switchgear or controlgear

A control device and switchgear technology, which is applied in the settings of switchgear, switchgear, and switchgear components, etc., can solve problems such as automation system complexity and weight handling constraints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

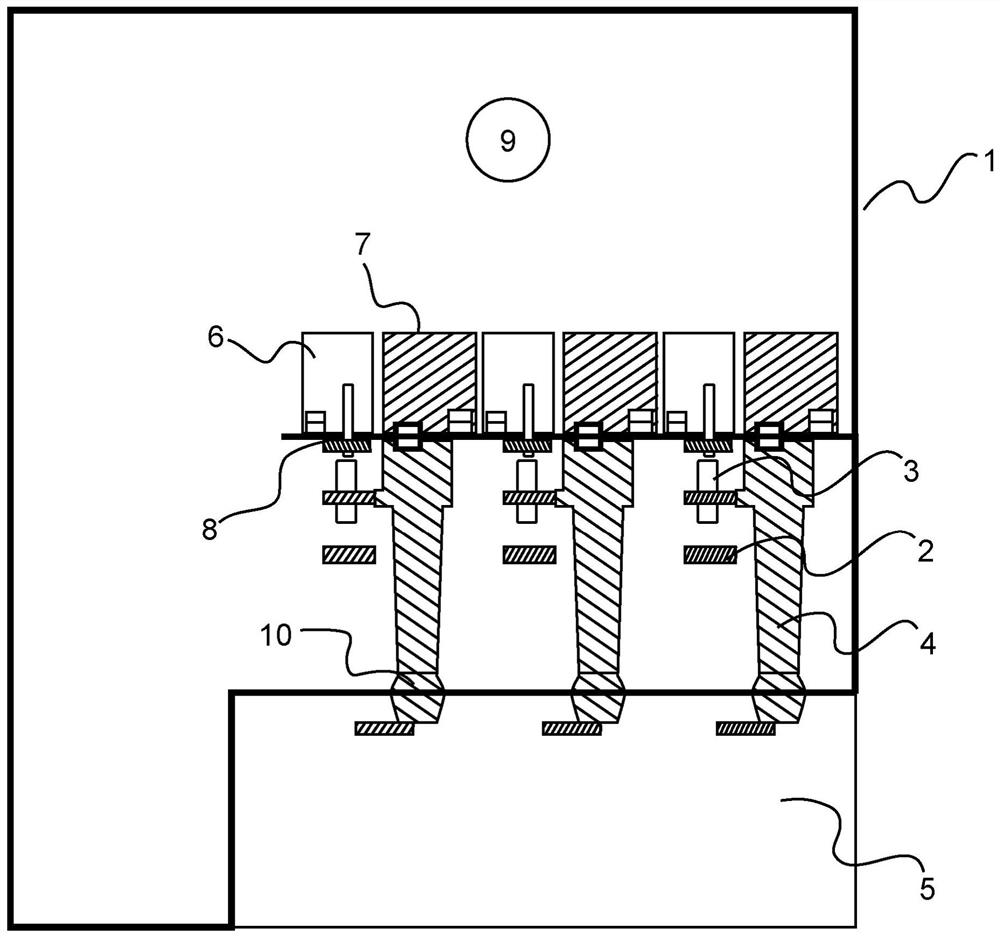

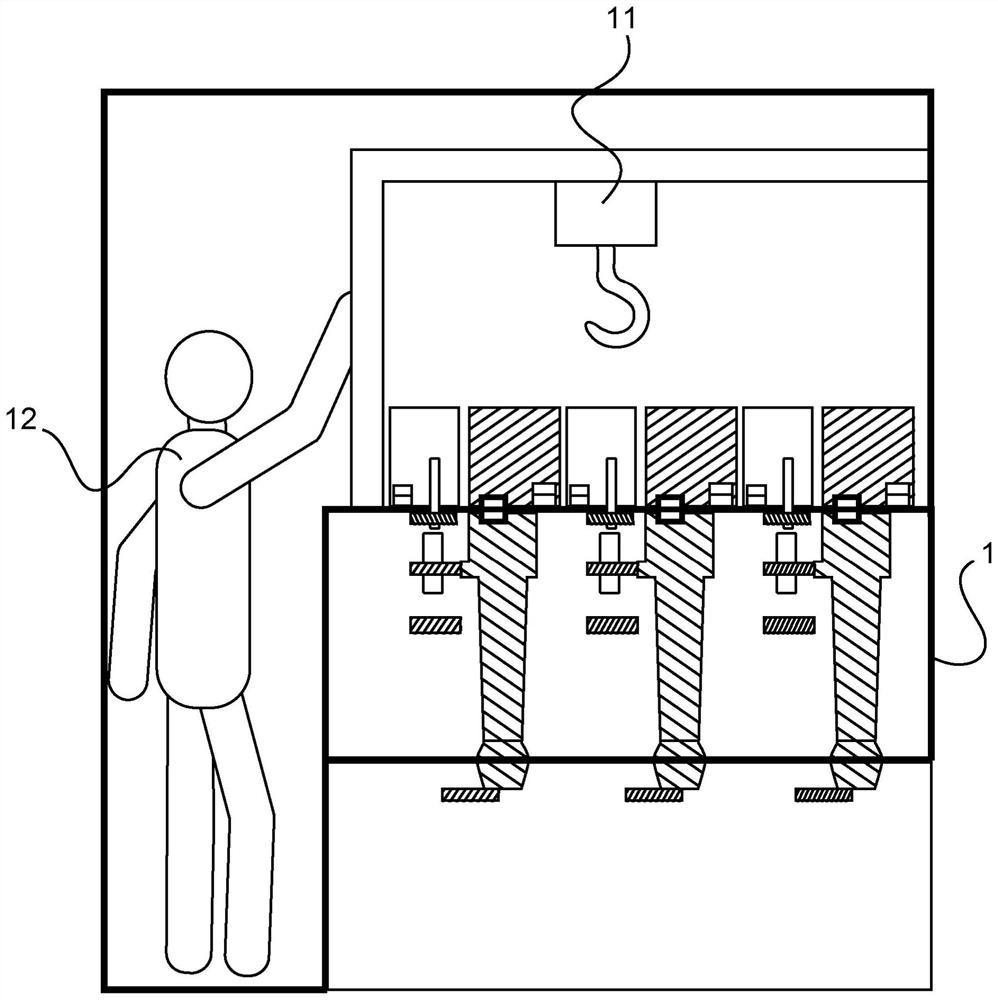

[0055] Figure 1 to Figure 2 An example of a switchgear or control device for operation in a low voltage substation, a medium voltage substation or a high voltage substation is shown.

[0056] One example relates to a switchgear or controlgear, at least one first compartment 1, 5, 9, a plurality of removable modules 6, 7, a plurality of main switchgear or controlgear assemblies, and a plurality of auxiliary switchgear or Control unit components. The plurality of main switchgear or control gear assemblies comprises at least one main busbar system 2, at least one three-position linear or rotary movement disconnector 3, at least one circuit breaker pole 4, and at least one cable connection. The plurality of auxiliary switchgear or control gear assemblies includes at least one disconnect switch driver and at least one circuit breaker driver. A plurality of removable modules are configured to be mounted horizontally within the at least one first compartment at a plurality of hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com