A 3D printing system for cake decorating

A 3D printing and mounting technology, applied in the field of 3D printing, can solve the problems of simple modeling, time-consuming and laborious, limited cream cake, etc., achieve the effect of reducing skill requirements, avoiding mixed material printing, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

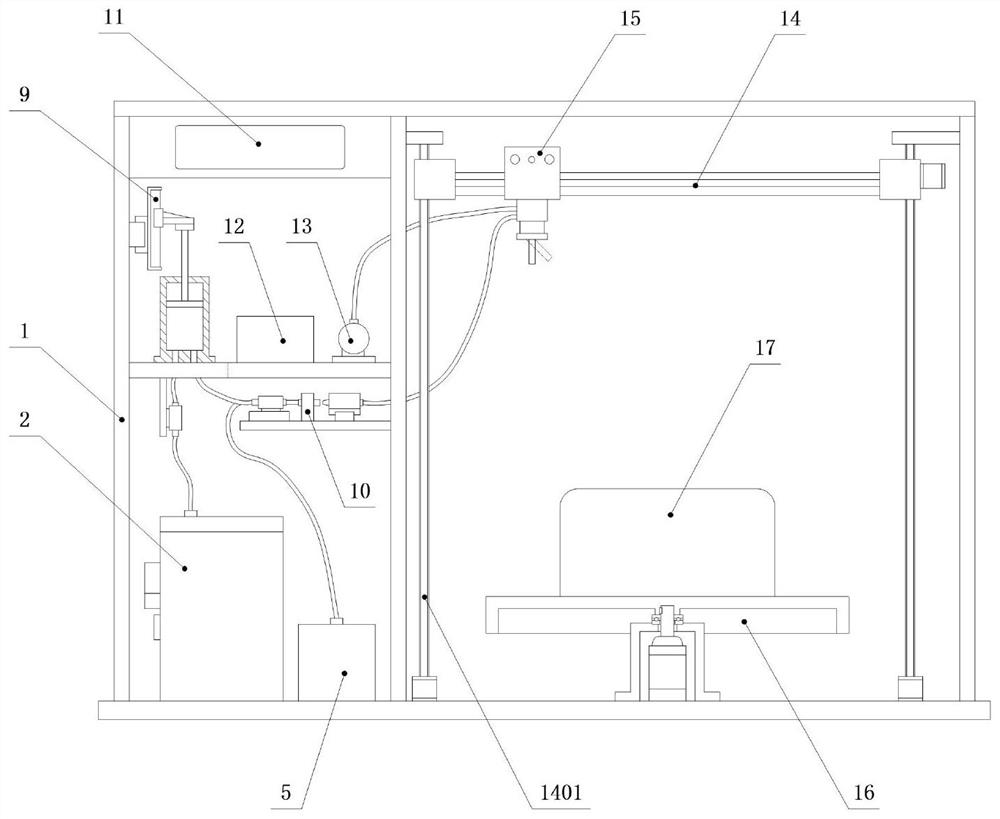

[0031] Such as figure 1 and figure 2 As shown, a cake decoration 3D printing system includes a frame 1, an operating device 11 is connected to the outside of the front panel of the frame 1, and an electromagnetic force device 9 is connected to the inside of the side panel of the frame 1; the inner cavity of the frame 1 is divided into a preparation cavity and print cavity;

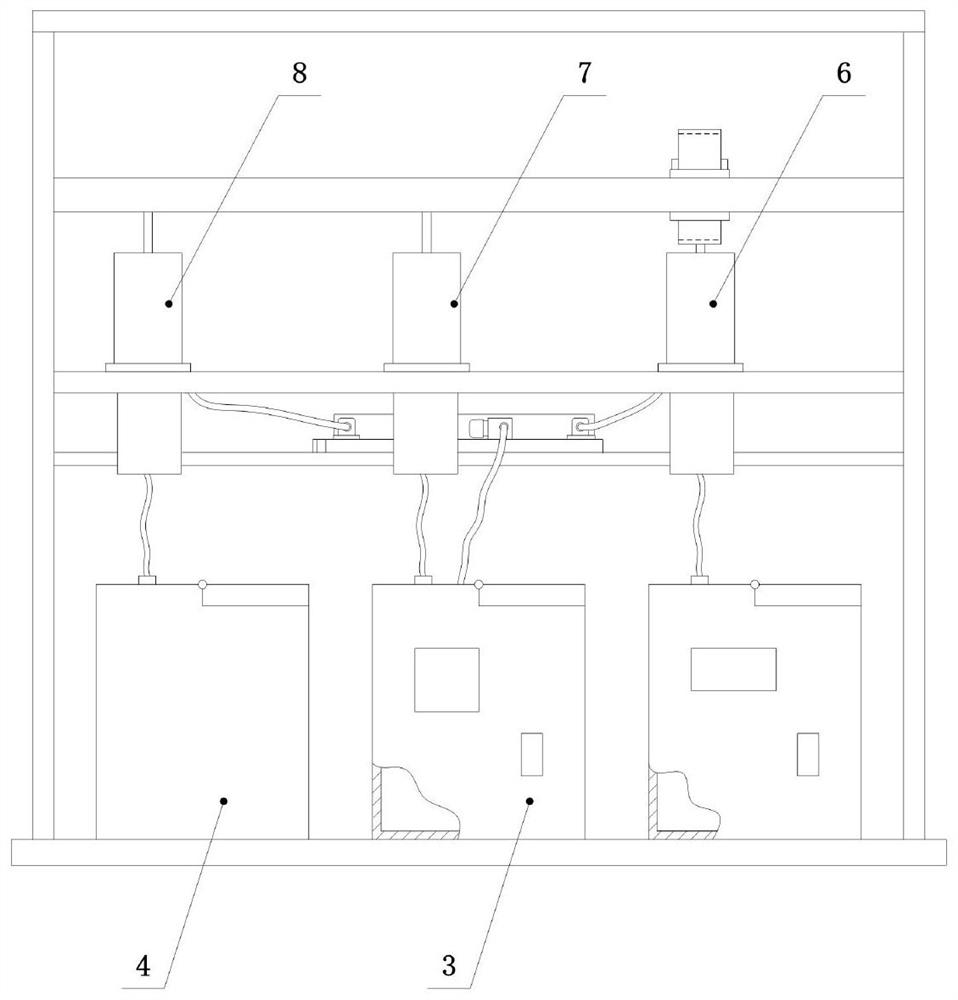

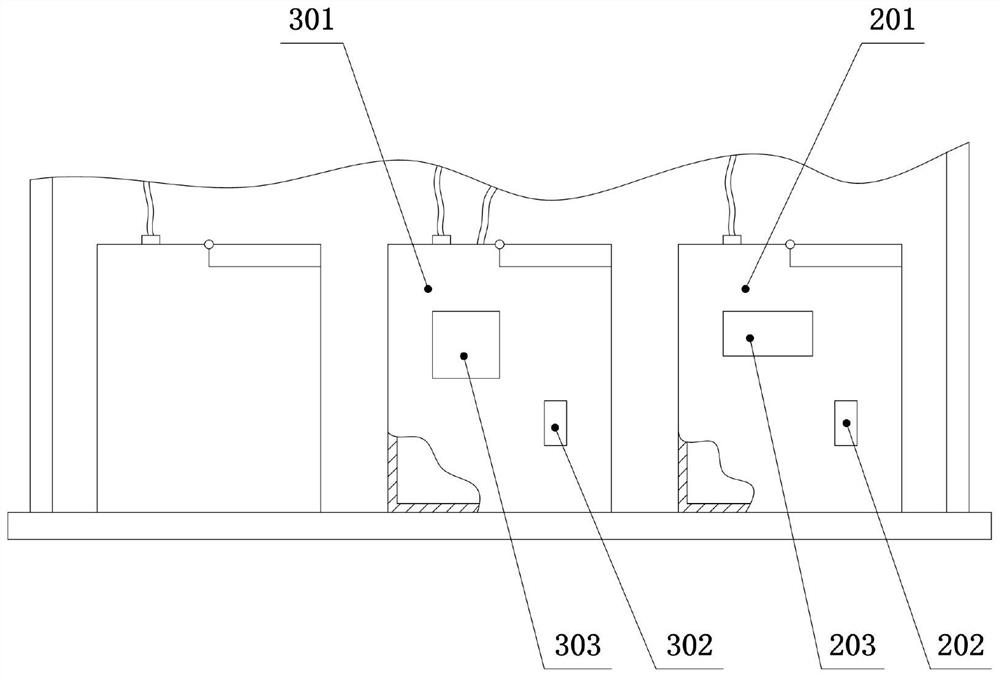

[0032] The preparation chamber is divided into upper, middle and lower layers. The frame 1 of the lower layer is connected with the low-temperature material box 2, the high-temperature material box 3, the normal temperature material box 4 and the absorption device 5, and the frame 1 of the middle layer is connected with the quick-connecting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com