Triangular prism processing technology

A technology of triangular prism and processing technology, applied in prisms, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as unsuitable processing of triangular prisms, and achieve the effect of reducing mutual contact, reducing damage caused by human factors, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

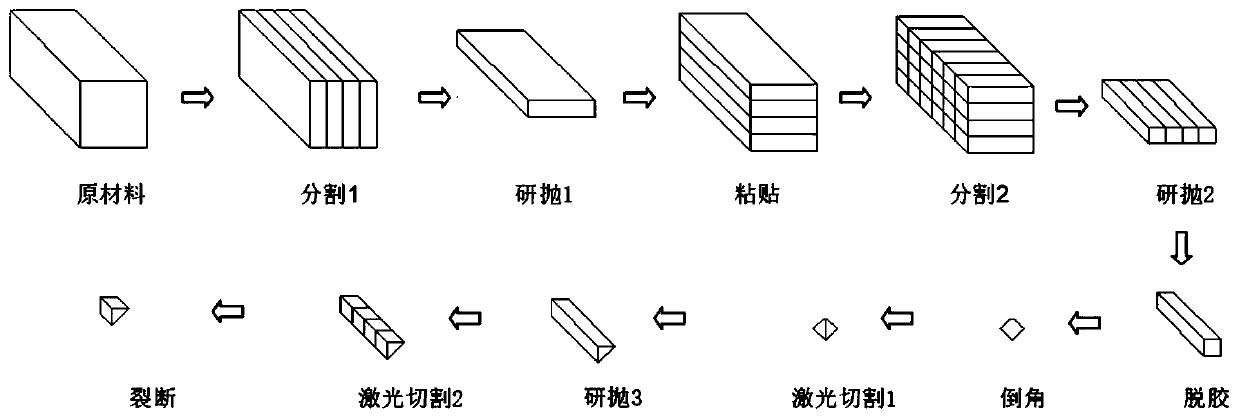

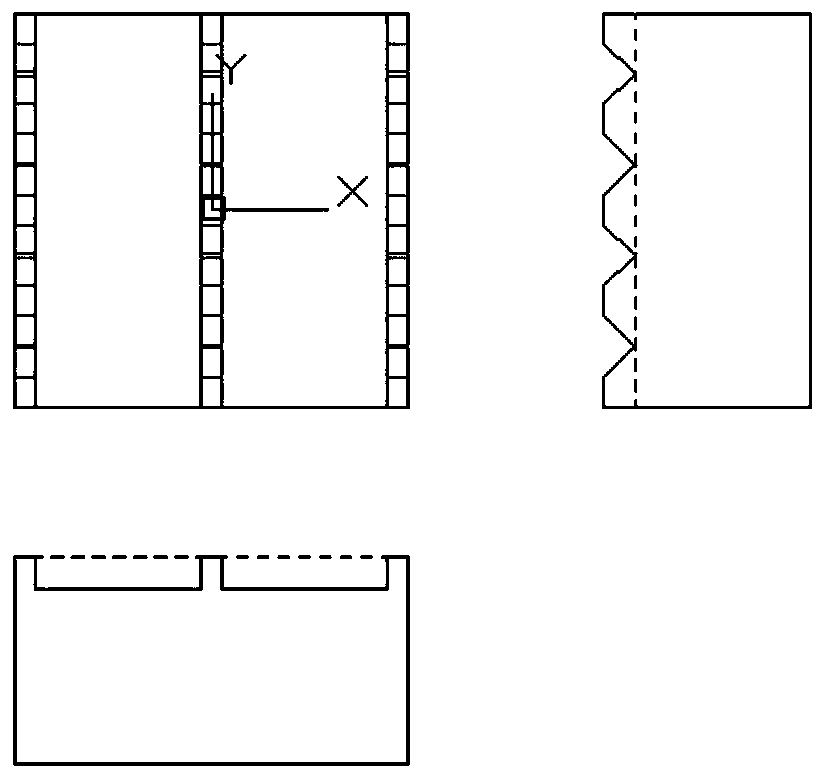

[0026] A kind of triangular prism processing technology, refer to figure 1 shown, including the following specific steps:

[0027] S1: Segmentation 1: Divide blocky raw materials into large sheet-like semi-finished products;

[0028] S2: Grinding and polishing 1: Grinding and polishing the upper and lower sides formed by dividing large-sheet semi-finished products;

[0029] S3: Bonding: the large sheet semi-finished product processed in step S2 is bonded together by water-soluble glue to obtain a large block semi-finished product;

[0030] S4: Divide 2: Divide the bulky semi-finished product in step S3 again to obtain a bonded small semi-finished product;

[0031] S5: Grinding and polishing 2: Grinding and polishing the upper and lower sides formed by cutting the small block semi-finished product in step S4, to obtain a straight quadrangular prism wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com