Silver selenide-cobalt diselenide composite material with Turing structure as well as preparation method and application of silver selenide-cobalt diselenide composite material

A technology of cobalt diselenide and composite materials, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor understanding of catalysts, and achieve good electrocatalytic moisture analysis and oxygen performance. Effect of high Faraday efficiency and low energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of silver selenide-cobalt diselenide composite material with Turing structure, comprising: mixing and reacting nanoribbon-shaped cobalt diselenide, silver salt, water and amine solvent to obtain Silver selenide-cobalt diselenide composite material with spirit structure.

[0035] Wherein, the present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0036] The nanoribbon-shaped cobalt diselenide is preferably prepared according to the following method: cobalt salt, sodium selenite, water and amine solvent are mixed, heated and reacted to obtain nanoribbon-shaped cobalt diselenide; the cobalt salt is preferably soluble Inorganic cobalt salt, more preferably one or more of cobalt sulfate, cobalt acetate and cobalt nitrate, more preferably cobalt acetate; the molar ratio of the cobalt salt and sodium selenite is preferably 1: (0.8~1.2) , more preferably 1:...

Embodiment 1

[0047] Dissolve 20mg of nanoribbon-shaped cobalt diselenide and 20mg of silver nitrate in a mixed solution of 10mL diethylenetriamine and 5mL deionized water, and obtain a uniform solution after ultrasonication at 300W for 5min, then put it into a 50mL beaker at room temperature 200rpm After stirring for four hours, the obtained product was centrifuged, washed three times with deionized water and three times with ethanol, and dried in vacuum to obtain a silver selenide-cobalt diselenide composite material with a Turing structure.

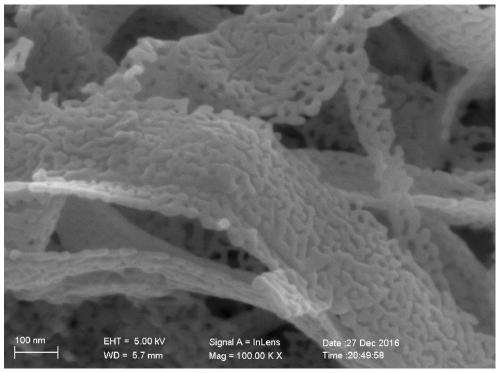

[0048] Utilize scanning electron microscope to analyze the Turing structure silver selenide-cobalt diselenide obtained in embodiment 1, obtain its scanning electron microscope picture, as figure 1 shown.

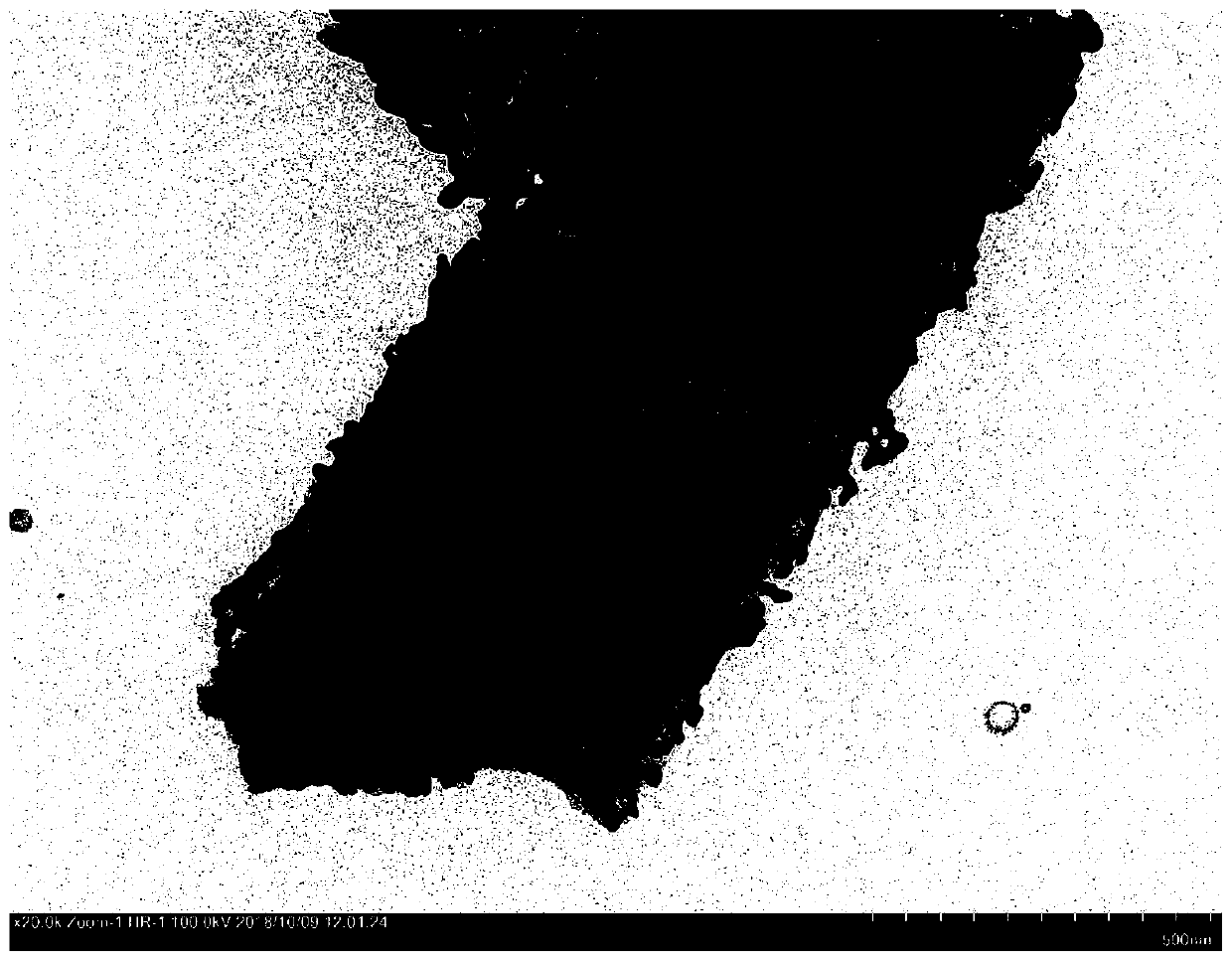

[0049] Utilize transmission electron microscope to analyze the silver selenide-cobalt diselenide composite material with Turing structure obtained in embodiment 1, obtain its transmission electron microscope photograph, as figure 2 shown.

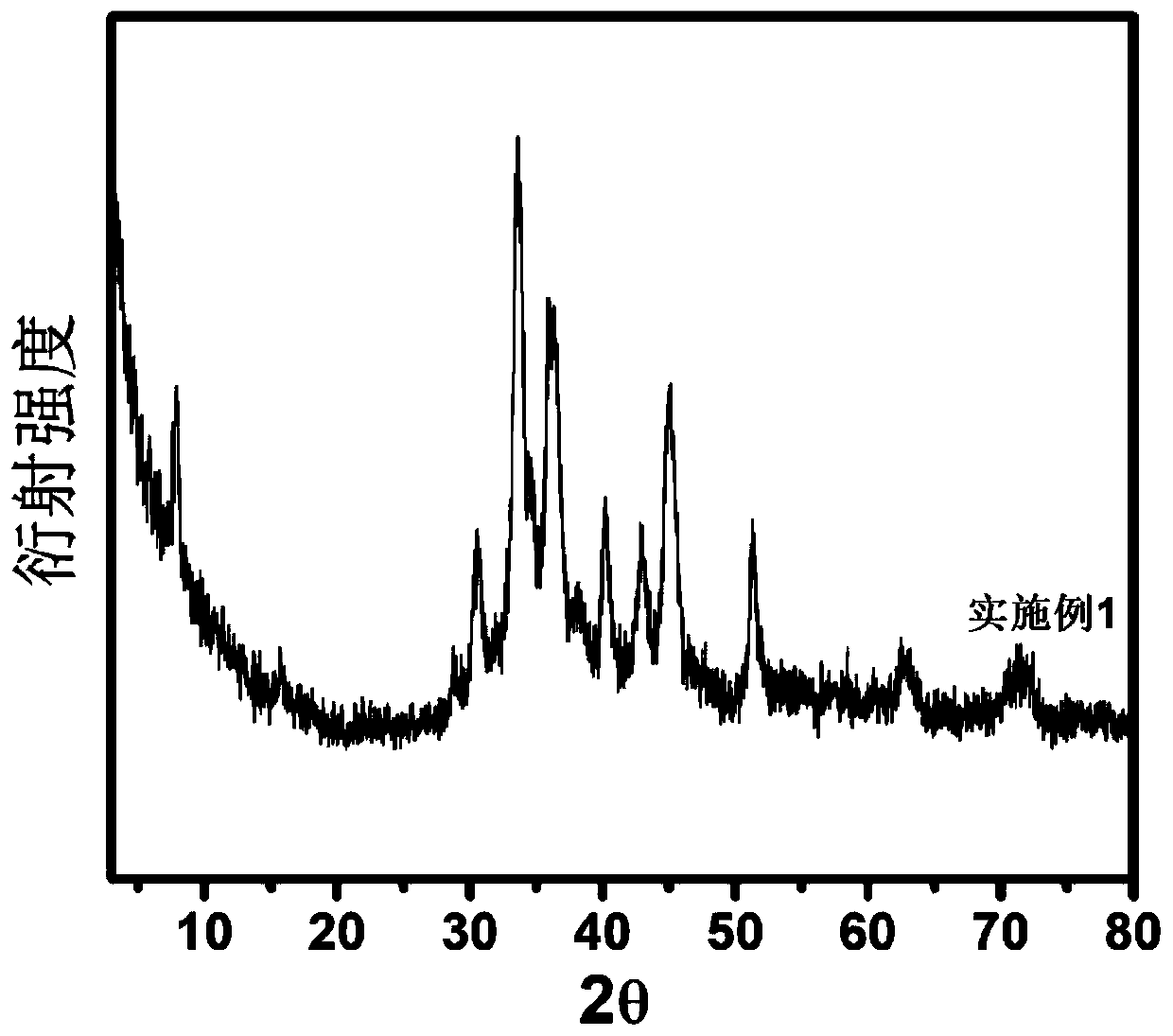

[00...

Embodiment 2

[0055] Dissolve 20mg of nanoribbon-shaped cobalt diselenide and 5mg of silver nitrate in a mixed solution of 10mL diethylenetriamine and 5mL deionized water, and obtain a uniform solution after ultrasonication at 300W for 5min, then put it into a 50mL beaker at room temperature 200rpm After stirring for four hours, the obtained product was centrifuged, washed three times with deionized water and three times with ethanol, and dried in vacuum to obtain a silver selenide-cobalt diselenide composite material with a Turing structure.

[0056] Utilize scanning electron microscope to analyze the silver selenide-cobalt diselenide composite material with Turing structure obtained in embodiment 2, obtain its scanning electron microscope picture, as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com