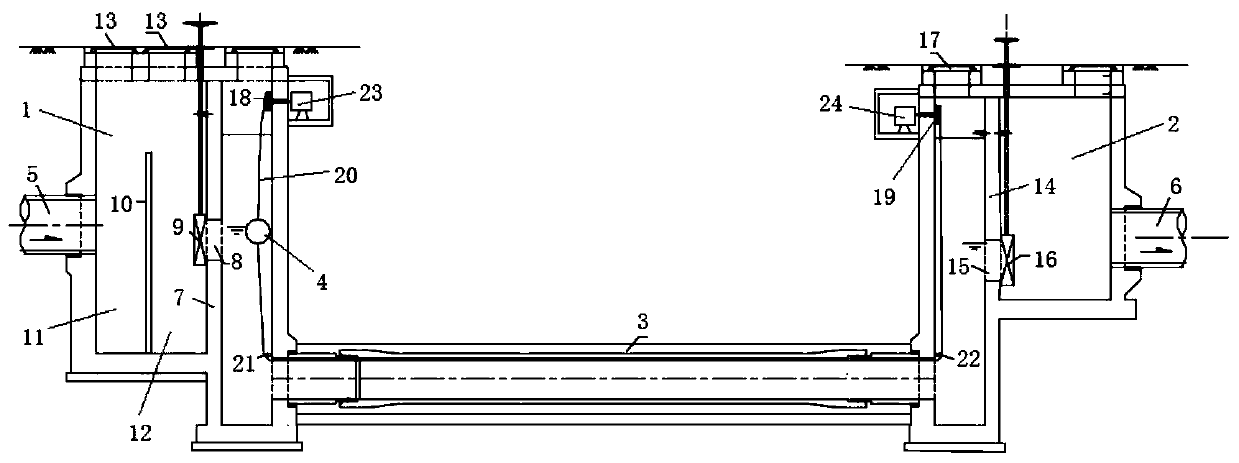

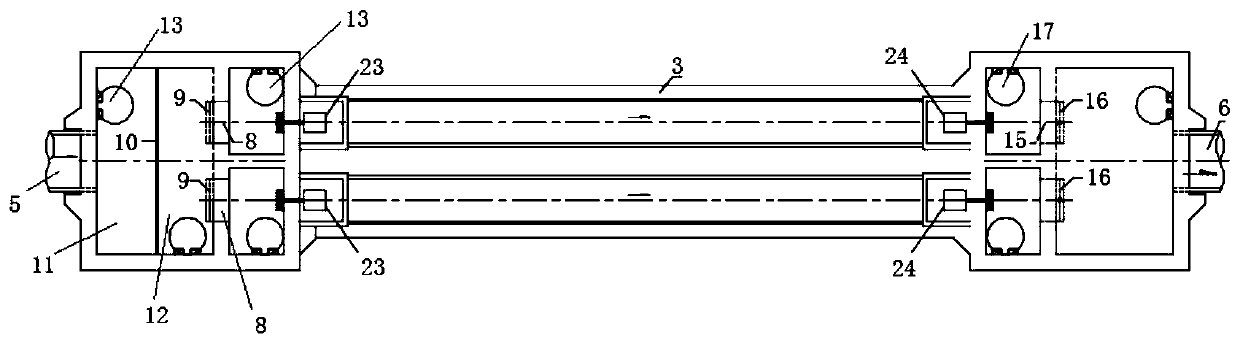

Inverted siphon system and desilting method

A technology of inverted rainbow and inverted rainbow well, which is applied in the direction of waterway system, cleaning sewer pipes, drainage structures, etc., and can solve the problems of increasing construction period, construction complexity and construction cost, increasing the buried depth of downstream inverted rainbow well, and dredging treatment Difficulties and other problems, to achieve significant economic benefits, increase the construction period, the effect of convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] This embodiment discloses the desilting method of the pouring system described in Example 1: the sewage in the upstream sewage pipe enters the upstream pouring well, and the larger impurities in the sewage are intercepted under the action of the grid plate and remain in the desilting The sewage in the slag space and the sedimentation space enters the inverted siphon after the impurities are precipitated. At this time, the sewage in the inverted siphon has less impurities. The sewage in the inverted siphon enters the downstream inverted siphon well and then flows out through the downstream sewage pipe. After a period of use Finally, there will still be impurities remaining in the inverted siphon. At this time, the staff opens the first inspection well and the second inspection well corresponding to the second chamber and the third chamber, and uses the control system to control the first motor and the second motor to drive The rotation of the first turntable and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com