Permanent magnet motor

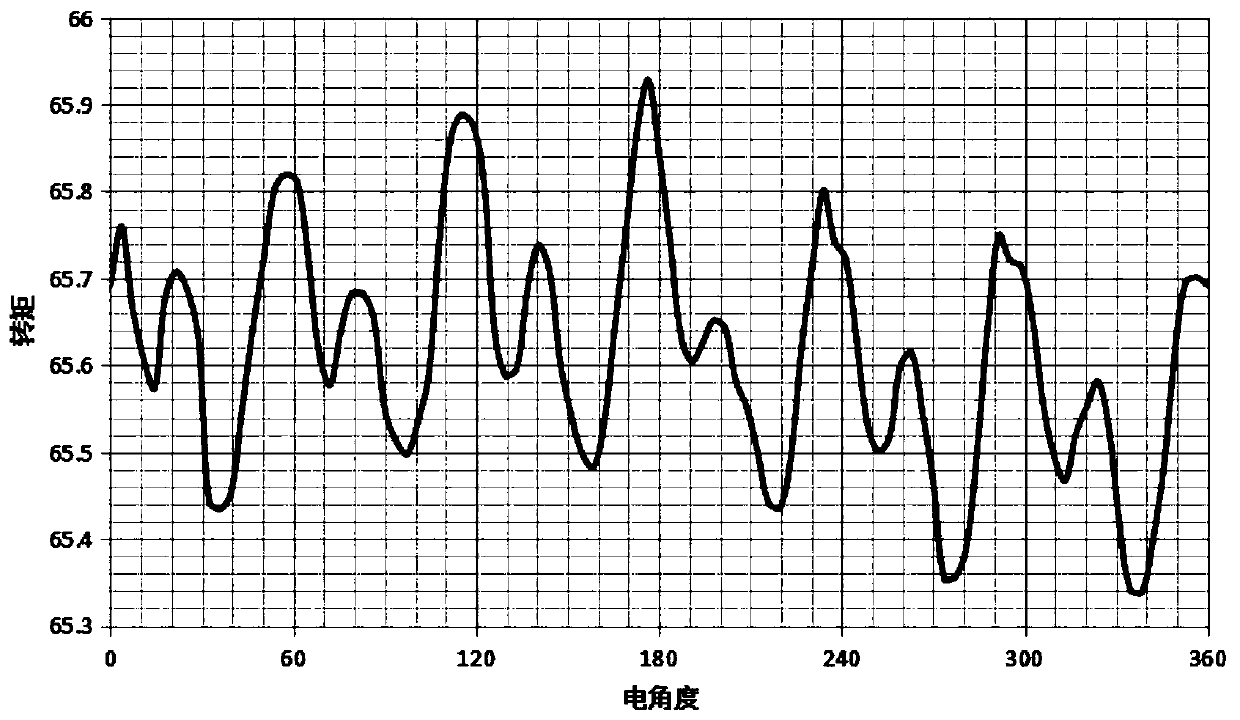

A technology of permanent magnet motor and electrical angle, applied in the direction of magnetic circuit, electrical components, electromechanical devices, etc., can solve the problems of motor bearings reducing motor life and reliability, and achieve the goal of improving reliability and service life and reducing torque fluctuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

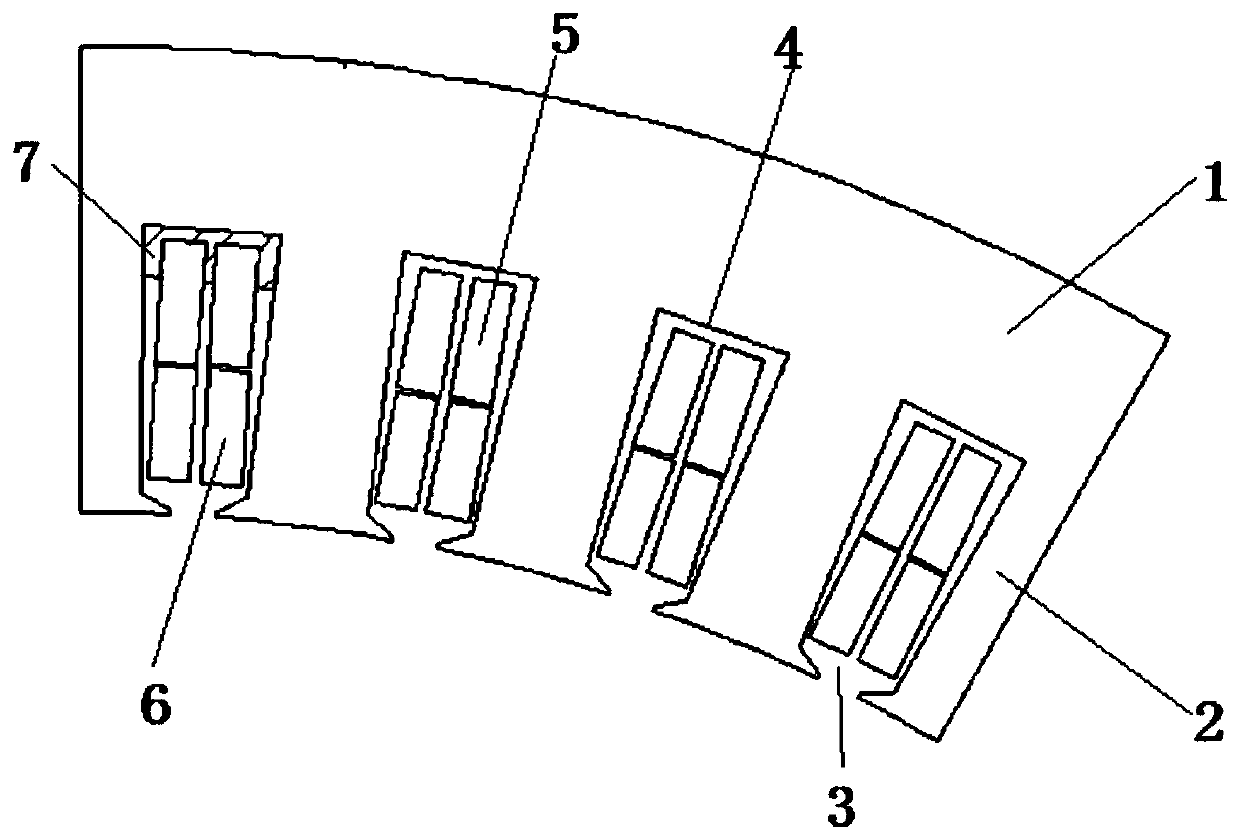

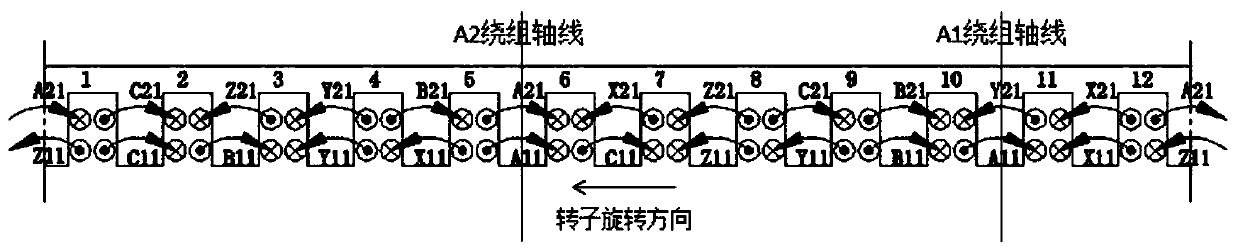

[0015] The permanent magnet motor of the present embodiment comprises a stator and a rotor; the number of rotor poles is 10Y, and Y is a constant; as figure 1 As shown, the stator includes a connected stator yoke 1 and a plurality of stator teeth 2, and the stator teeth 2 are parallel teeth, and trapezoidal stator slots 3 are formed between adjacent stator teeth 2, and the number of stator slots 3 is 12Y, and the stator teeth 2. The coils are wound on top to form two sets of windings, and each stator slot 3 contains the two sets of windings. The stator and the windings are vacuum potted with epoxy resin as a whole. The bottom of the stator slot 4 and the side walls of the slot near the bottom of the stator slot 4 Before the processing goes off-line, the heat-conducting glue 7 is pre-coated, and at least one set of temperature-measuring elements is set in the stator slot 3 to control the current difference in each set of windings according to the temperature value of the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com