Wiring harness threading pipeline welding machine and welding method

A welding machine and pipeline technology, applied in the field of wire harnesses, can solve the problems of difficult to find the pipeline positioning center, low pipeline positioning accuracy, complicated feeding action, etc., and achieve the effects of high welding efficiency, simple and reliable mechanism, and improved success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

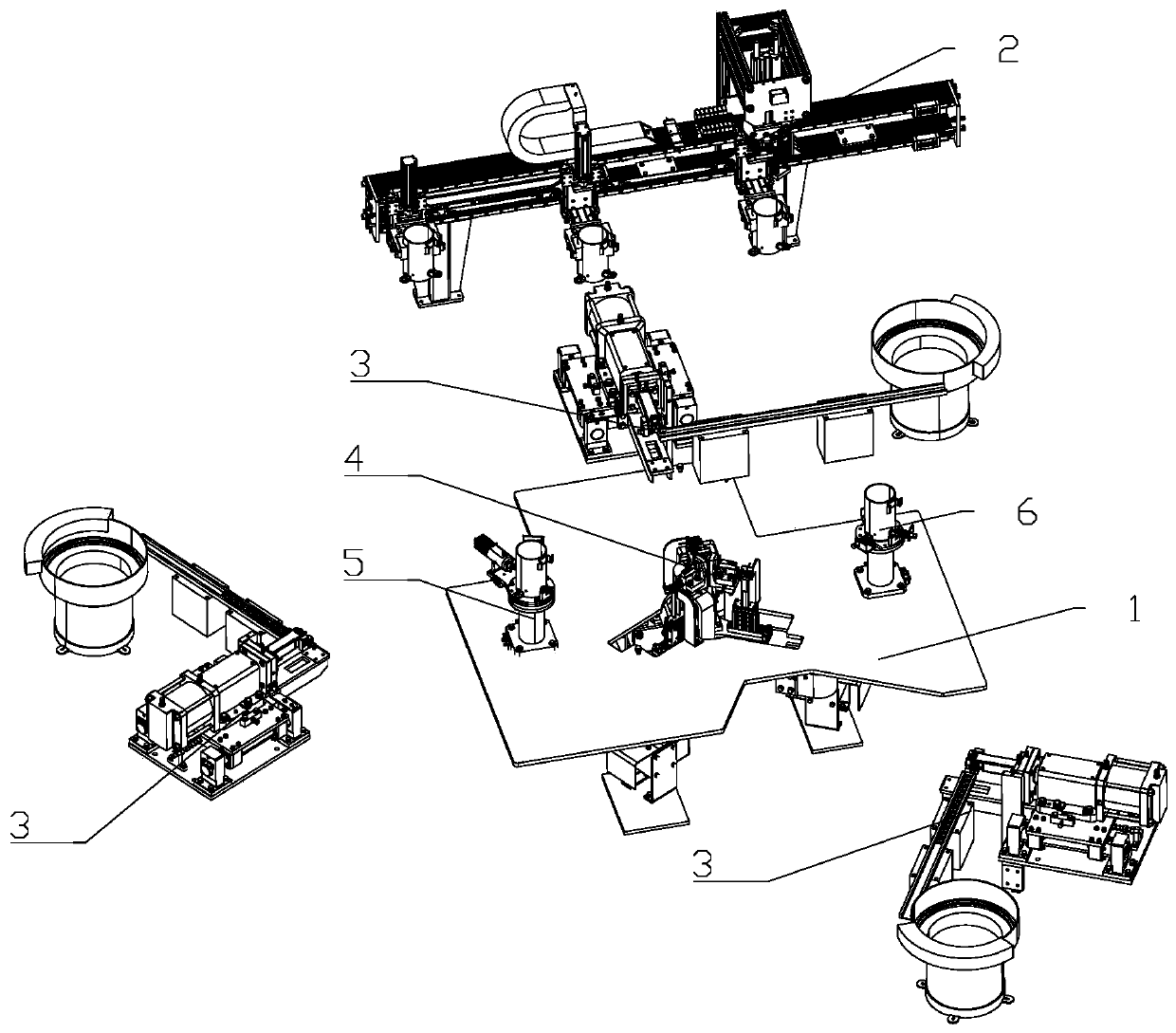

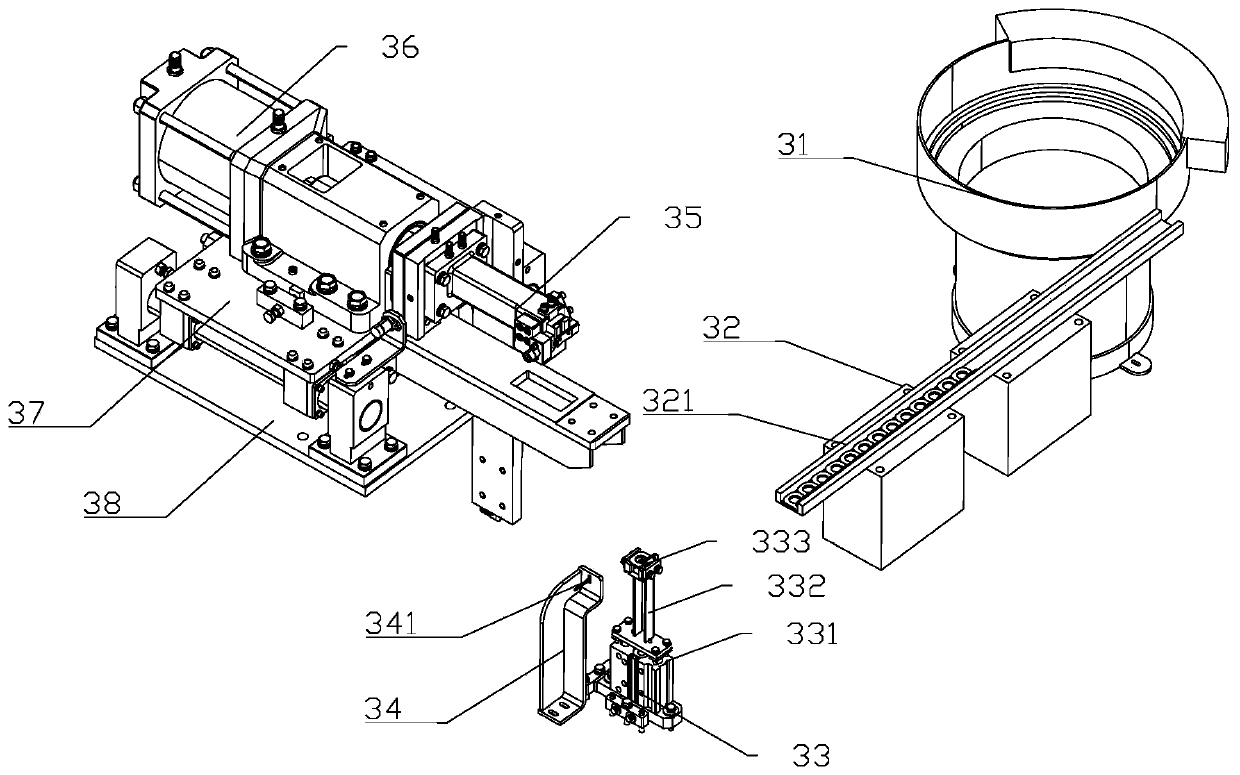

[0032] like figure 1As shown, a wire harness threading pipe welding machine includes a frame 1 and a pipe handling device 2 installed on the frame 1, a connecting ear feeding device 3, a pipe fixture device 4, a feeding seat assembly 5 and a feeding seat assembly 6. The connecting ear feeding device 3 is evenly arranged on the outer periphery of the pipeline fixture assembly 4, and the above-mentioned loading seat assembly 5 and unloading seat assembly 6 are installed on both sides of the pipeline fixture assembly 4. The pipe handling device 2 described above is located above the pipe fixture assembly 4 , the detection blanking assembly 5 and the blanking seat assembly 6 .

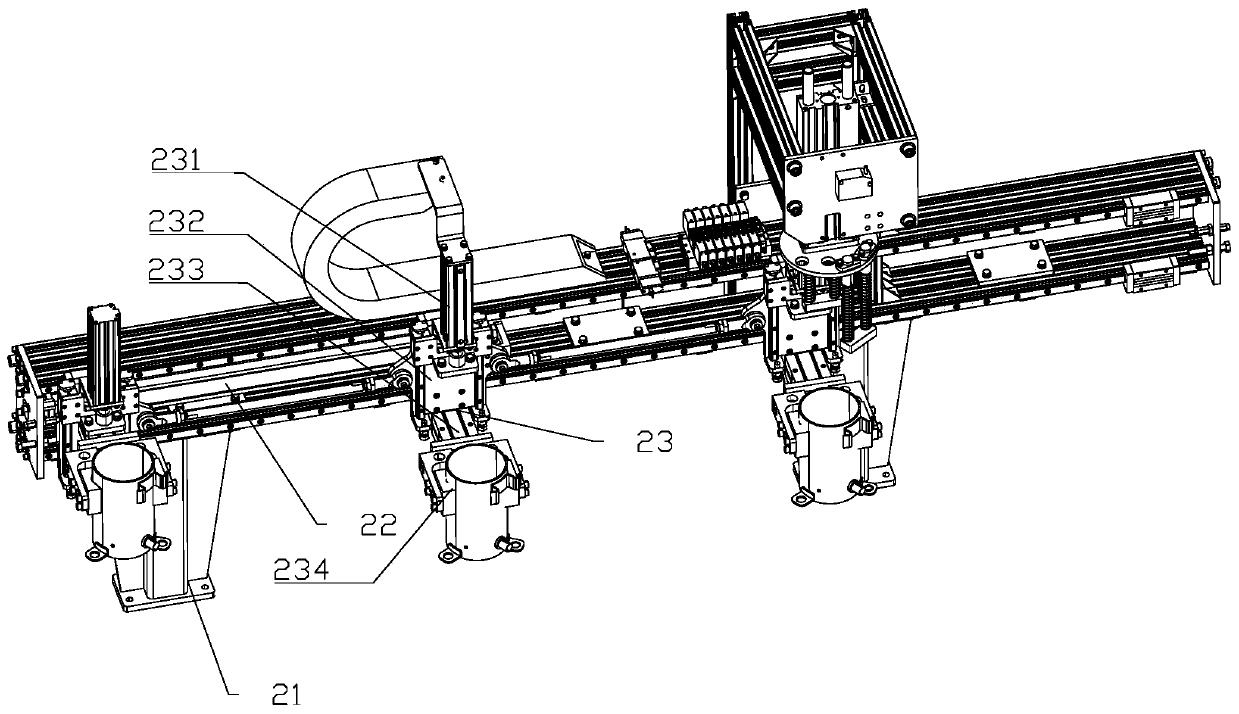

[0033] The pipeline handling device 2 is used for loading and unloading the pipeline; the pipeline fixture device 4 is used for positioning and clamping the pipeline to be welded, and the connecting ear feeding device 3 is used for The connecting ear is used for loading; the connecting ear feeding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com