Indoor decoration device

A technology for interior decoration and painting, applied in mixers with rotary stirring devices, transportation and packaging, mixers, etc., can solve the problems of high time cost, material dripping, uneven paint, etc., and achieve balanced feeding methods. Avoid hidden dangers, the effect of large displacement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

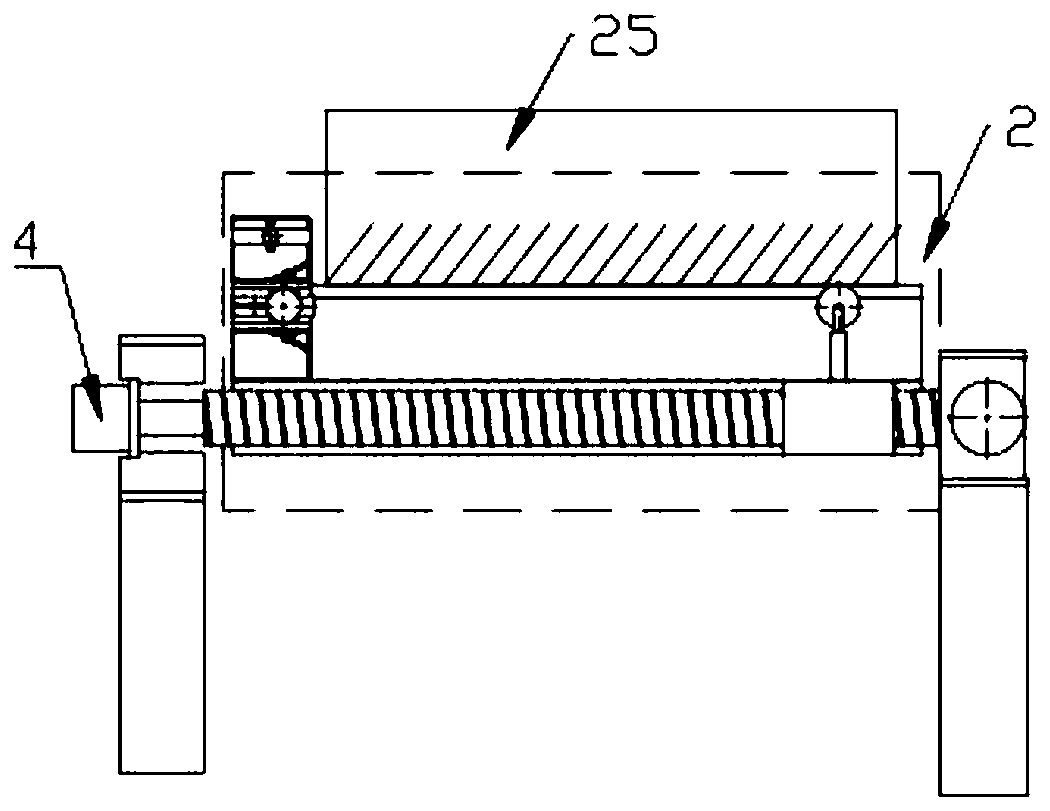

[0043] An interior decoration device, see Figure 1 to Figure 10 , including the fixing block 3 of the painting mechanism 2 installed on the screw type lifting frame 1, the painting mechanism 2 is installed on the fixing block 3, the displacement line is parallel to the horizontal plane, and one end of the screw is installed with a transverse motor 4. There is a transverse sliding block on the lead screw, and the transverse sliding block is connected to the coating mechanism. A pressure regulating device is provided between the coating roller 24 of the coating mechanism 2 and the transverse sliding block to make the coating mechanism 2 close to the treated On the wall, an automatic feeding mechanism is installed on the side of the fixing block 3 away from the horizontal motor 4;

[0044] The lead screw lift frame 1 includes a slider 5, a vertical slide rail that limits the freedom of the slider 5, and a vertical lead screw 6 that drives the slider 5 to move up and down. A ver...

Embodiment 2

[0053] The principle of this embodiment is the same as that of Embodiment 1, and the specific difference is: Figure 7 , the width of the automatic feeding mechanism is reduced to prevent it from interfering with the painting roller 24, and it does not affect the painting of the wall. Compared with the design in Example 1, where a part of the equipment is located at the door frame, the use space of this design is more. big.

Embodiment 3

[0055] The principle of this embodiment is the same as that of Embodiment 1, and the specific difference is: Figure 9 , the top support plate is provided with a rocker 17, and the power source of the friction roller is replaced by manual, which reduces the cost of equipment coordination. During the process of outward extrusion, proper bidirectional rotation can promote the elastic baffle 10 to be in the best position. Location.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com