On-line monitoring device for diameter and roundness of expanded pipeline

A technology of pipe diameter and monitoring device, which is applied in measuring device, mechanical measuring device, mechanical diameter measuring and other directions, can solve the problems of low measurement efficiency, high labor intensity of workers, low measurement accuracy, etc., and achieves reduced labor intensity and fast measurement speed. , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

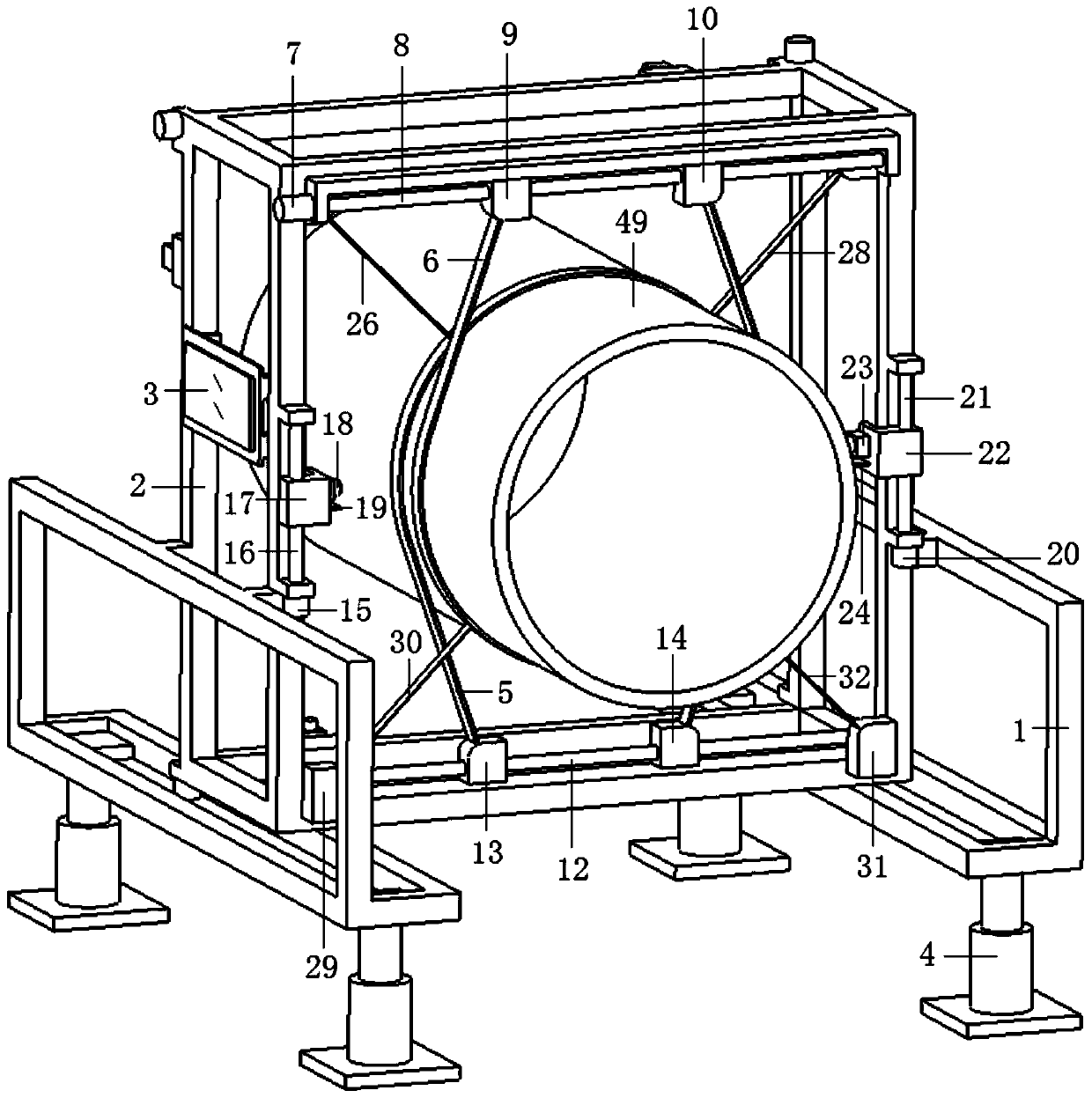

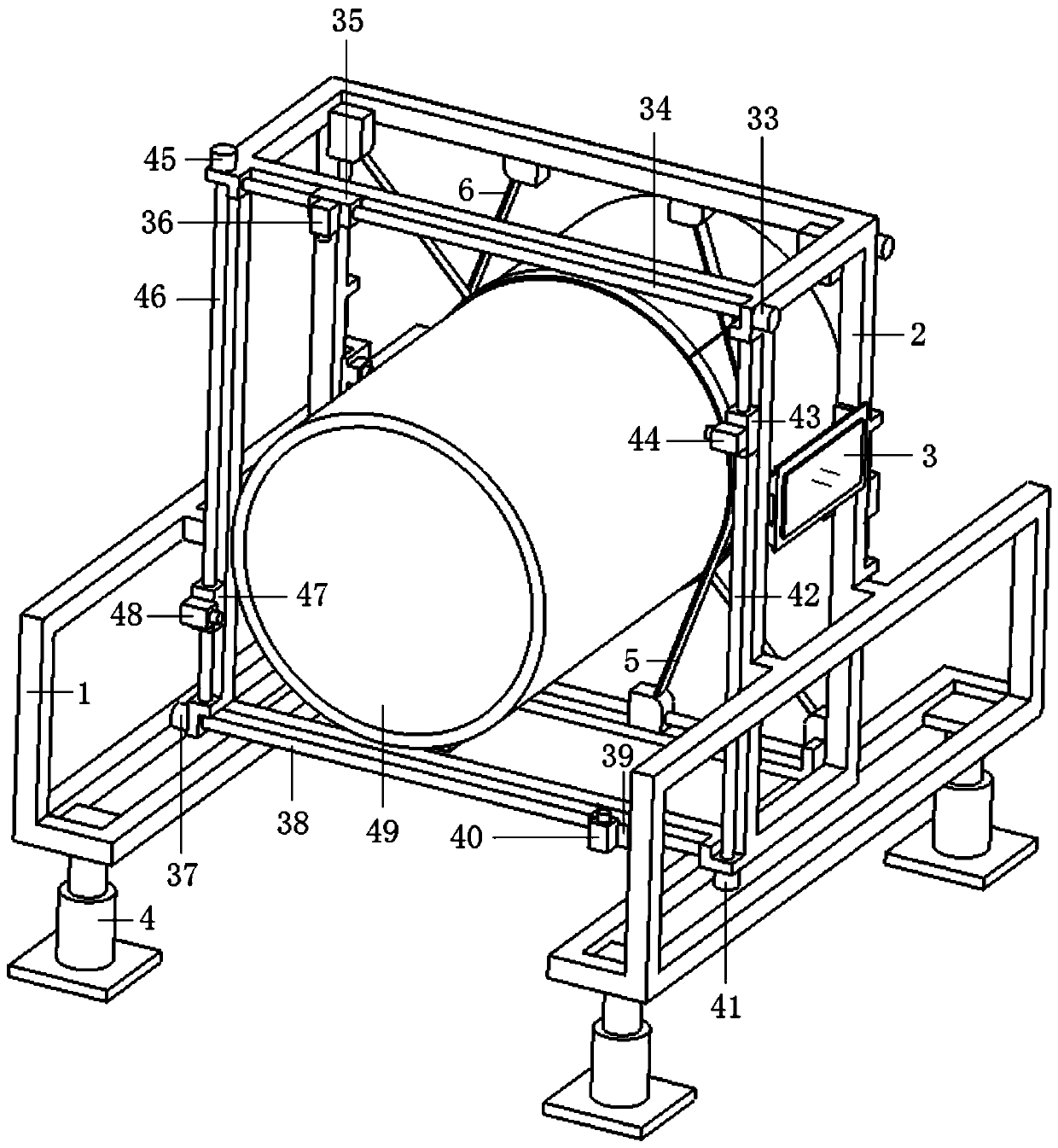

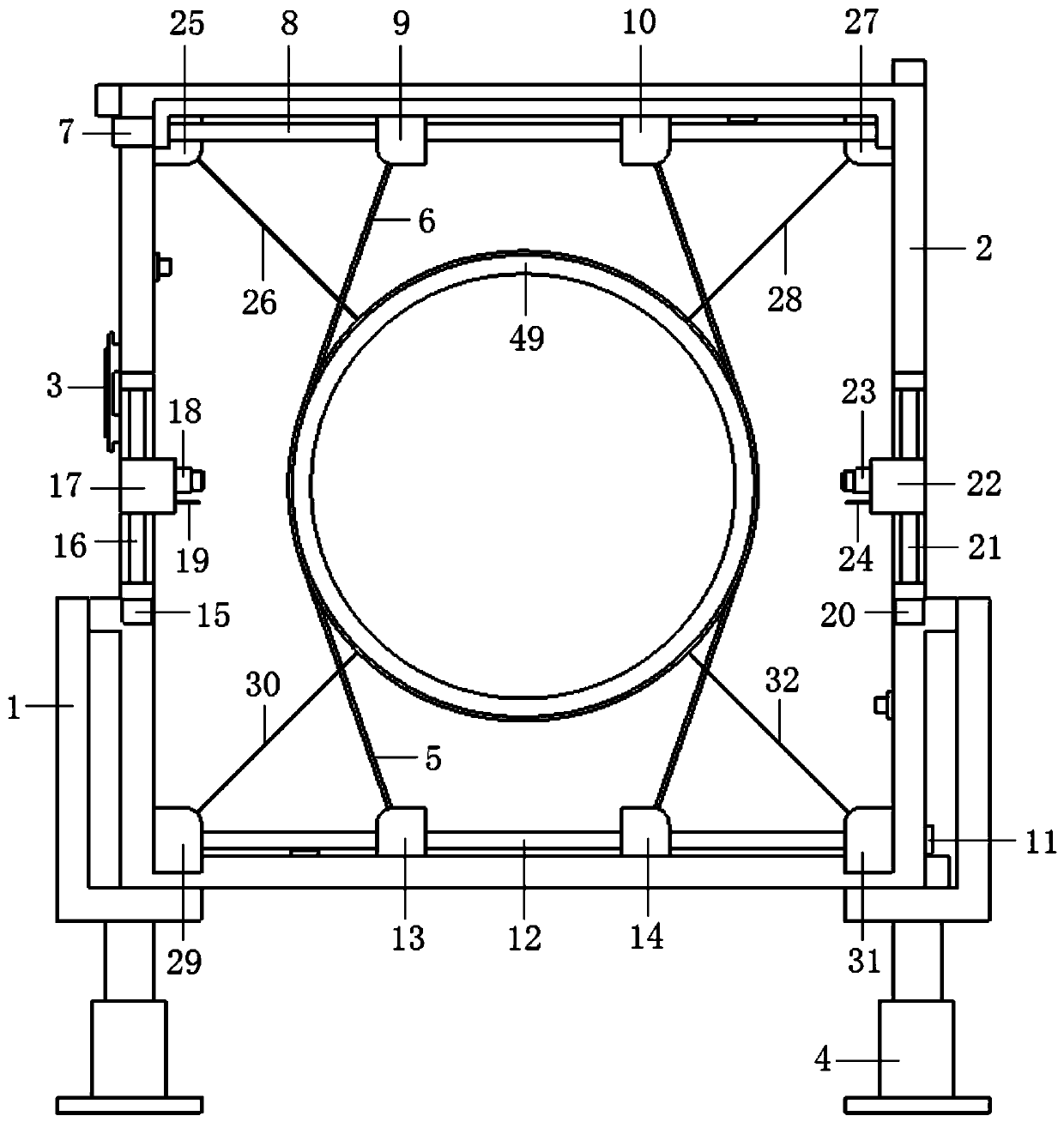

[0024] Such as Figure 1~3 As shown, an on-line monitoring device for the diameter and roundness of expanded pipes, including a base 1, a pedestal 2, a computer 3, a pipe diameter measurement component and a pipeline roundness measurement component; the bottom of the base 1 is evenly arranged with a number of lifting columns 4. The height of the base 1 is adjusted through the expansion and contraction of the lifting column 4; the base frame 2 adopts a rectangular frame structure, and the base frame 2 is vertically fixed on the base 1; the computer 3, the pipeline diameter measurement component and the pipeline The roundness measuring components are all installed on the base frame 2 .

[0025] The computer 3 is fixedly mounted on the base frame 2 through an external bracket, and the computer 3 is provided with a touch panel, and a man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com