Electric vehicle with battery free of disassembly and maintenance and battery maintenance system

A maintenance system and electric vehicle technology, applied in the field of electric vehicles, can solve the problems of battery performance degradation, high cost, and difficult design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

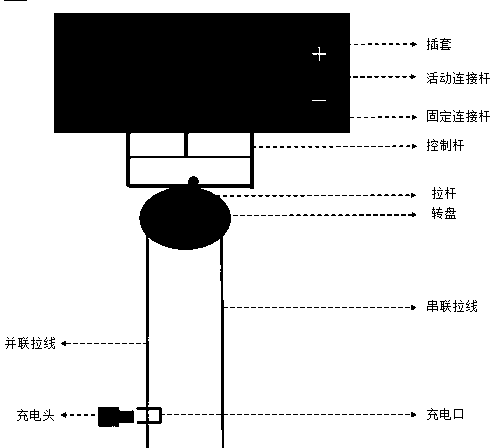

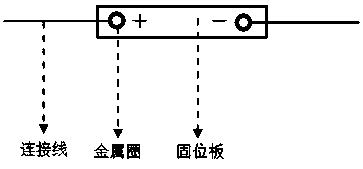

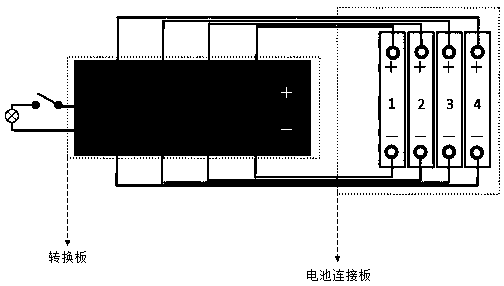

[0046] How the Transition Board works: Combining Figure 1-5 , the connection wires of the battery connection board are connected to the sockets with the same number according to the end numbers, the initial battery connection wires are connected in series, and the pull force is applied to the parallel wires, and the oval turntable connected with the parallel wires turns to the left, During the rotation of the turntable, the control rod is pushed in the direction of the socket, the fixed connecting rod fixed on the control rod is connected with the socket, and the tentacle of the control rod changes the movable connecting rod from oblique connection to straight connection (moving with the movable connecting rod The socket of the type connection is connected with the socket in the lower right corner, and is connected with the socket on the right side of the same line), and the battery connection plate is changed from series to parallel; the series cable is pulled, the turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com