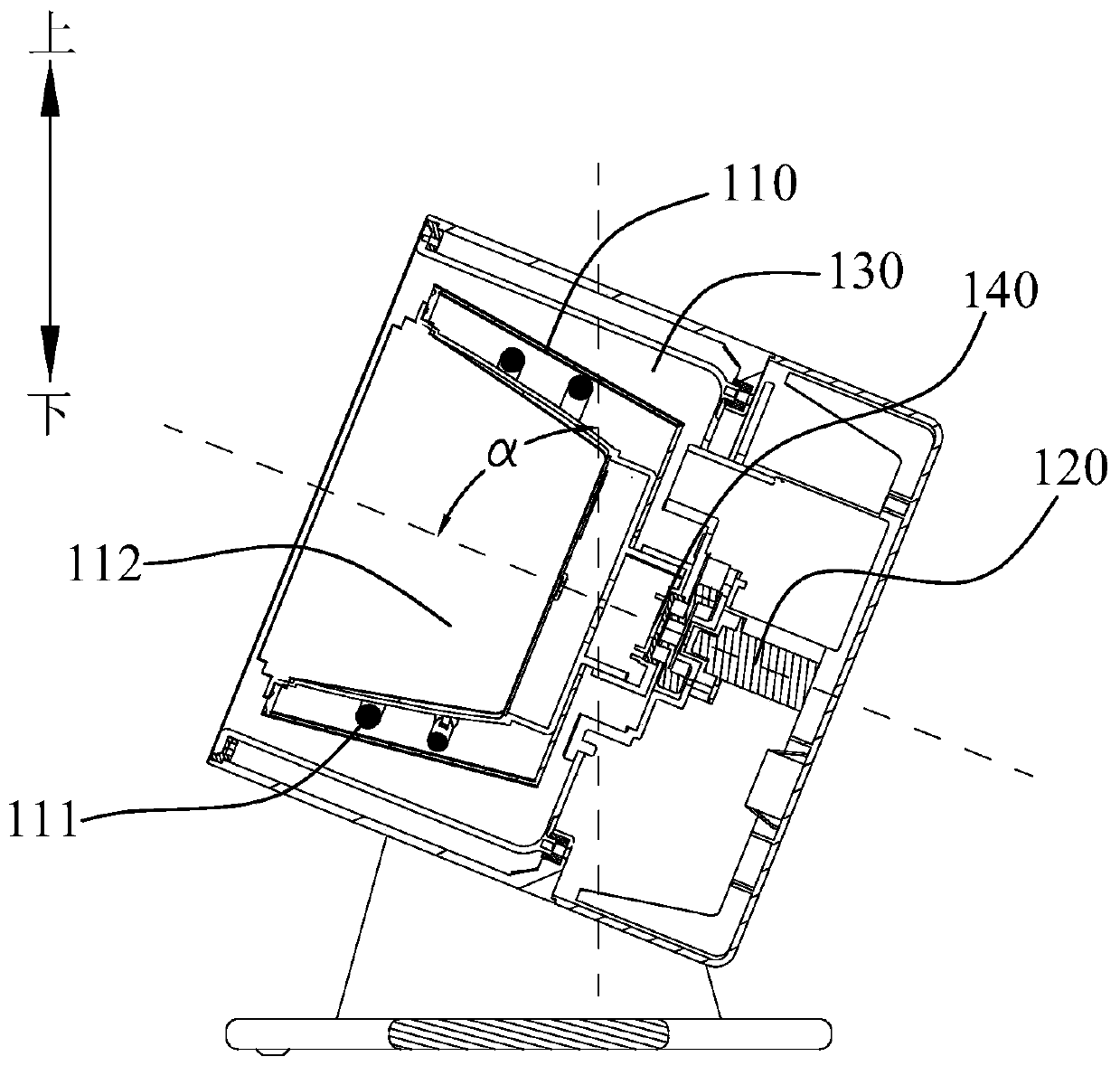

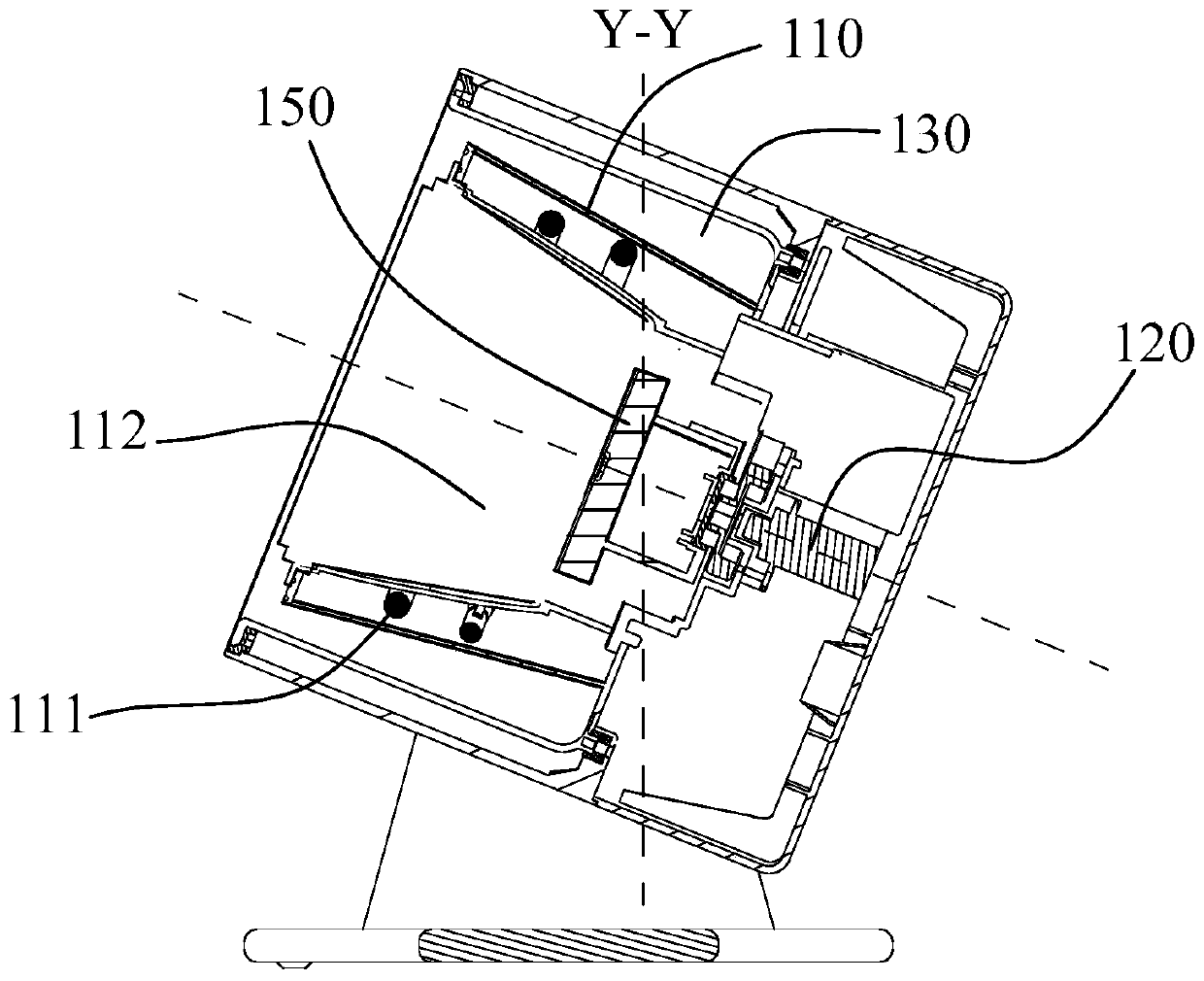

[0051] A kind of cooking machine is provided in the present embodiment, such as figure 1 , 2 As shown, the cooking machine includes a body 100, a cover 200 and a frame 300, the cover 200 is hinged to the body 100, the body is arranged on the frame 300, the body 100 includes a heating cavity 110, The motor 120 and the movable chamber 130, the heating chamber 110 is provided with a heating device 111 and a heating chamber 112 for accommodating the aluminum foil box, the motor 120 is connected with the heating chamber 110 through a connecting device 140, and the motor drives the heating The cavity 110 rotates in the movable cavity 130 of the body. When cooking is required, install the aluminum foil box containing the ingredients in the heating cavity 112 and cover the machine cover, start the heating device 111 to heat the aluminum foil box in the heating cavity 112, driven by the motor 120, The heating cavity 110 drives the aluminum foil box to rotate so as to realize the rot...

Embodiment 2

[0057] This embodiment provides an aluminum foil box used in conjunction with the cooking machine in Embodiment 1. Such as Figure 4 As shown, the aluminum foil box includes a box body 1100 and a cover body 1200. The box body 1100 includes a bottom wall 1110 and a side wall 1120. The bottom wall 1110 and the side wall 1120 form a cavity for dissolving ingredients and an opening 1130. The cover body 1200 is used to close the opening 1130 of the box body, and the inner surface 1121 of the side wall 1120 is provided with a stirring rough surface 1122 formed by folds, and the stirring rough surface 1122 drives the ingredients to stir fry with the rotation of the aluminum foil box.

[0058] Specifically, the folds may be formed during the pressing of the aluminum foil box, or may be pre-treated before pressing, or may be formed in other ways, so that the structure of the pressing mold is simple and the production is convenient.

[0059] It can be understood that the stirring roug...

Embodiment 3

[0096] The difference between this embodiment and the second embodiment is that the folds are only provided on the outer surface of the side wall of the aluminum foil box. Specifically, such as Figure 13 As shown, a heat-absorbing rough surface 1123 formed by wrinkles is provided on the outer surface of the side wall of the aluminum foil box, and the heat-absorbing rough surface 1123 absorbs heat to heat food.

[0097] It can be understood that the heat-absorbing rough surface may be partially disposed on the outer surface of the side wall, or may be disposed covering the outer surface of the side wall.

[0098] By setting the heat-absorbing rough surface formed by folds on the outer surface of the side wall of the box body, the surface area of the aluminum foil box body is increased. During the cooking process, the aluminum foil box body placed in the heating cavity of the cooking machine can absorb / store more The heat can be increased to speed up the cooking and improve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com