Elevator weighing device

A weighing device and elevator technology, applied in the field of vertical elevators, can solve the problems of inability to effectively adjust the uniform tension of the wire rope, inability to accurately detect the car load, affecting the detection accuracy of the weighing signal, etc., so as to save engineering and labor costs and reduce car costs. The cost and design difficulty of the cabin material, and the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

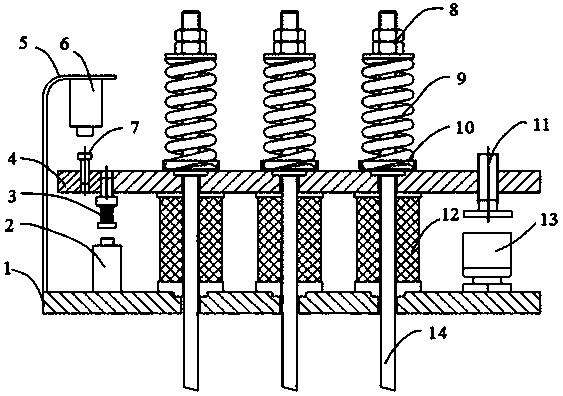

[0020] Such as figure 1 As shown, a weighing device for an elevator includes a fixed rope head plate 1 and an intermediate support plate 4 above the rope head plate 1, and several rubber tubes distributed side by side are arranged between the rope end plate 1 and the intermediate support plate 4 12. The upper end of the intermediate support plate 4 is provided with several rope end springs 9 corresponding to the rubber cylinder 12 , and the rope end springs 9 are placed on the round hole on the upper surface of the intermediate support plate 4 through the spring seat 10 . The rope end plate 1 is provided with an eddy current sensor 13, an overload detection switch 2, a loose rope detection switch bracket 5 and a loose rope detection switch 6, and an eddy current sensor magnetic resistance plate 11 which is inductively matched with the eddy current sensor 13 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com