Preparation method of blended modified polysulfone charged nanofiltration membrane and obtained membrane

A blending modification and nanofiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as secondary pollution, harsh modification process, and poor stability of the modified layer, and achieve Avoid poor stability, strong tolerance, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

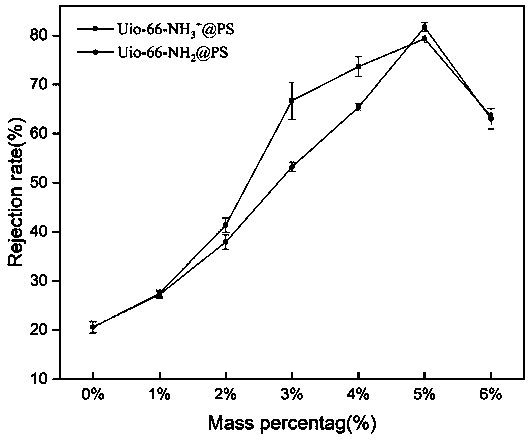

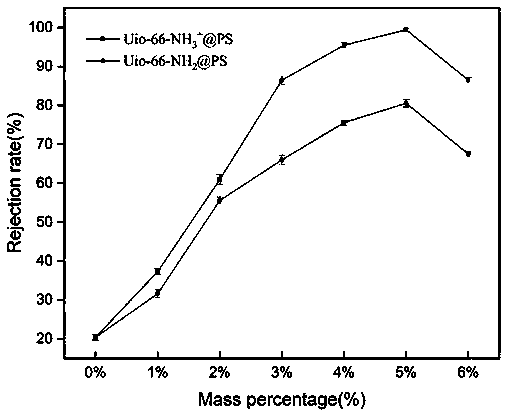

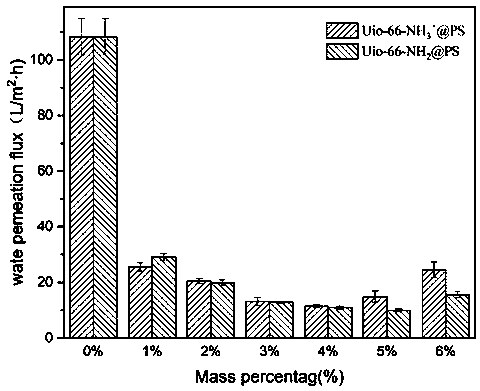

Image

Examples

Embodiment 1

[0042] Prepare a modified nanofiltration membrane 1 according to the following steps:

[0043] (1) UiO-66-NH 2 preparation of

[0044] Use an analytical balance to weigh 0.125g of zirconium chloride and place it in a 100mL round-bottomed flask, add 5mL of N,N-dimethylformamide and 1mL of concentrated hydrochloric acid with a pipette gun, and place the round-bottomed flask in an ultrasonic cleaner for ultrasonic cleaning. until the solid is completely dissolved. Then add accurately weighed 0.136g of 2-aminoterephthalic acid and 10mL of N,N-dimethylformamide, and sonicate again to dissolve the solid. Put the rotor into the round-bottom flask, stir in an 80°C oil bath for 5 hours, then take it out and centrifuge, wash the precipitate with methanol, repeat three times, and then dry it in an oven. Put the dried sample into a 100mL beaker, add 80mL acetone and let it soak for 72h, and replace the acetone solution every 12h to realize the activation of UiO-66.

[0045] (2) UiO-66...

Embodiment 2

[0051] Prepare a modified nanofiltration membrane 3 according to the following steps:

[0052] (1) UiO-66-NH 2 preparation of

[0053] Use an analytical balance to weigh 0.125g of zirconium chloride and place it in a 100mL round-bottomed flask, add 5mL of N,N-dimethylformamide and 1mL of concentrated hydrochloric acid with a pipette gun, and place the round-bottomed flask in an ultrasonic cleaner for ultrasonic cleaning. until the solid is completely dissolved. Then add accurately weighed 0.136g of 2-aminoterephthalic acid and 10mL of N,N-dimethylformamide, and sonicate again to dissolve the solid. Put the rotor into the round-bottom flask, stir in an 80°C oil bath for 5 hours, then take it out and centrifuge, wash the precipitate with methanol, repeat three times, and then dry it in an oven. Put the dried sample into a 100mL beaker, add 80mL acetone and let it soak for 72h, and replace the acetone solution every 12h to realize the activation of UiO-66.

[0054] (2) UiO-66...

Embodiment 3

[0073] Prepare a modified nanofiltration membrane 2 according to the following steps:

[0074] (1) UiO-66-NH 2 preparation of

[0075] Use an analytical balance to weigh 0.125g of zirconium chloride and place it in a 100mL round-bottomed flask, add 5mL of N,N-dimethylformamide and 1mL of concentrated hydrochloric acid with a pipette gun, and place the round-bottomed flask in an ultrasonic cleaner for ultrasonic cleaning. until the solid is completely dissolved. Then add accurately weighed 0.136g of 2-aminoterephthalic acid and 10mL of N,N-dimethylformamide, and sonicate again to dissolve the solid. Put the rotor into the round-bottom flask, stir in an 80°C oil bath for 5 hours, then take it out and centrifuge, wash the precipitate with methanol, repeat three times, and then dry it in an oven. Put the dried sample into a 100mL beaker, add 80mL acetone and let it soak for 72h, and replace the acetone solution every 12h to realize the activation of UiO-66.

[0076] (2) UiO-66...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com