Connecting structure between locking anchor pipe and steel rack and mounting method thereof

A technology for locking foot anchor pipes and connecting structures, which is applied in the installation of anchor rods, shaft equipment, earthwork drilling and mining, etc. It can solve problems such as solder joints falling off and connection failures, and achieves convenient welding and fixing, increased pull-out resistance, and improved resistance. The effect of bending ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

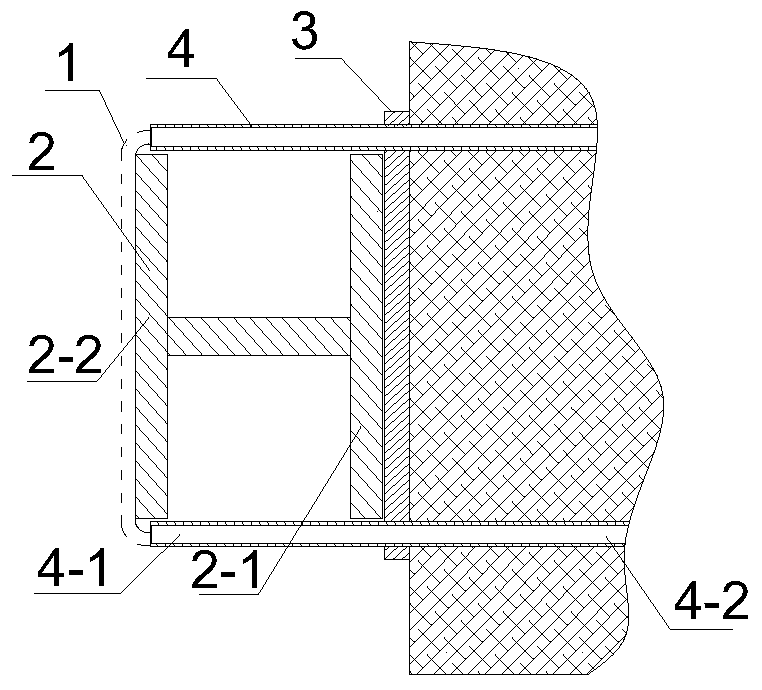

[0041] Such as Figure 1-4 As shown, a connection structure between the locking foot anchor pipe and the steel frame is used for the connection between the locking foot anchor pipe 4 and the steel frame 2, and is characterized in that it includes:

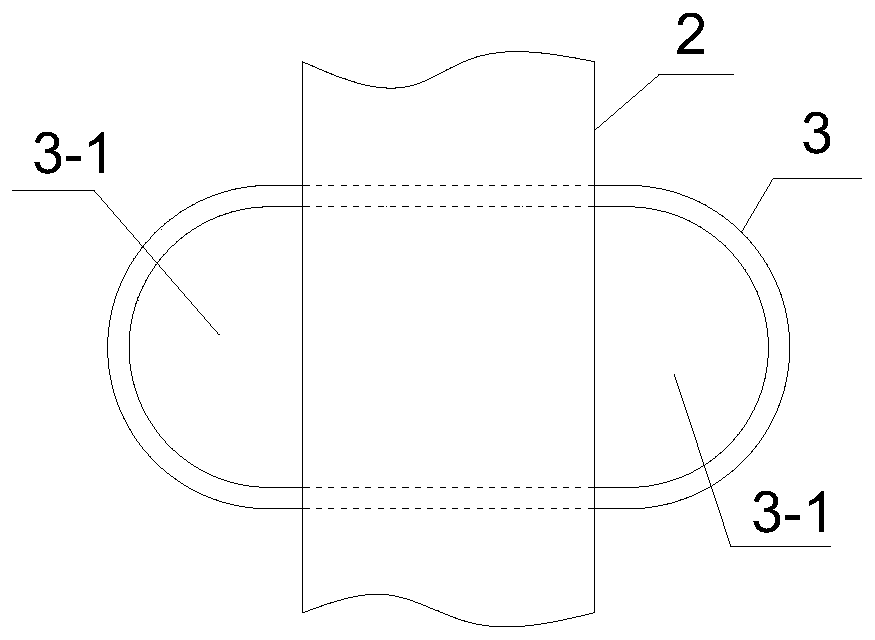

[0042] The ring-shaped steel bar 3 is fixed on the end surface of the steel frame 2 close to the surrounding rock, and a perforation 3-1 is respectively exposed on both sides of the steel frame 2, and two locking foot anchor pipes 4 pass through the two perforations 3-1 respectively;

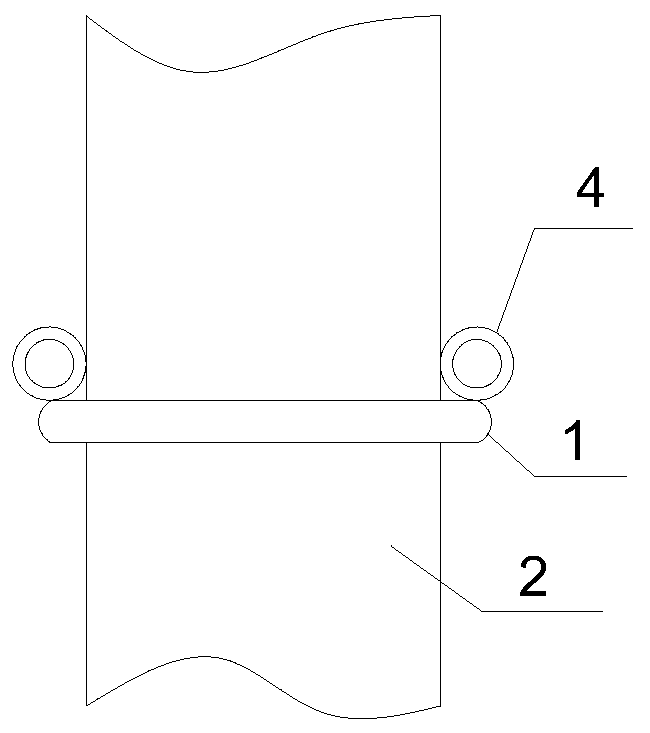

[0043] The connecting steel bar 1 is U-shaped, and the two ends of the connecting steel bar 1 are respectively connected to the outer ends 4-1 of the two locking foot anchor pipes 4 .

[0044] The above-mentioned annular steel bar 3 is welded and fixed to the steel frame 2; In this embodiment, the welding seam between the annular steel bar 3 and the steel frame 2 adopts the surfacing welding method, and the welding seam between the connecting steel ...

Embodiment 2

[0049] In this embodiment, on the basis of Embodiment 1, the device is fixedly connected to the end face of the steel frame 2 away from the surrounding rock, and the connecting steel bar 1 and the steel frame 2 are welded and fixed. The steel frame 2 is an I-beam, and its second wing plate 2-2 away from the surrounding rock is fixedly connected with the connecting steel bar 1, and its welding seam also adopts a surfacing welding method. After the connecting steel bar 1 and the steel frame 2 are welded and fixed, the connecting steel bar 1, the steel frame 2 and the locking foot anchor pipe 4 are combined into a whole, which can cooperate to resist deformation force and pulling force.

Embodiment 3

[0051] Such as Figure 5-7 As shown, in this embodiment, on the basis of Embodiment 2, a limit mechanism 5 is provided at both ends of the annular steel bar 3 of the device, which is used to limit the position of the locking foot anchor tube 4 .

[0052] The limiting mechanism 5 includes a limiting block 5-1, and the hole wall of the perforation 3-1 is provided with a limiting groove 3-2 in shape with the limiting block 5-1, and the limiting block 5-1 is Located in the limit groove 3-2, the cross section of the limit block 5-1 is a right triangle, its right angle face is facing the surrounding rock, and the other right angle face is facing the locking foot anchor pipe 4, and the slope faces the circular steel bar 3. The limiting block 5-1 is provided with a clamping block 5-2 at an acute angle facing away from the surrounding rock, and the clamping block 5-2 prevents the limiting block 5-1 from moving toward the surrounding rock.

[0053] The limiting block 5-1 is in the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com