A device for burying a drip irrigation belt on a seeder

A technology of drip irrigation belt and seeder, which is applied in the direction of seeder parts, sowing seeder, watering device, etc., can solve the problem that the crop growth does not achieve the expected effect, and achieve the reduction of filling work, good growth, sowing efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a device for burying a drip irrigation belt on a planter, and realizes the present invention through basic necessary technical features, so as to solve the problems raised in the technical background part of this application document.

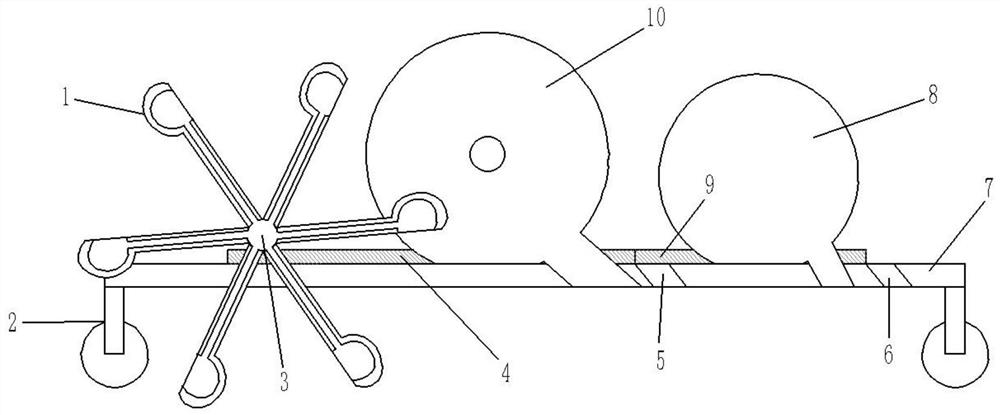

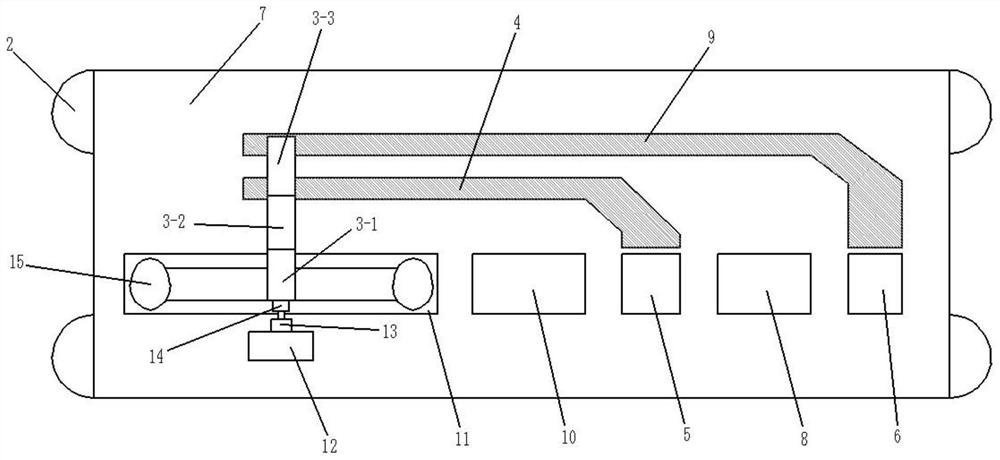

[0026] Specifically, as Figure 1-3 As shown, the embodiment of the present invention provides a device for burying a drip irrigation belt on a planter, including a workbench 7, and a support wheel 2 is provided on the left and right sides under the workbench 7, and the workbench 7 runs from left to right. There are excavation mechanism 1, buried belt mechanism 10 for releasing drip irrigation belt, first excavation port 5, seeding mechanism 8 for sowing seeds and second excavation port 6, excavation mechanism 1, buried belt mechanism 10, The first excavation port 5, the planting mechanism 8 and the second excavation port 6 are located on the same horizontal line. The left end of the worktable 7 is provided with ...

Embodiment 2

[0029] This example is based on Example 1 and optimizes the implementation in Example 1, so that this example is more stable during operation and has better performance, but it is not limited to the one described in this example. implementation.

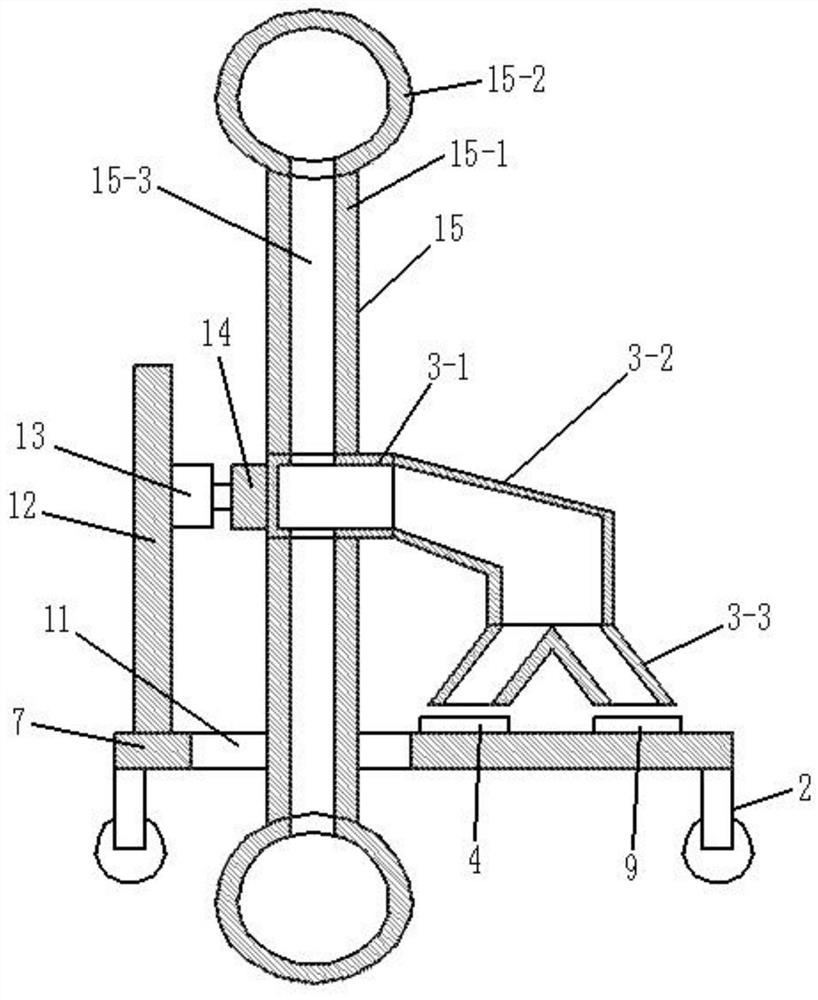

[0030] Specifically, in this embodiment, the soil dividing mechanism 3 includes a soil collecting cylinder 3-1 connected to the excavation end of the soil excavation mechanism 1, and the outlet end of the soil collecting cylinder 3-1 is connected to the soil collecting cylinder 3-1 through a connecting pipe 3-2. The soil distribution pipe 3-3 is connected, the soil distribution pipe 3-3 has two excavation openings, the bottom of the connecting pipe 3-2 is fixed with a support rod, and the bottom of the support rod is fixed on the workbench 7 .

[0031]The soil excavated by the excavation mechanism 1 enters the soil collecting cylinder 3-1 of the soil dividing mechanism 3. When the soil in the soil collecting cylinder 3-1 is checked o...

Embodiment 3

[0038] This example is based on Example 1 and optimizes the implementation in Example 1, so that this example is more stable during operation and has better performance, but it is not limited to the one described in this example. implementation.

[0039] Specifically, in this embodiment, the support wheel 2 on the right side of the workbench 7 is in the shape of a drum, and its length direction is consistent with the width direction of the workbench 7 , and the support wheel 2 on the right side of the workbench 7 is located at The right side of the second excavation port 6 .

[0040] The use of the drum-shaped support wheel 2 enables the soil on the seeds to be compacted when the soil is spread on the seeds at the second excavation port 6, so that there is no need to use a separate manual or mechanical device to compress the soil. Instead, with the movement of the workbench 7, the soil is automatically compacted.

[0041] In this embodiment, the shape of the cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com