Undertaking chassis of ramie harvester

A harvester and ramie technology, applied to the chassis of agricultural machinery, harvesters, balers, etc., can solve problems such as jamming, affecting service life, falling to the rear of the cutter mechanism or power walking mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

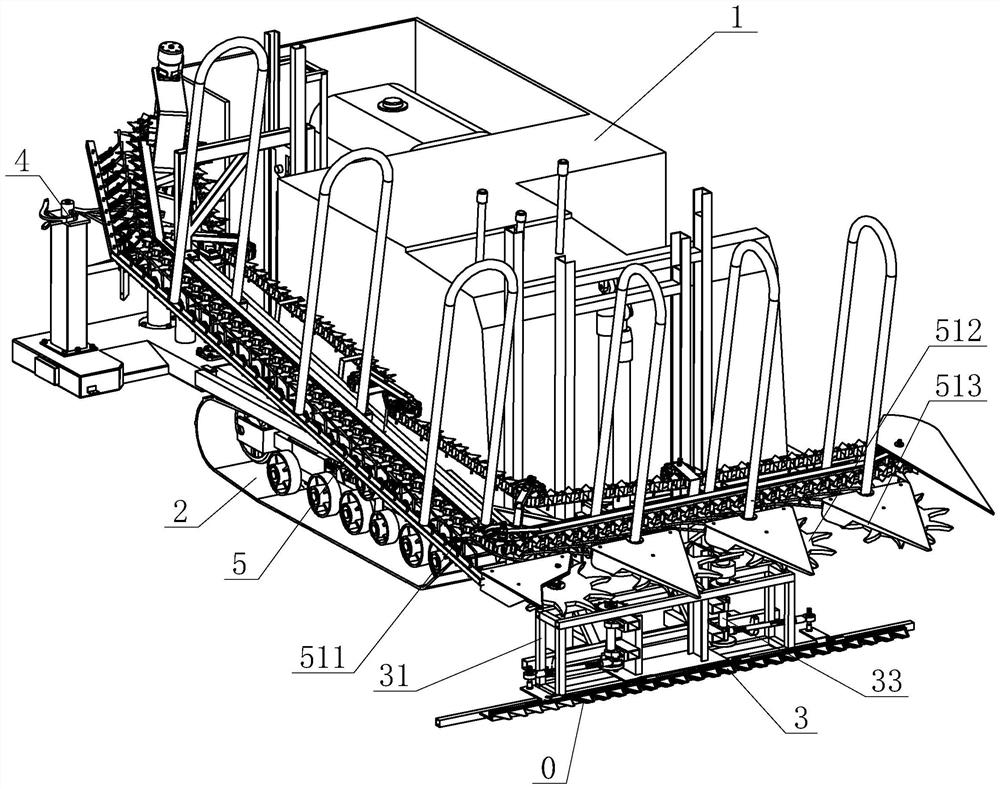

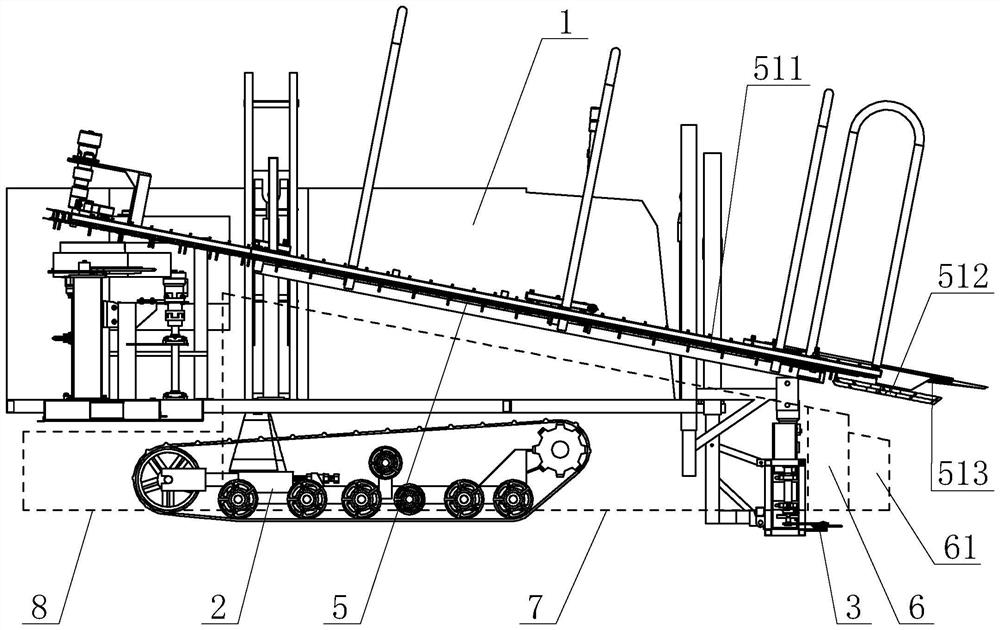

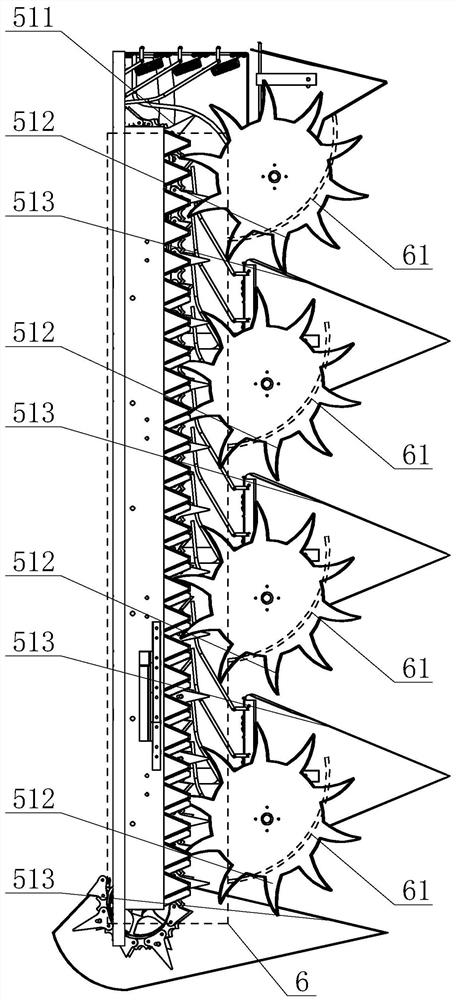

[0028] Such as Figure 1-10As shown, it is a specific embodiment of the receiving chassis of the ramie harvester of the present invention, including a fuselage 1 and a power walking mechanism 2 arranged at the bottom of the fuselage 1, and a cutter for cutting ramie rhizomes arranged in front of the fuselage 1 Mechanism 3, and being arranged on the fuselage 1 is used to collect the clamping and conveying mechanism 5 of the ramie that is cut by cutter mechanism 3, and is arranged on the fuselage 1 and is used for the bundling mechanism 4 that ramie is bundled, clamps and conveys The feeding end of mechanism 5 is positioned at the top of cutter mechanism 3, and bundling mechanism 4 is positioned at the discharge end of clamping conveying mechanism 5, and clamping conveying mechanism 5 comprises the conveying passage 511 that is used for conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com