Three-dimensional scintillator optical fiber array X-ray detector and preparation method thereof

A fiber array and scintillator technology, applied in the field of X-ray imaging, can solve problems such as optical signal crosstalk, achieve high sensitivity, meet the needs of use, and achieve high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

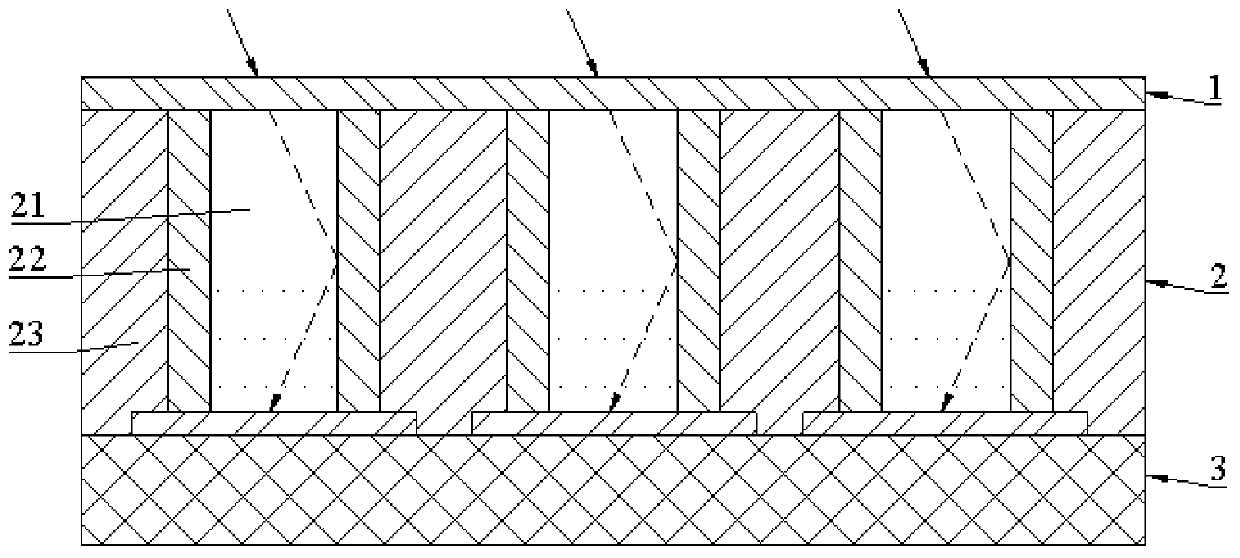

[0039] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0040] A method for preparing a three-dimensional scintillator fiber optic array X-ray detector, comprising the steps of:

[0041] 1. After mixing methyl methacrylate, initiator and chain transfer agent, carry out prepolymerization reaction to obtain prepolymer.

[0042] In this embodiment, methyl methacrylate undergoes an in-situ polymerization reaction, and the reaction is carried out under the protection of an inert gas, and the inert gas is one of nitrogen, argon and helium. The mass ratio of the methyl methacrylate, the initiator and the chain transfer agent is 100:(0.05-0.2):(0.05-0.1). The initiator may be azobisisobutyronitrile, and the chain transfer agent may be 1-decanethiol. Weigh the methyl methacrylate, initiator and chain transfer agent and place them in a three-necked bottle, mix well, stir with a magnetic stirrer, and gradually raise the temperature to 80°C by means of an oil bath...

Embodiment 2

[0058] Embodiment 2 of the present invention is: a method for preparing a three-dimensional scintillator fiber optic array X-ray detector, which differs from Embodiment 1 in that:

[0059] The mass ratio of methyl methacrylate, initiator and chain transfer agent described in step 1 is 100:0.1:0.08; The mass ratio of release powder and methyl methacrylate in step 2 is 0.18:100, and the flashing The mass ratio of the scintillator to methyl methacrylate is 5:100; the temperature control treatment is specifically: the vacuum-treated scintillator prepolymer is incubated at 70°C for 12h, 60°C for 12h, and 85°C. Insulate at 100°C for 24 hours, at 100°C for 24 hours, and at 115°C for 24 hours.

Embodiment 3

[0061] Embodiment 3 of the present invention is: a method for preparing a three-dimensional scintillator fiber optic array X-ray detector, which is different from Embodiment 1 in that:

[0062] The mass ratio of methyl methacrylate, initiator and chain transfer agent described in step 1 is 100:0.05:0.1; The mass ratio of release powder and methyl methacrylate in step 2 is 0.15:100, and the flashing The mass ratio of scintillator to methyl methacrylate is 0.2:100; the temperature control treatment is specifically: the vacuum-treated scintillator prepolymer is kept at 68°C for 14h, 58°C for 14h, and 87°C. Incubate at 102°C for 22 hours, at 102°C for 22 hours, and at 113°C for 26 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com