Mold for machining producing of fuse insulator

A technology for insulators and fuses, which is applied in the field of molds for processing and producing fuse insulators, can solve the problems that insulator molds cannot be shared, reduce the market competitiveness of insulators, increase the production cost of insulators, etc., achieve good buffering effect, improve efficiency, The effect of guaranteeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will make a clear and complete description of the mold for processing and producing fuse insulators of the present invention in conjunction with the accompanying drawings.

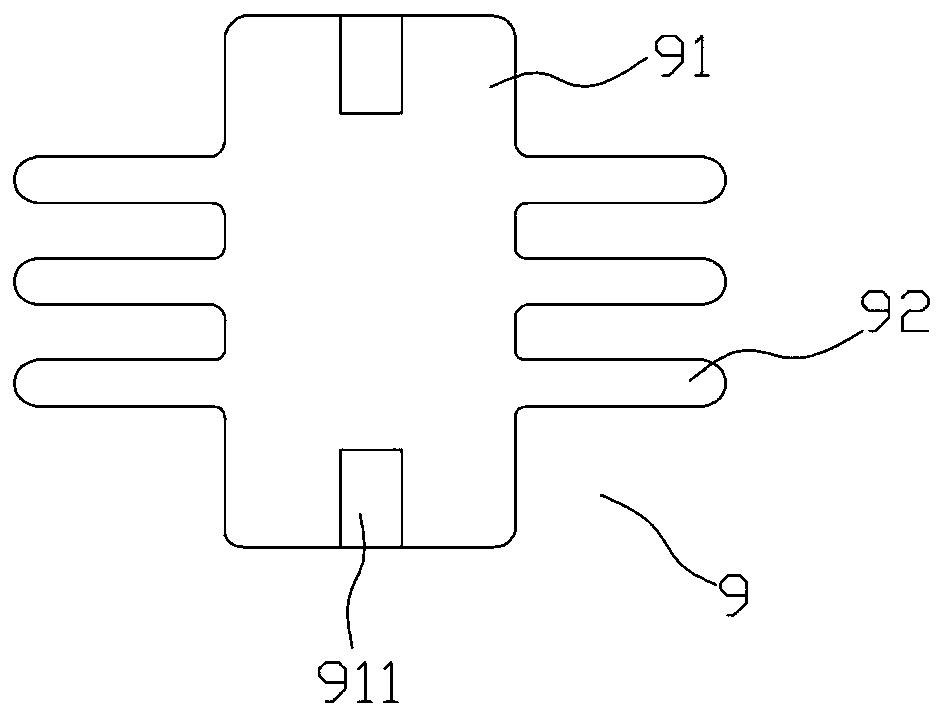

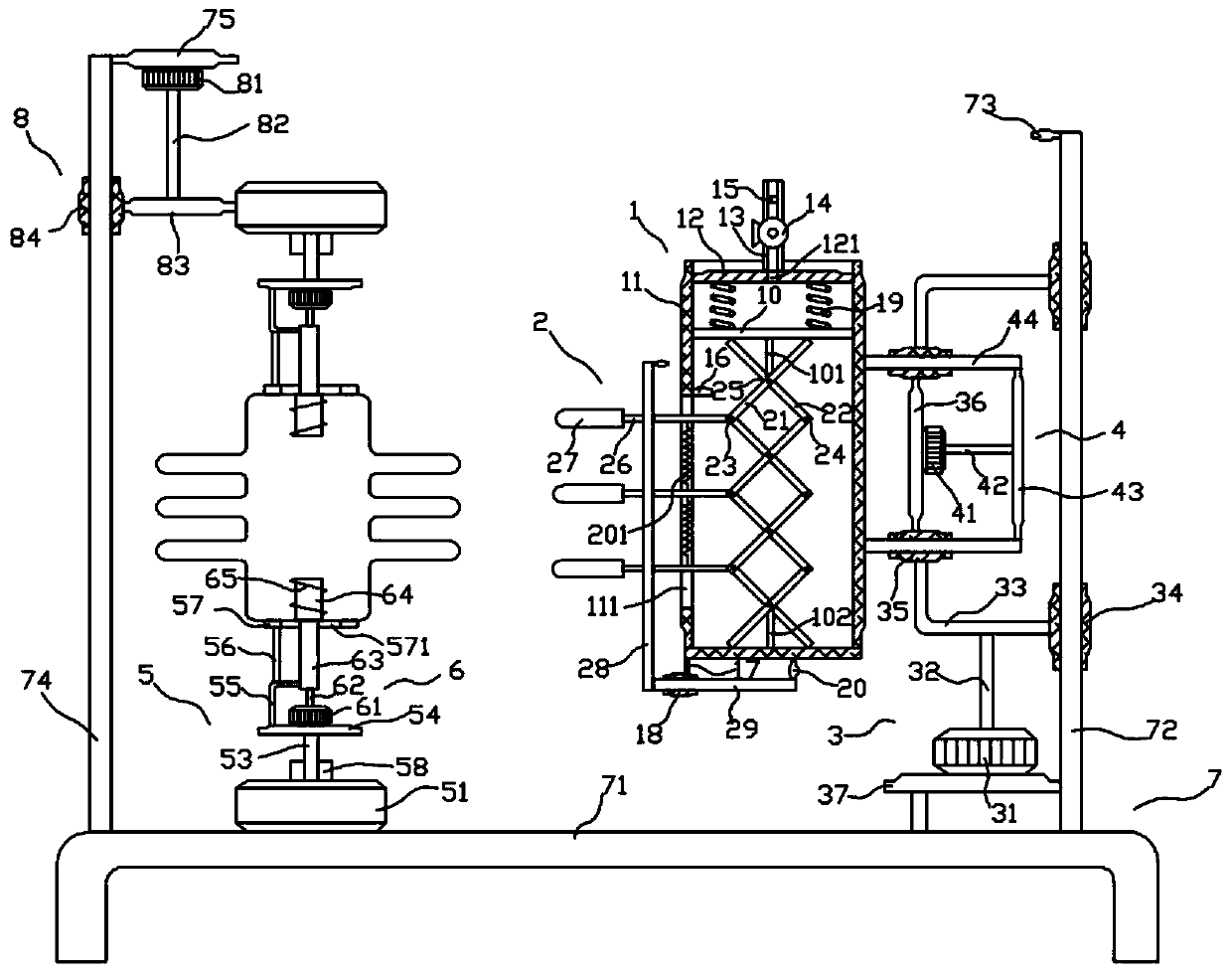

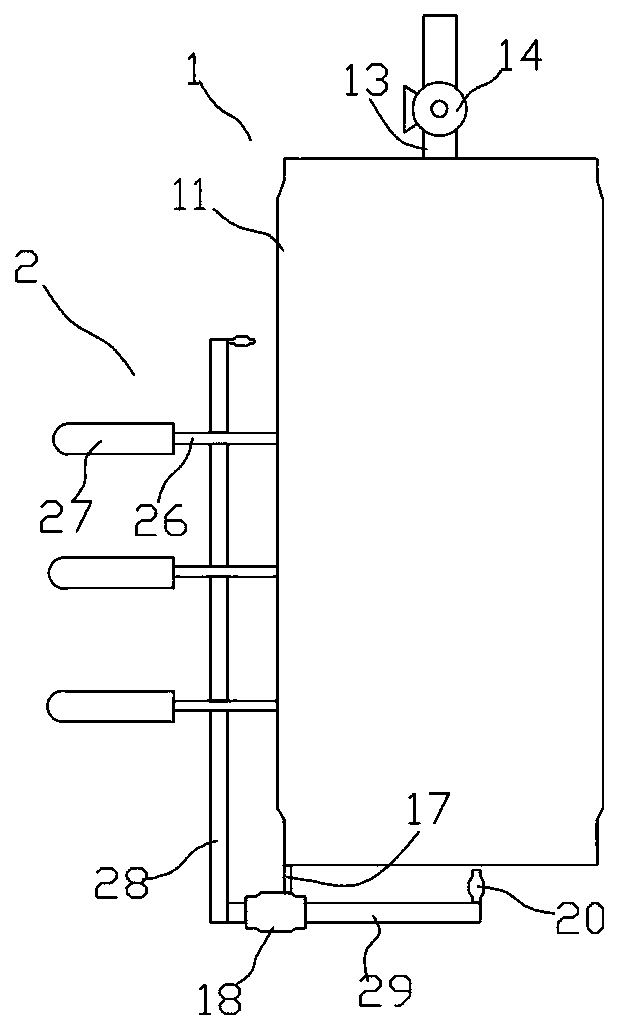

[0018] Such as Figure 2 to Figure 9 As shown, the mold for fuse insulator processing and production of the present invention includes a shell structure 1, an equidistant adjustment structure 2 arranged on the housing structure 1, and an equidistant adjustment structure 2 inserted on the equidistant adjustment structure 2. Several scrapers 27, a drive structure 4 that drives the horizontal movement of the equidistant adjustment structure 2, a push structure 3 that drives the vertical movement of the housing structure 1, a rotating structure 5 arranged on one side of the equidistant adjustment structure 2, A helical structure 6 arranged on the rotating structure 5 . The mold for fuse insulator processing and production also includes a support structure 7 and a height adjustment structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com