Biscuit finishing, pouring and scattering integrated production device

A technology for a production device and a material-spreading device, which is applied in the fields of dough processing, baked food processing, baking, etc., can solve the problems of unfavorable continuous production, inability to spread nut particles, high labor intensity of workers, etc., and achieves easy disassembly and transfer and The effect of transportation, improving operation fluency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

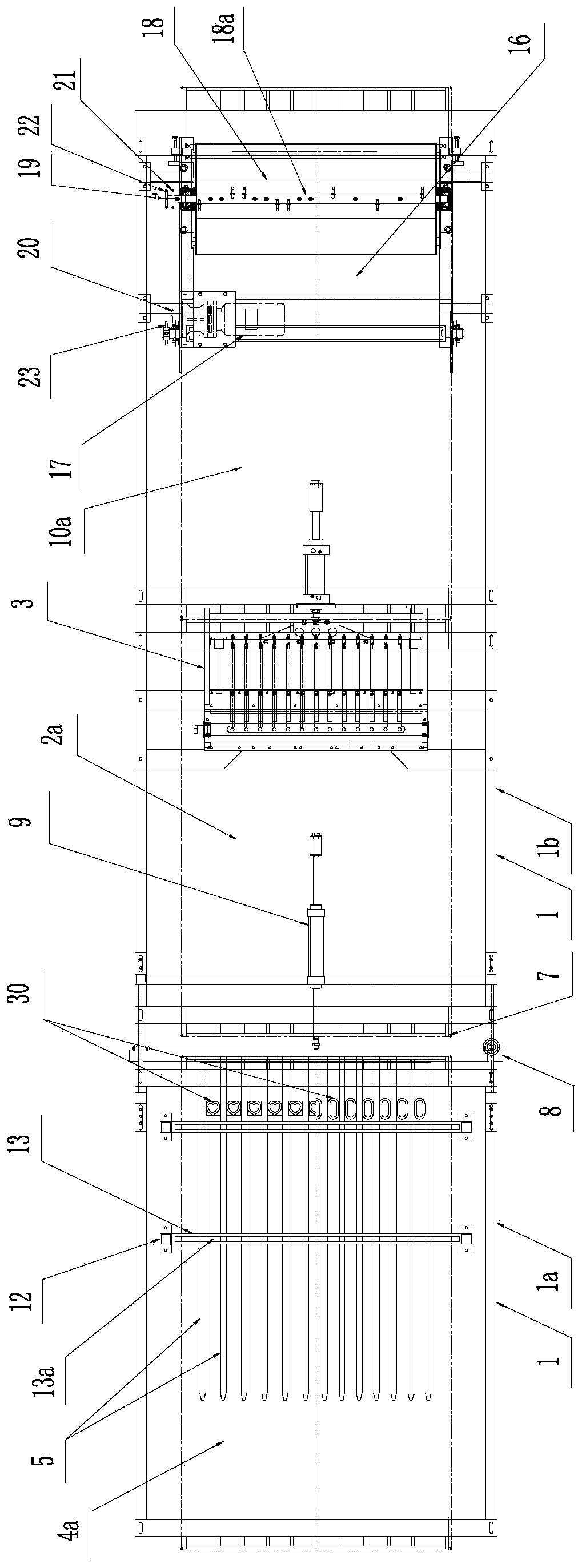

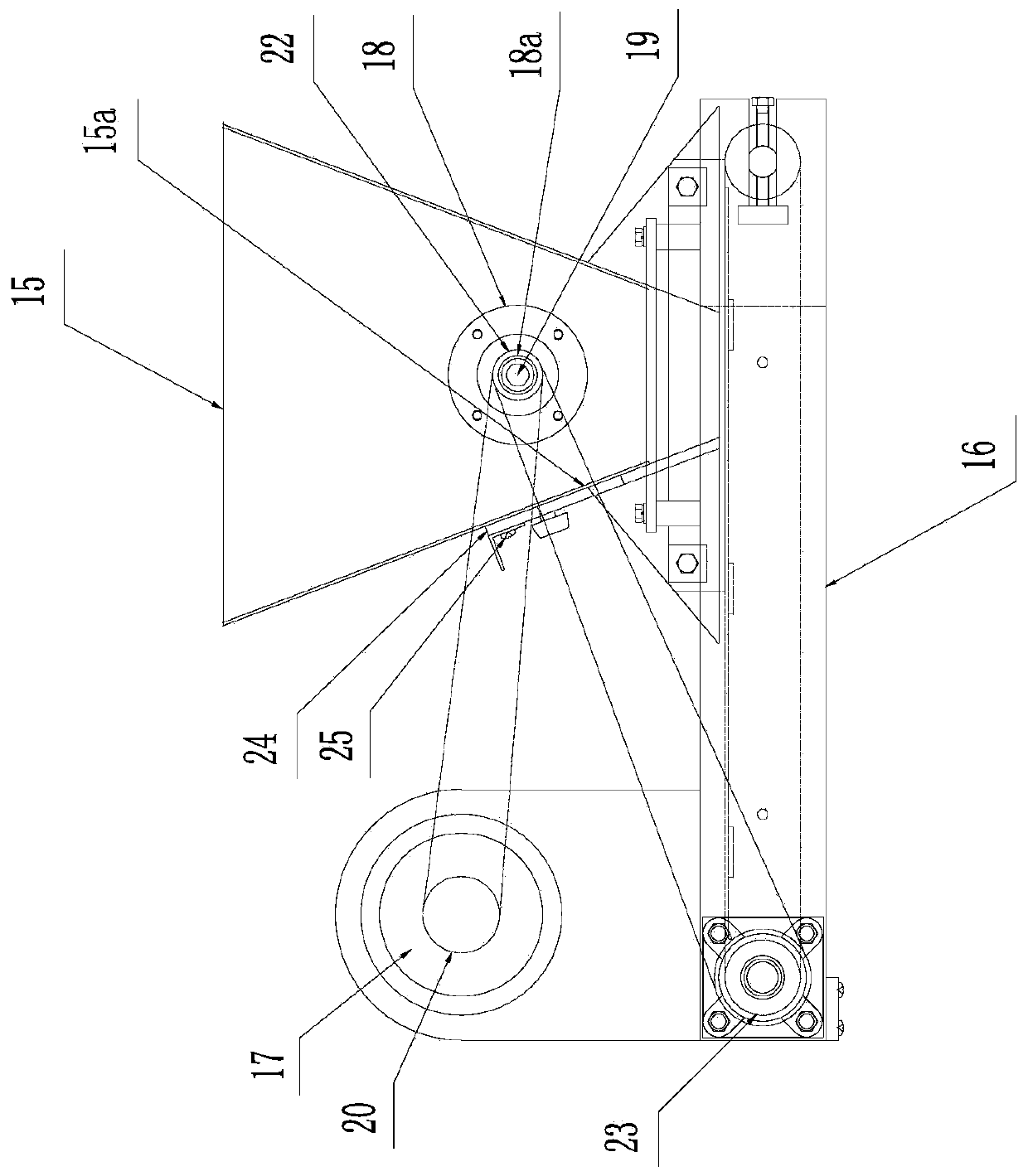

[0038] Example: Combine Figure 1~Figure 3 As shown, the specific implementation of the biscuit finishing, pouring and spreading integrated production device provided by the present invention is described as follows:

[0039] An integrated production device for finishing, pouring and spreading biscuits, which is designed with a frame 1, and this frame 1 is a split frame, consisting of a first frame 1a and a second frame assembled at the rear of the first frame 1a. The frames 1b are jointly formed, and the bottoms of the first frame 1a and the second frame 1b are both provided with rollers 29 . Wherein, the second frame 1b is provided with a conventional biscuit pouring mechanism, and this biscuit pouring mechanism is shared by the pouring belt conveyor 2 and the pouring machine 3 above the pouring conveyor belt 2a of the pouring belt conveyor 2. composition.

[0040] The core improvement solution of the present invention is that a biscuit sorting mechanism and a biscuit spre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com